19.09.2025

Friends, partners, and like-minded persons! On September 20, we celebrate the anniversary of our company - SIC AGRO-SIMO-MASHBUD! It was 33 years of productive work, discoveries, practical achievements, research, and success! And how could such success be possible without you?! Therefore, today, dear friends, It's time to open the curtains of our scientific-industrial corporation and share with you some of our achievements and interesting facts.

So, in the early 1990s, the company began manufacturing its first technological machines for grain cleaning and hydrothermal treatment of grain. Well, it was a young company... First orders, first supplies – some machines were delivered to the customer their own means, almost by hand and accompanied by specialists. At the same time, a powerful design and engineering department is being created, where the company's ‘'brain centre’’ is concentrated. "Creative" has become important word! This department brought together both experienced experts in the fields of science, mechanical engineering and manufacturing, and young, energetic university graduates with a fresh perspective and approach.

After only five years of operation, AGRO-SIMO-MASHBUD designed and installed a turnkey buckwheat processing mill in Ukraine - a successful and fruitful project! This experience has demonstrated that the company can organise the entire cycle of constructing an excellent grain mill – from planning and designing production lines to supervising assembling and commissioning. At the same time, the company was getting loads of requests to upgrade old production lines for cereals, flakes, and flour. And the enterprise fulfilled these tasks excellently – it means, after a complete audit of the facilities, we proposed and installed updated lines equipped with the newest equipment, taking into account modern requirements for the quality of the finished product. These processing lines are still operating successfully today! By the way, of the 141 grain production lines we have built and equipped, 65 are buckwheat processing plants. Buckwheat plants are characterised by high yields of finished products. According to standard technology and in accordance with the Rules for Conducting Technological Processes the yield is 69% (kernels + broken grains) at such grain mills, while using our technology, with the base quality of the initial buckwheat grain, the yield is 74%!

Our employees have always been particularly excited about new projects. Leading specialists monitored each stage and were able to identify process bottlenecks (weakspots) based on the appearance of the finished product in the workshop exactly. Over the years, the care and attention have not gone away, but practical experience has been added, and the range of equipment and services offered has expanded. Thanks to its high level of employees` professionalism, the volume of products manufactured and the number of turnkey grain processing complexes built, the company's team has received a range of well-earned awards and certificates, including for its significant contribution to the development of the grain processing industry. In 1997, one of our company's leading specialists was awarded the honorary title of ‘Honoured Inventor of Ukraine’ by the President of Ukraine.

In the 2000s, the AGRO-SIMO-MASHBUD developed its foreign economic department, and equipment exports gained ground. And in 2012, the company was named “Exporter of the Year”.

We would like to point out our original developments! Modern technologies and methods of production process management make enterprises be flexible and able to adapt quickly, So, the company's designers and engineers keep an eye on current trends and respond very quickly to new market developments, creating unique, proprietary machines for processing of grain and legumes. For example, seven different types of steamers are manufactured exclusively for the hydrothermal treatment of grain by steam.

Almost every year, two or three new machines arise from the drawings of our experienced designers. Many partners and customers are already familiar with our authorship equipment in practice:

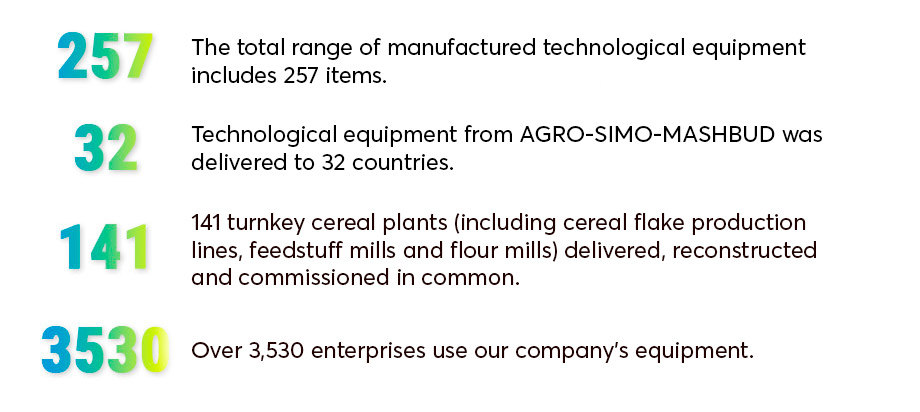

Some facts about us for 2025:

Enterprises that use our equipment today, are bread-baking plants, cereal factories, cereal flake production lines, mills, feedstuff production, distilleries, legume product manufacturers, infant food factories, confectionery sunflower seed processing lines, oatmeal production lines, oil and fat production and extraction plants, starch and syrup plants, and bioethanol production plants.

A great advantage of our company is that the equipment manufacturing process takes place at three independent production sites! It allows the equipment manufacturing process to be accelerated as much as possible. Each enterprise has its own specialisation in product range production. And each of them can simultaneously produce up to 50% of the total product range. Production facilities are located in three regions of Ukraine. The newest facility was launched two years ago in the Zhytomyr region. It is equipped with modern powerful laser cutters (12 kW, metal thickness up to 45 mm) and CNC machines. In addition to minimising delivery times, this also reduces logistics costs for our customers.

There are difficult times, but in contrast to such times, there are the ability to work, inspiration, ambitions and desire! Our company has come a long way in 33 years, from its founding to becoming a successful leader in grain processing technology. And we have come this exciting way thanks to our wonderful team, reliable partners, clients and customers. We extend our heartfelt gratitude to everyone for your trust and support, because thanks to you we have been working hard, developing and reaching new heights all these years!

We take great pride in the following facts:

- we implement modern technologies that meet the highest standards of efficiency and safety;

- we are developing Ukrainian manufacturing by keeping stability and trust among our customers;

- we are building a team of professionals who implement engineering solutions that change the industry on a day-to-day basis.

And much more is to follow! Time to keep moving forward. We are energised by effective solutions based on the best practice, we look confidently to the future, and continue to improve.