Purpose:

The grinding machine (degerminator) of the MП brand (hereinafter referred to as the machine) is intended for crushing (de-ordinating) the corn kernels to obtain germs of optimum quality with the maximum carotene content in the crushed material, as well as cereals and flour when working in production lines in enterprises.

The machine allows dry processing of grain, without resorting to the subsequent drying of the resulting products. The machine is intended for operation in areas with a temperate climate; it must be manufactured in a climatic version of category 3, according to GOST 15150.

Specifications:

| Parameter |

Degerminator MП |

| 1. Productivity, t/h |

3,0 |

| 2. Installed power, kW |

11,0 |

| 3. Rotor speed, rpm |

500 |

| 4. Internal diameter of the cylinder, mm |

700 |

| 5. The length of the cylinder, mm |

1 240 |

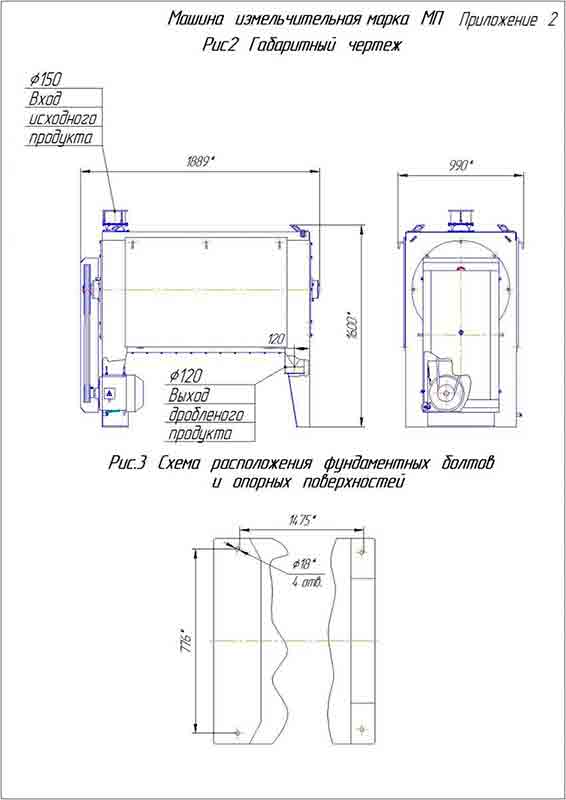

| 6. Overall dimensions, mm, not more than |

|

| - length |

1 810 |

| - width |

990 |

| - height |

1 710 |

| 7. Weight, kg |

432 |

Device and work:

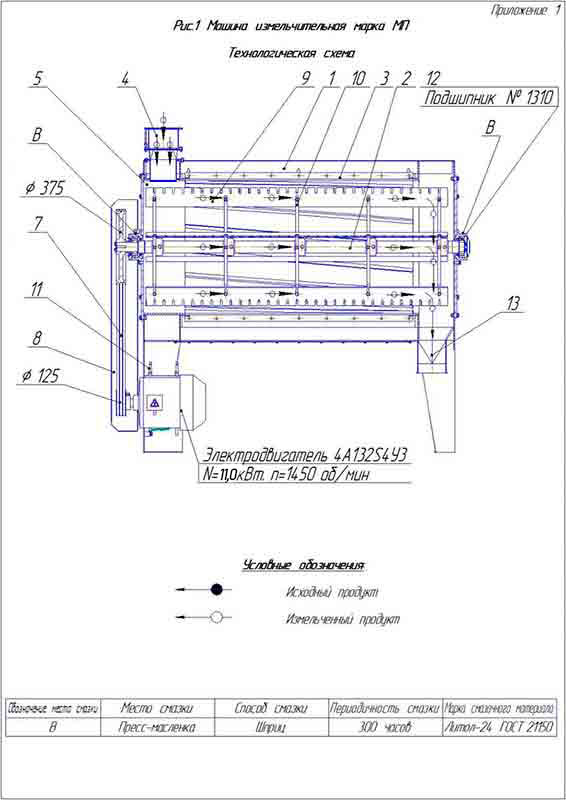

The machine consists of: body 1, rotor 2 with scourges 9, cylinder 3, receiving pipe 4, fencing 8, tensioning screw 11, support bearings 12, exhaust pipe 13 (Fig. 1).

In the housing 1 are the main body of the machine - the flail rotor 2. It has a shaft, crosses 10 and bichi 9. The rotor is installed in the bearing assemblies attached to the end walls of the housing 1 of the machine.

Rotation of the rotor is driven through a V-belt transmission. The drive uses standard lap motors with a power of 11.0 kW. The tension of the V-belts 7 is made with the help of tensioning screws 11. The product enters through the receiving nozzle 4, the feeder 5 into the working zone, where the product, with scourges 9, located on the crossings of the rotor 10, is reported to have both rotational and axial movement. The product is thrown by the whips of the rotor 9 to the fixed strips of the drum 3, which stop its movement. Due to the intense impact in the gaps between the shell and the rotor, the product is crushed. Using bent plates on the rotor crushed grain is moved and through the outlet 13 is removed from the machine.

Cylinder 3 consists of two halves connected in a horizontal plane, and is mounted on the feeder 5 and the inner wall of the casing of the machine 1. In order to even wear the surface, it is recommended to rotate the cylinder 3 180° during operation.