Українська версія сайту

Ви завжди зможете переключити мову сайту, скориставшись перемикачем.

Scientific-industrial corporation

AGRO-SIMO-MASHBUD

company with limited responsibility

- About us

- Equipment

- Grain cleaning

- Grain fractionation and sorting

- Hydrothermal Grain Processing (TRP)

- Peeling and grinding grain

- Milling and grinding grain

- Grain crushing and drying

- Modular plants

- Grain crushing and mixing feed

- Transportation

- Aspiration and ventilation

- Color sorters

- Scales, dispensers and packaging

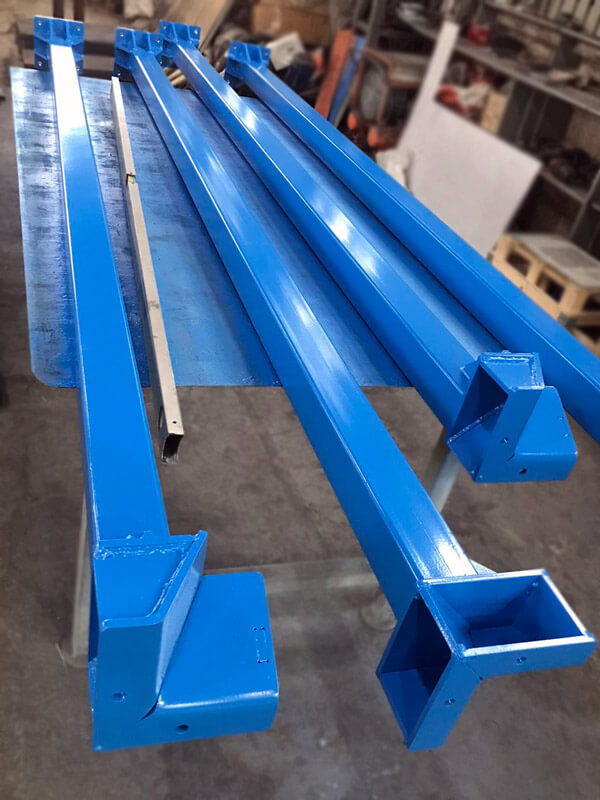

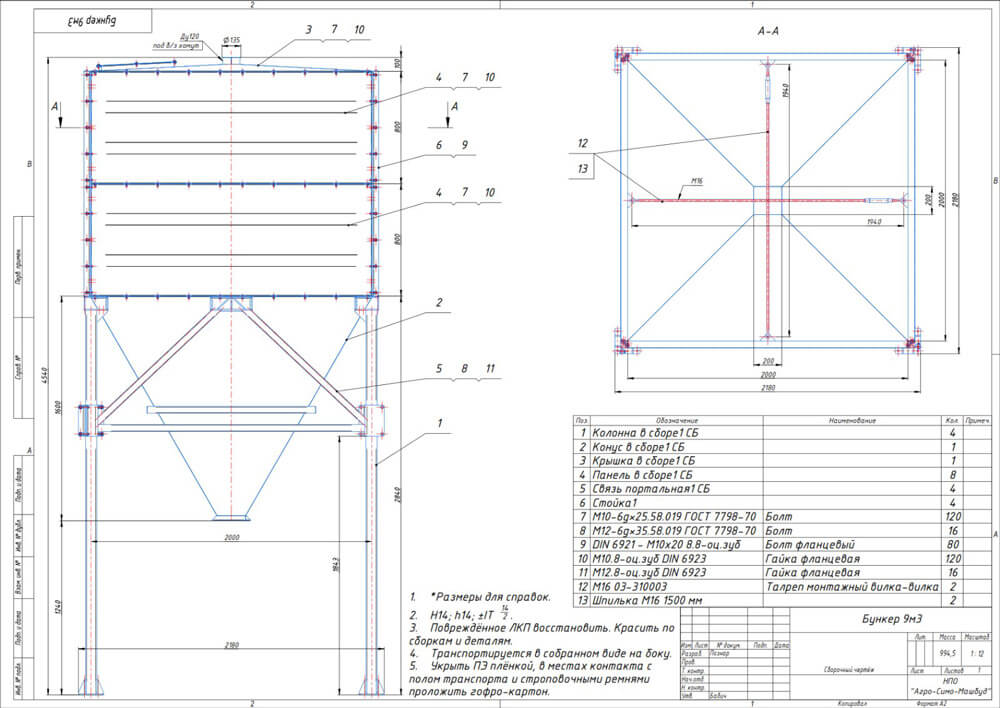

