Purpose:

Hose filter ФP is designed to finish clear air, which flows out of the equipment through aspiration system of elevators, mills, cereal and feed-staff processing lines. The filter can be supplied as independent equipment. In aspiration and pneumatic transport systems, the filter can be installed at the outlet of the basic fan. No ozone-depleting substances or flourescent greenhouse gases are used (absent) in this equipment.

Specifications:

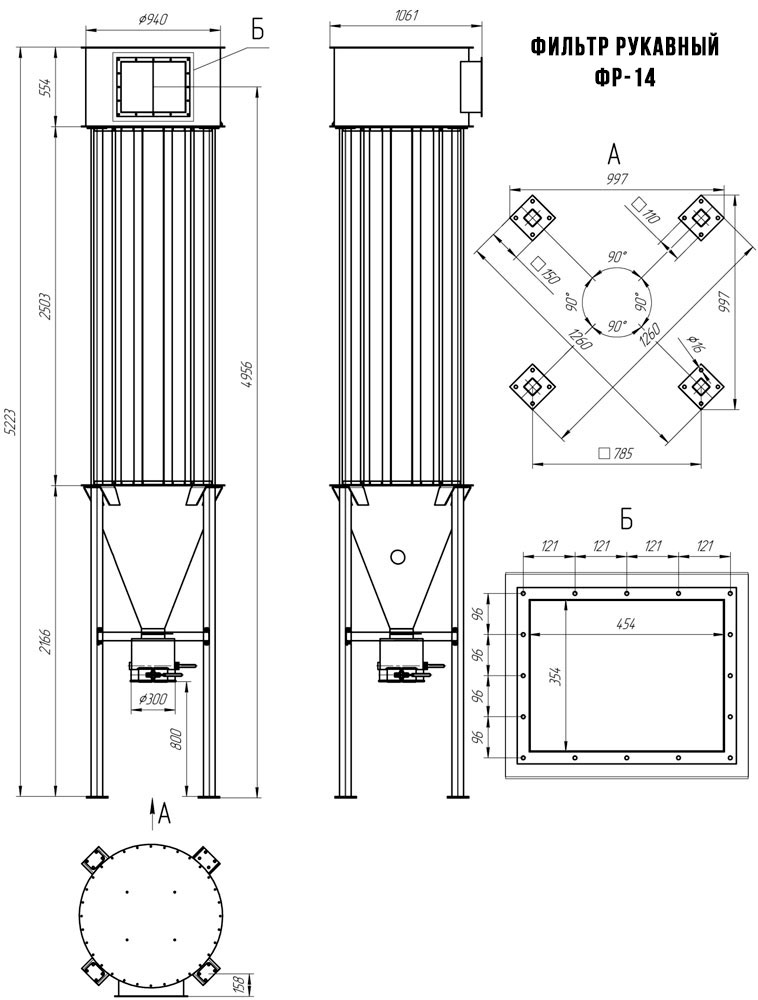

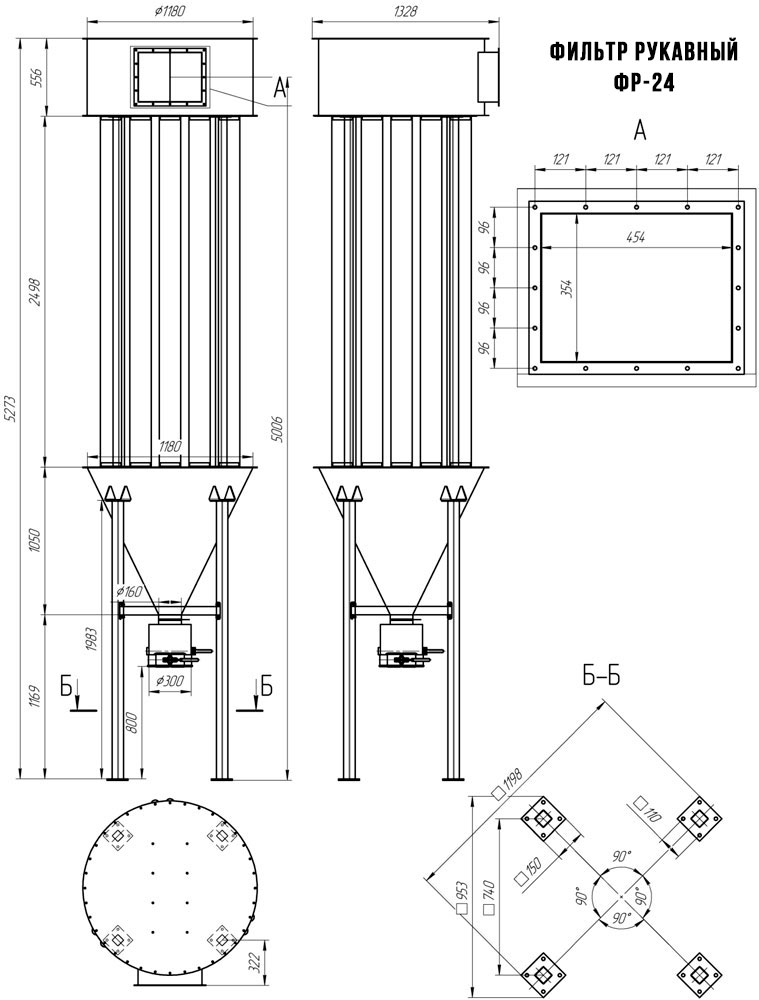

| Indicator name |

ФР-14 |

ФР-20 |

ФР-24 |

| 1. Cleaning ratio, minimum |

0,99 |

| 2. Total area of filtering surface, m2 |

18 |

25 |

28 |

| 3. Number of filtering hoses, pcs |

|

| - Ø 120 |

|

|

12 |

| - Ø 160 |

14 |

20 |

12 |

| 4. Nominal aerodynamic load on the material, m3/m2min |

3,5 |

| 5. Aerodynamic resistance at nominal load, Pa, max. |

1 500 |

| 6. Dimensions when assembled, mm, max.: |

|

| - length |

1 061 |

1 328 |

1 328 |

| - width |

997 |

1 180 |

1 180 |

| - height |

5 223 |

5 273 |

5 273 |

Product composition and equipment set of delivery:

Hose filter ФP consists of cylindrical body with inlet nozzle, frame of filter with filtering hoses, cone with outlet device (which consists of nozzle and bag holder).

Complete set includes:

- Hose filter ФP - 1 pcs.;

- Passport ФР ПС - 1 pcs.;

Design and principal of operation:

Hose filter ФP consists of cylindrical body with inlet nozzle, frame of filter with filtering hoses, cone with outlet device (which consists of nozzle and bag holder).

The cylindrical body is metal structure, which has inlet nozzle for dusted air in the end part of the body. In the lower part of the cylinder, there are installed nozzles for fastening of the filtering hoses.

The frame of the filter is metal structure where installed cylinder and cone.

The cone is metal tank for dust storage. The cone has outlet device, which consists of nozzle with bag holder. There are nozzles for fastening of the filtering hoses in the upper part of the cone.

In the pneumatic system, the filter can be mounted behind the basic fan, if the fan made in intrinsically safe design.

The principal of operation. The dusted air goes to the body through the nozzle. Here it is partly dedusted due to the principle of pressure differential. Then the air goes out through hose material. Hoses cleaning is carried out manual. The separated dust goes to the cone and is cleaned manual periodically.

Cleaning intervals for hoses and cone are determined individually and depend on factors such as air dust content, particle size and equipment cycling.

Filter hoses are made of filter fabric (No 2) Арт.14506.