Purpose:

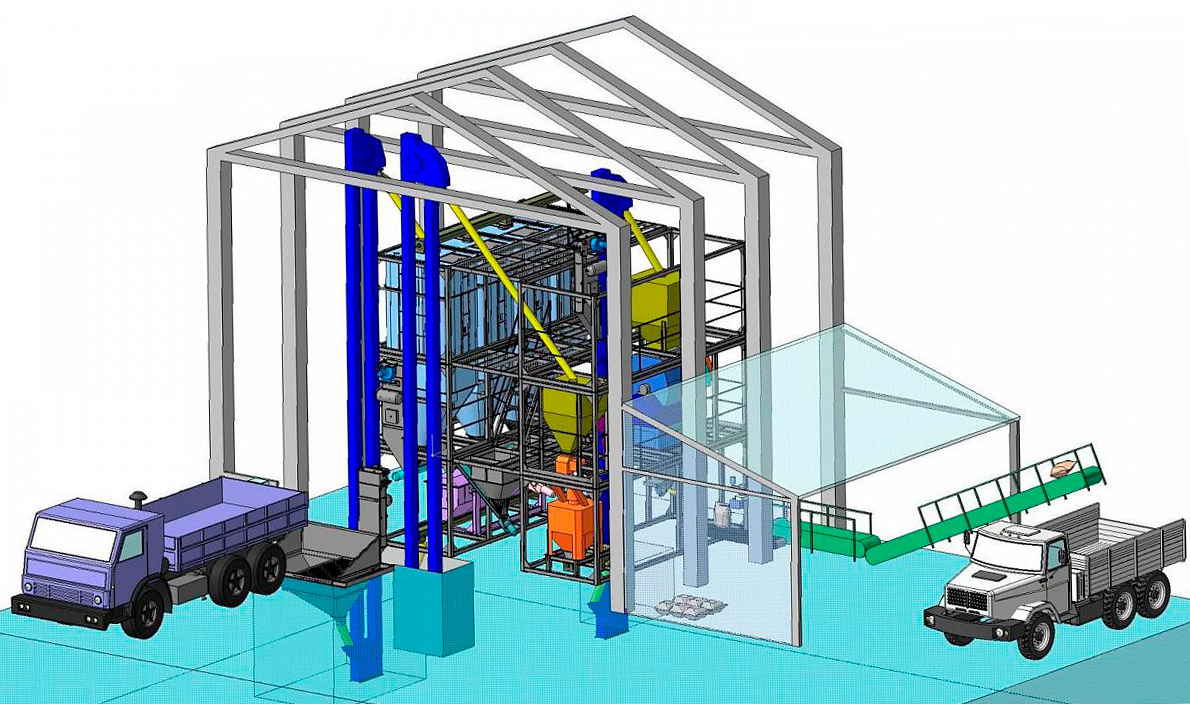