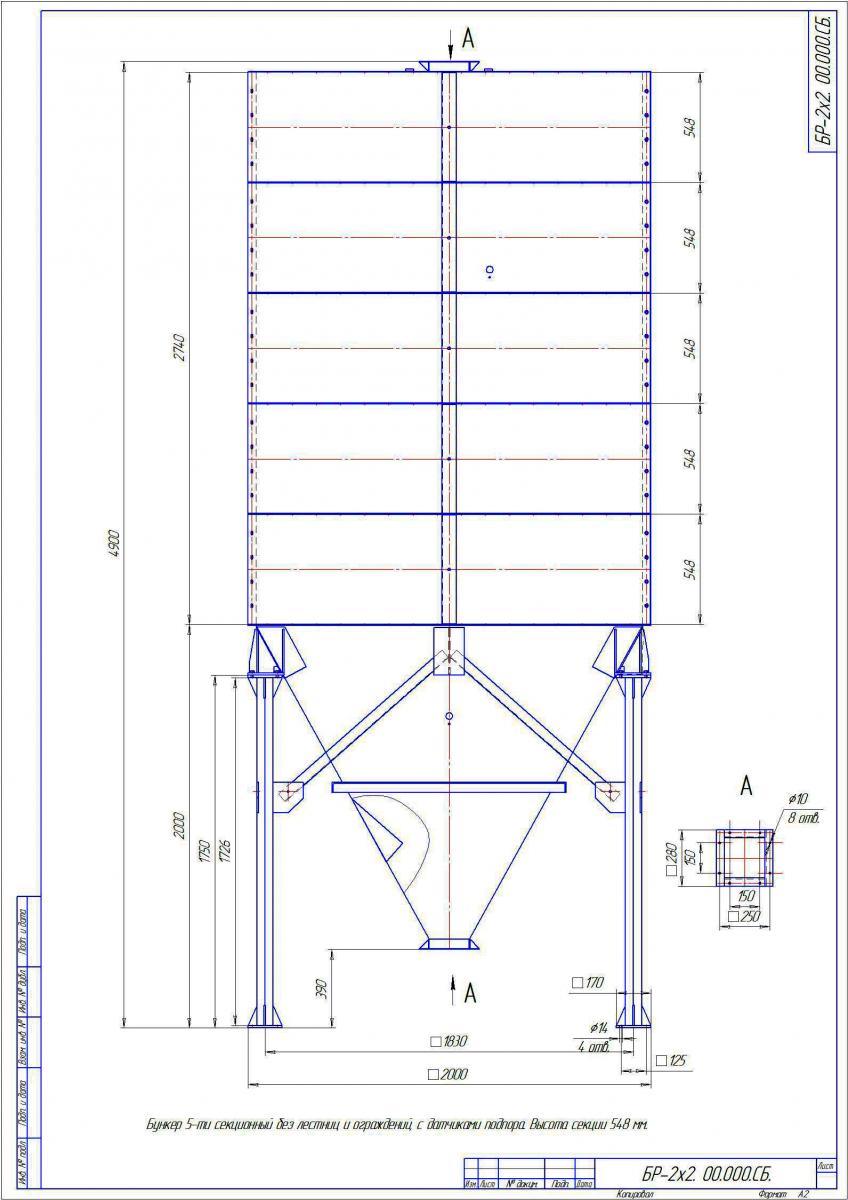

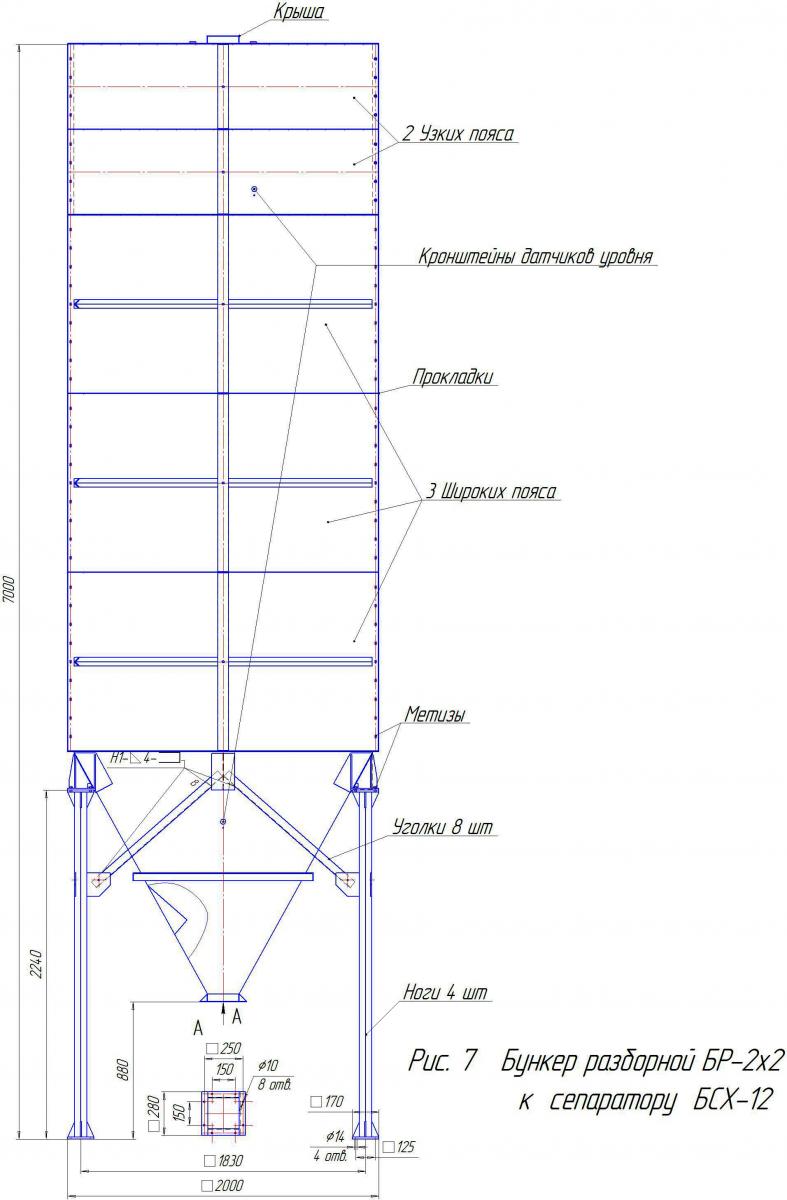

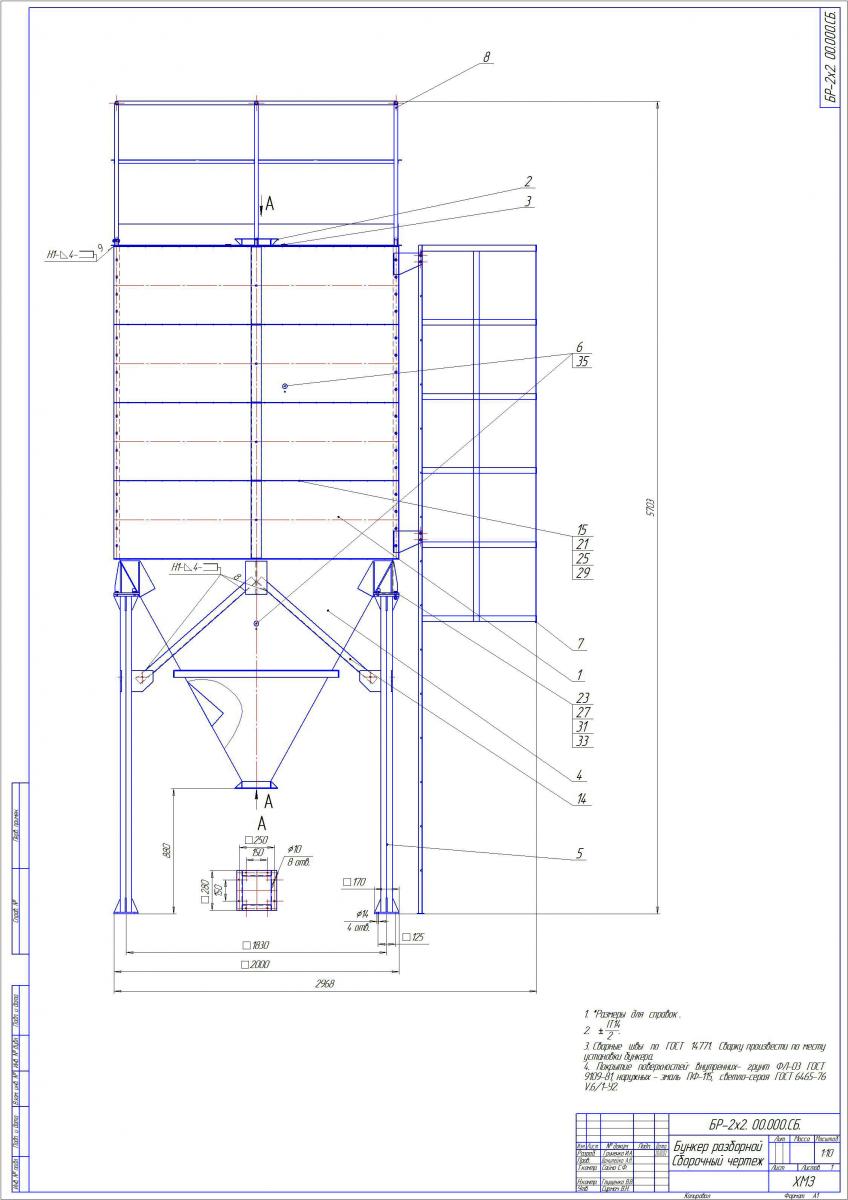

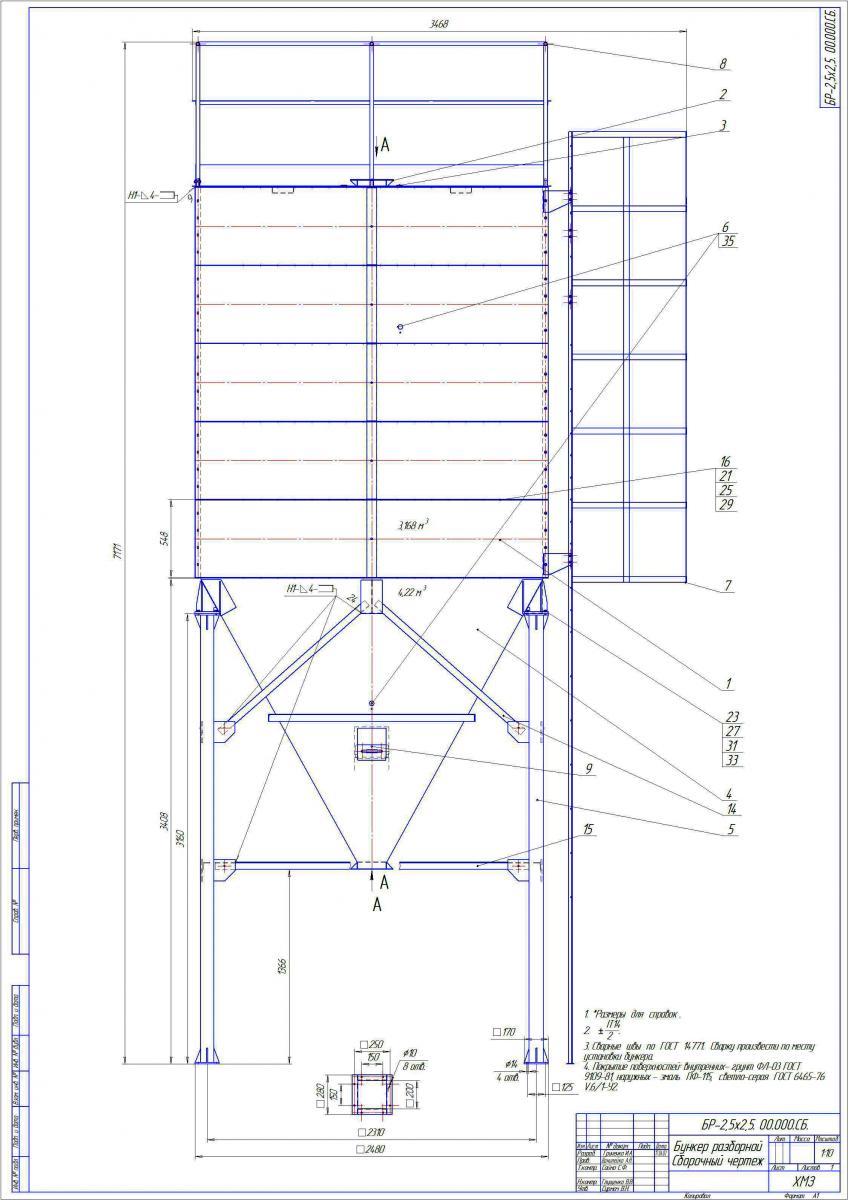

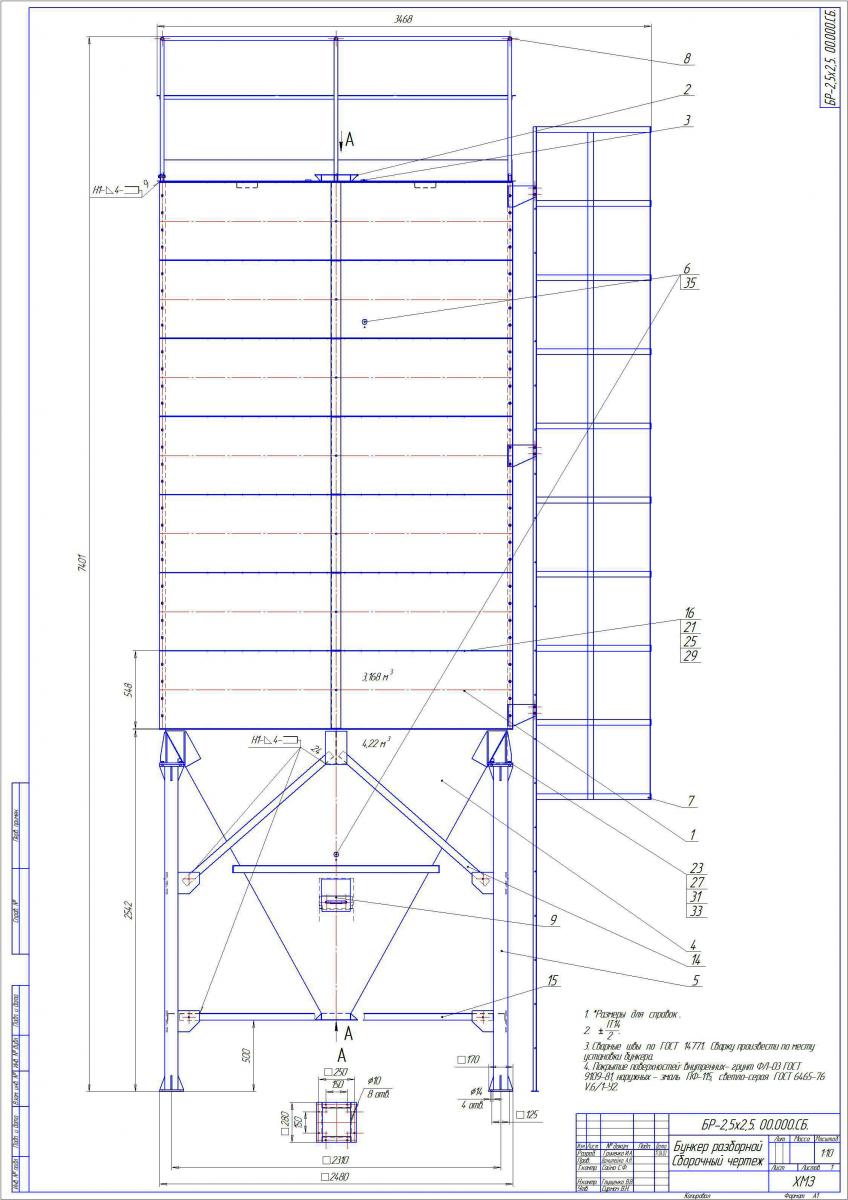

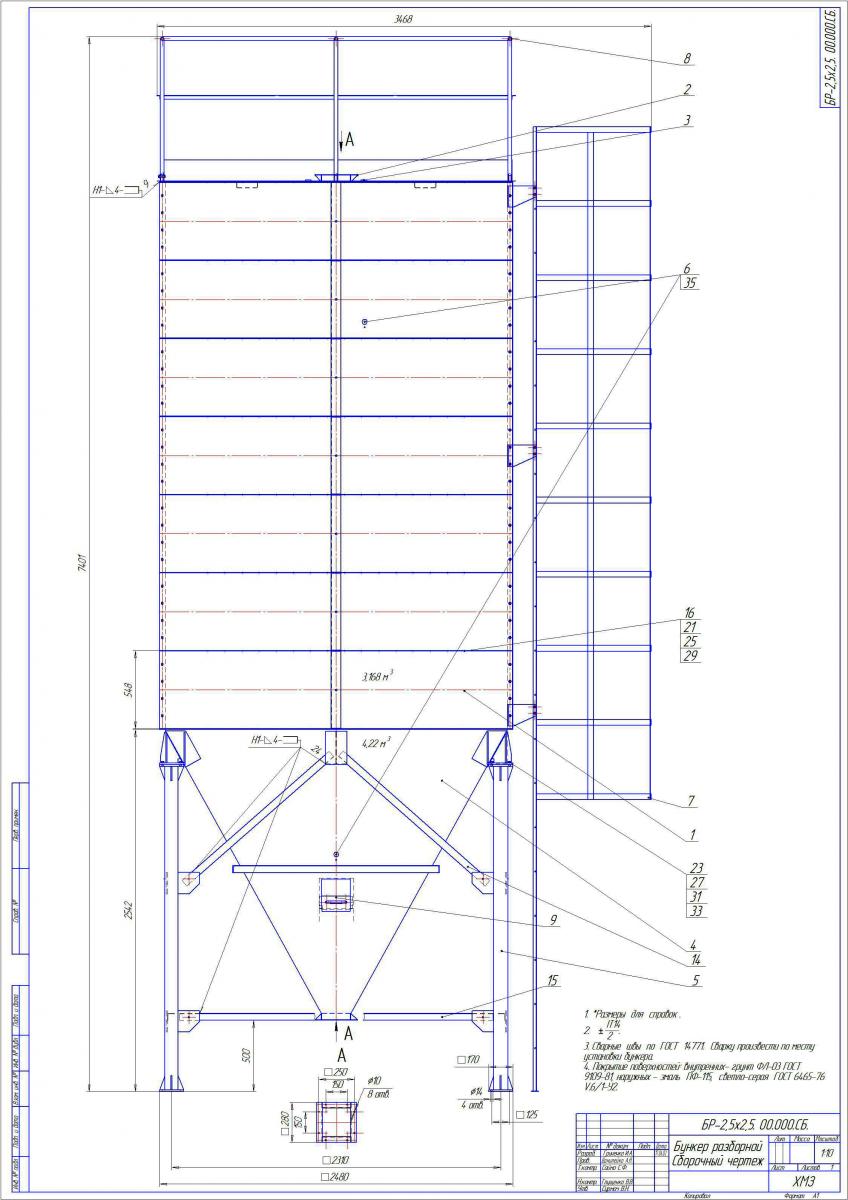

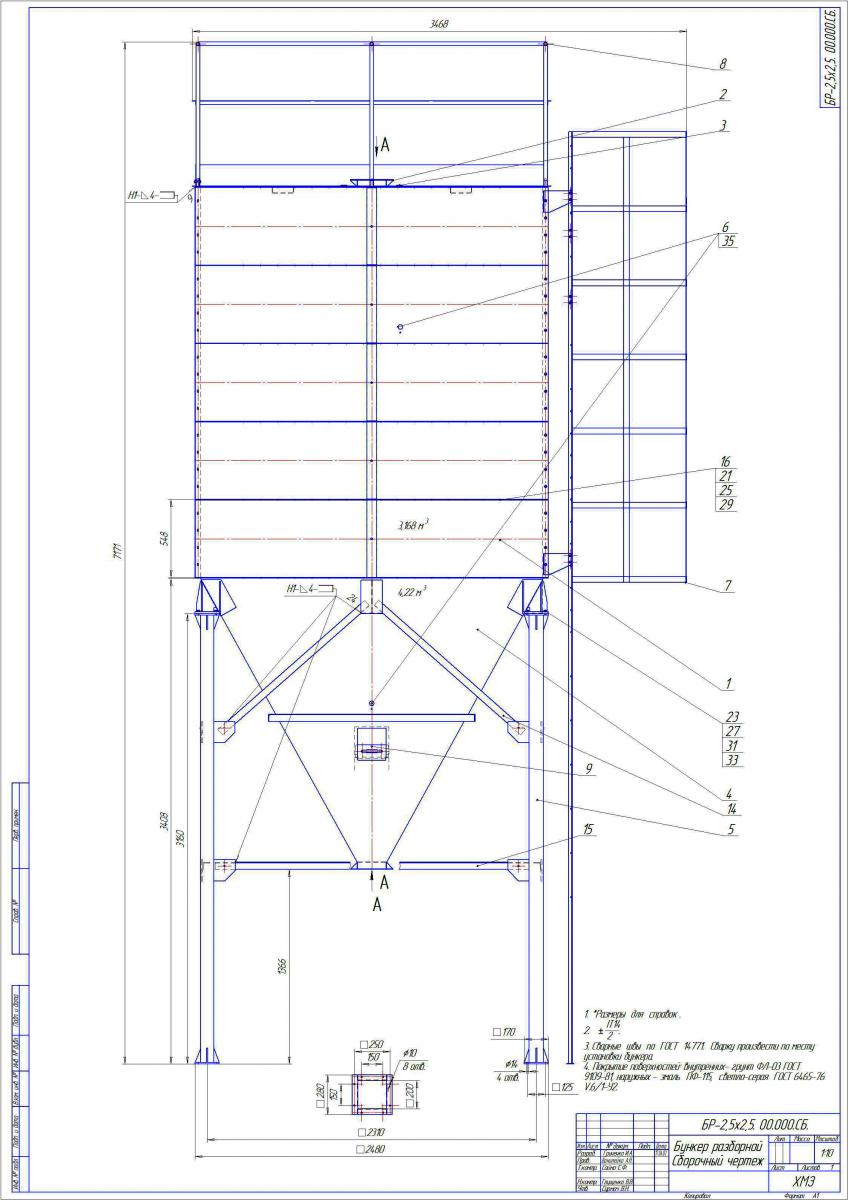

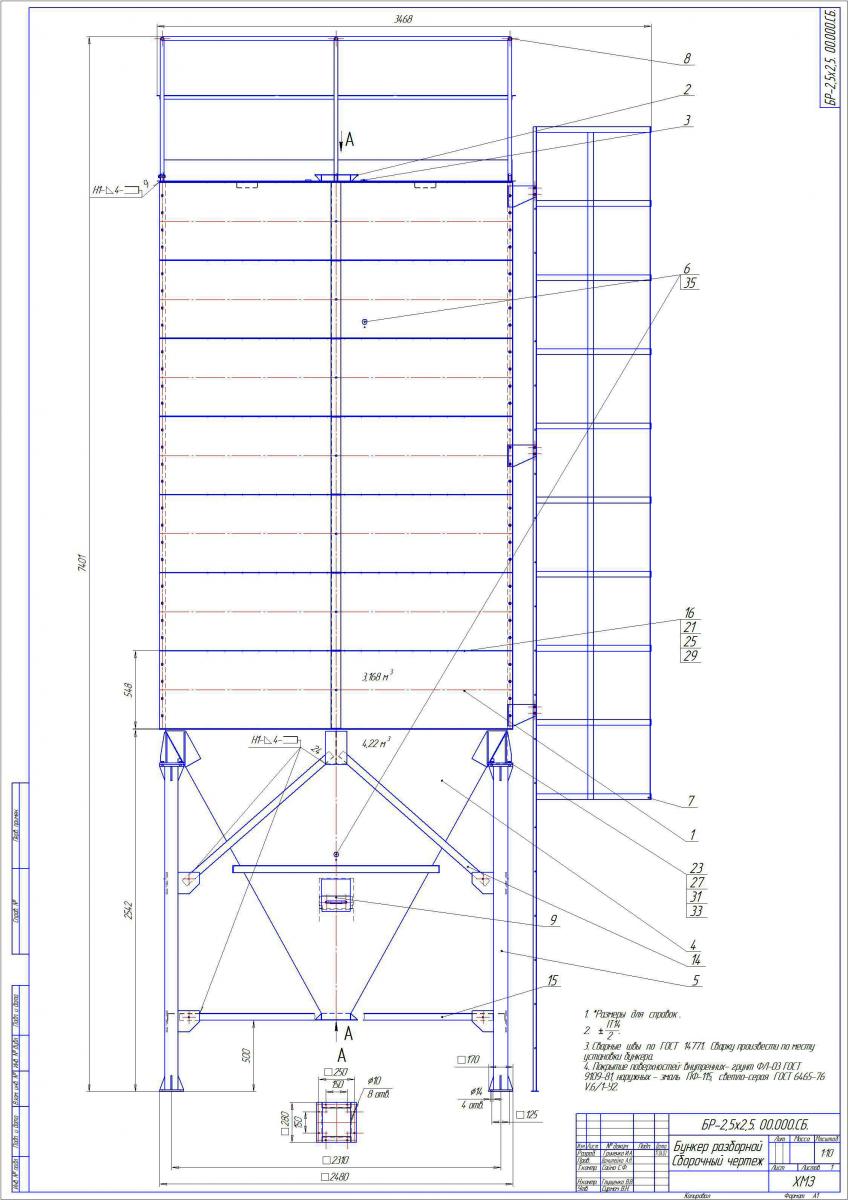

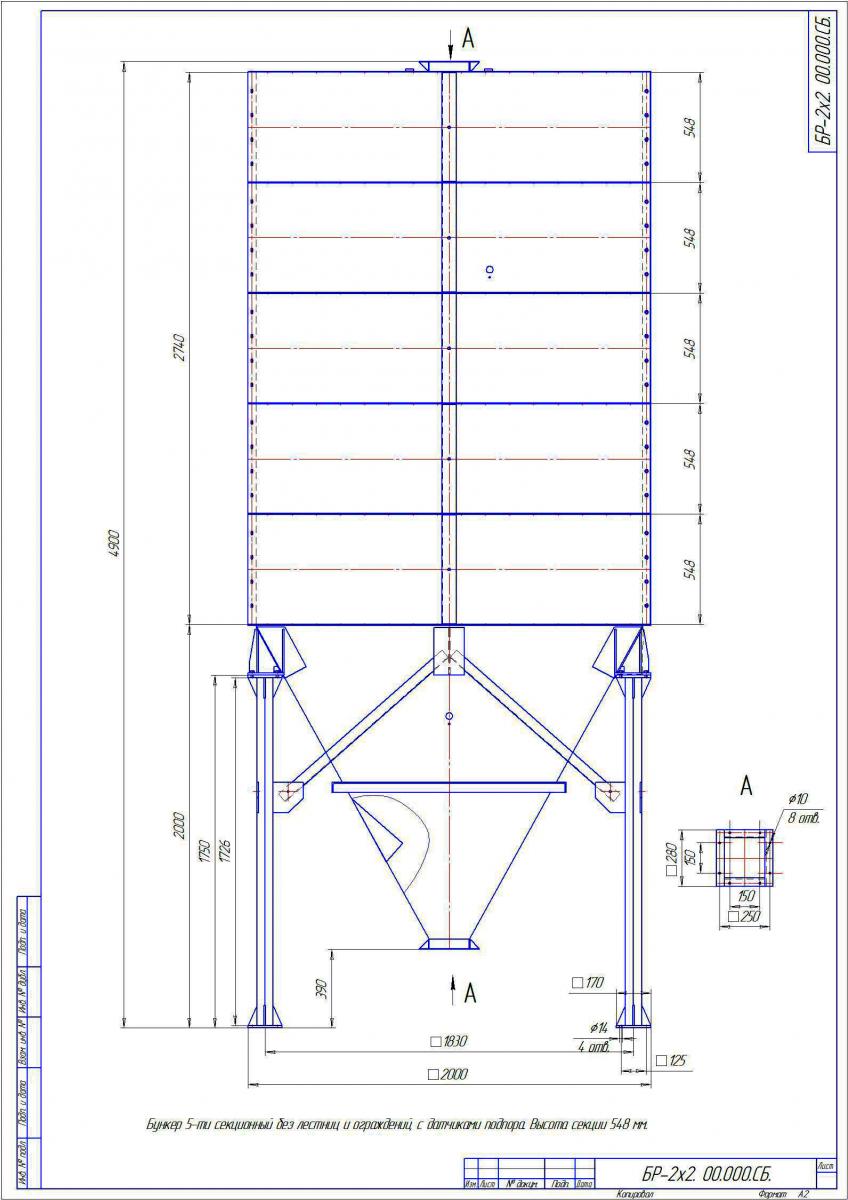

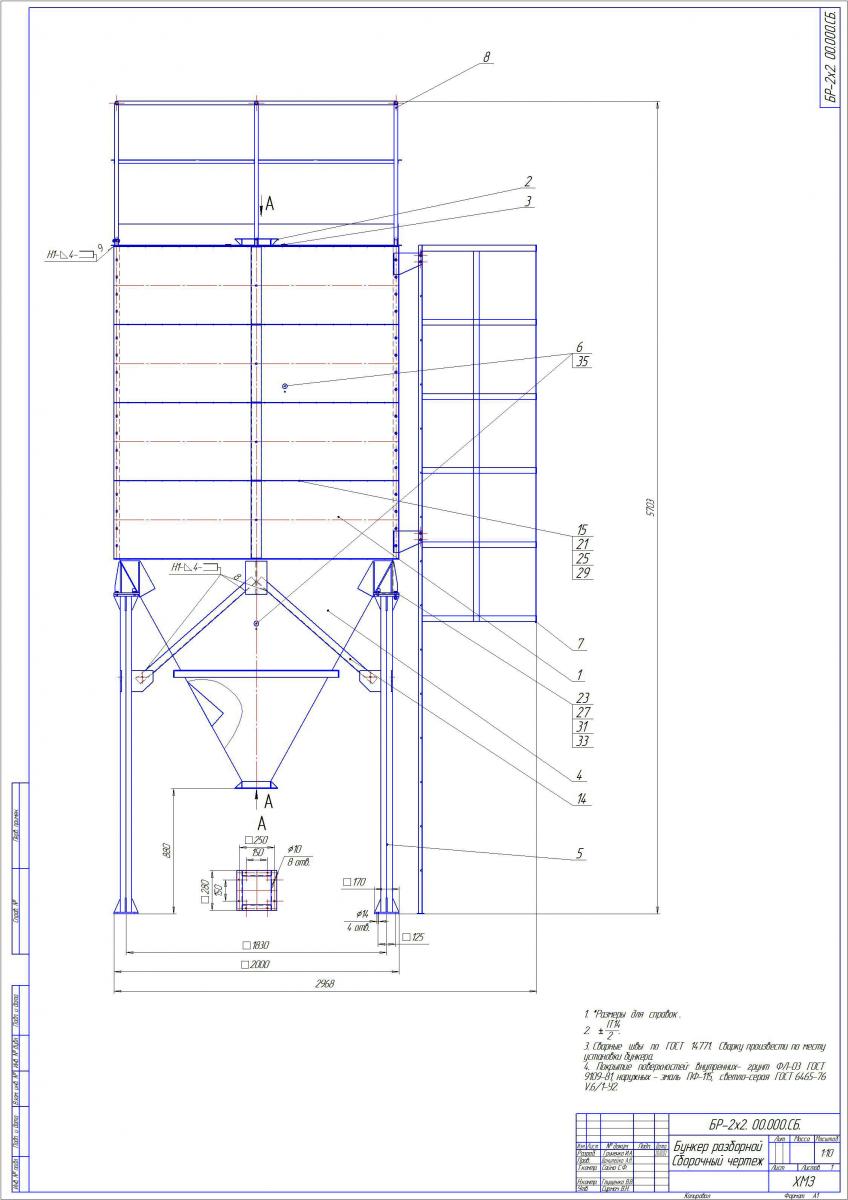

- Bunkers

- Equipment for oil and fat extraction industry

- Parts and accessories

- Turnkey plants

- Services

- Our projects

- News

- Contacts

- About us

- Equipment

- Grain cleaning

- Grain fractionation and sorting

- Hydrothermal Grain Processing (TRP)

- Peeling and grinding grain

- Milling and grinding grain

- Grain crushing and drying

- Modular plants

- Grain crushing and mixing feed

- Transportation

- Aspiration and ventilation

- Color sorters

- Scales, dispensers and packaging

- Bunkers

- Equipment for oil and fat extraction industry

- Parts and accessories

- Turnkey plants

- Services

- Our projects

- News

- Contacts