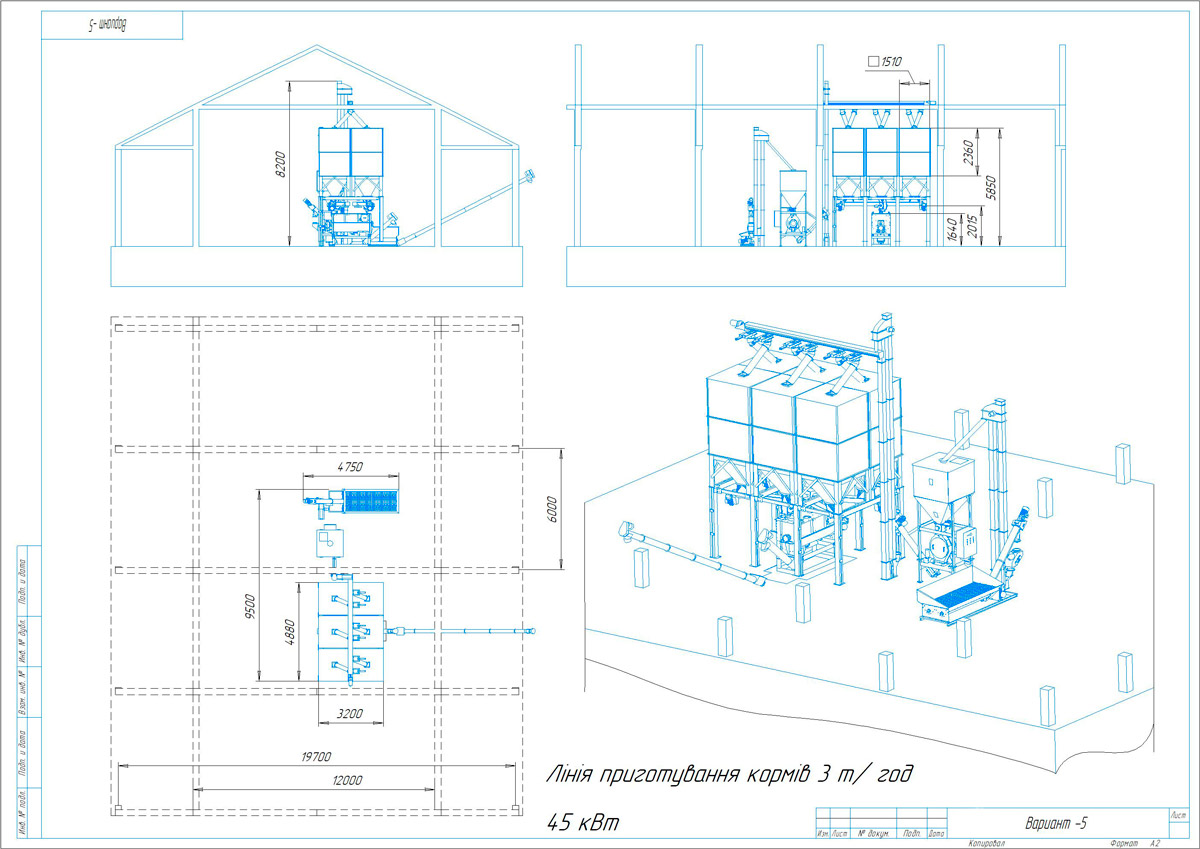

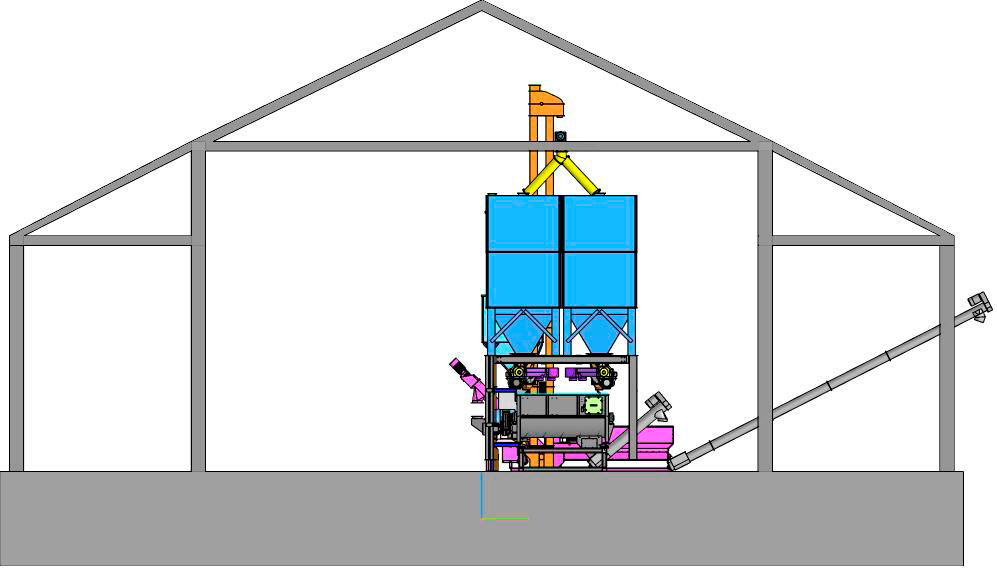

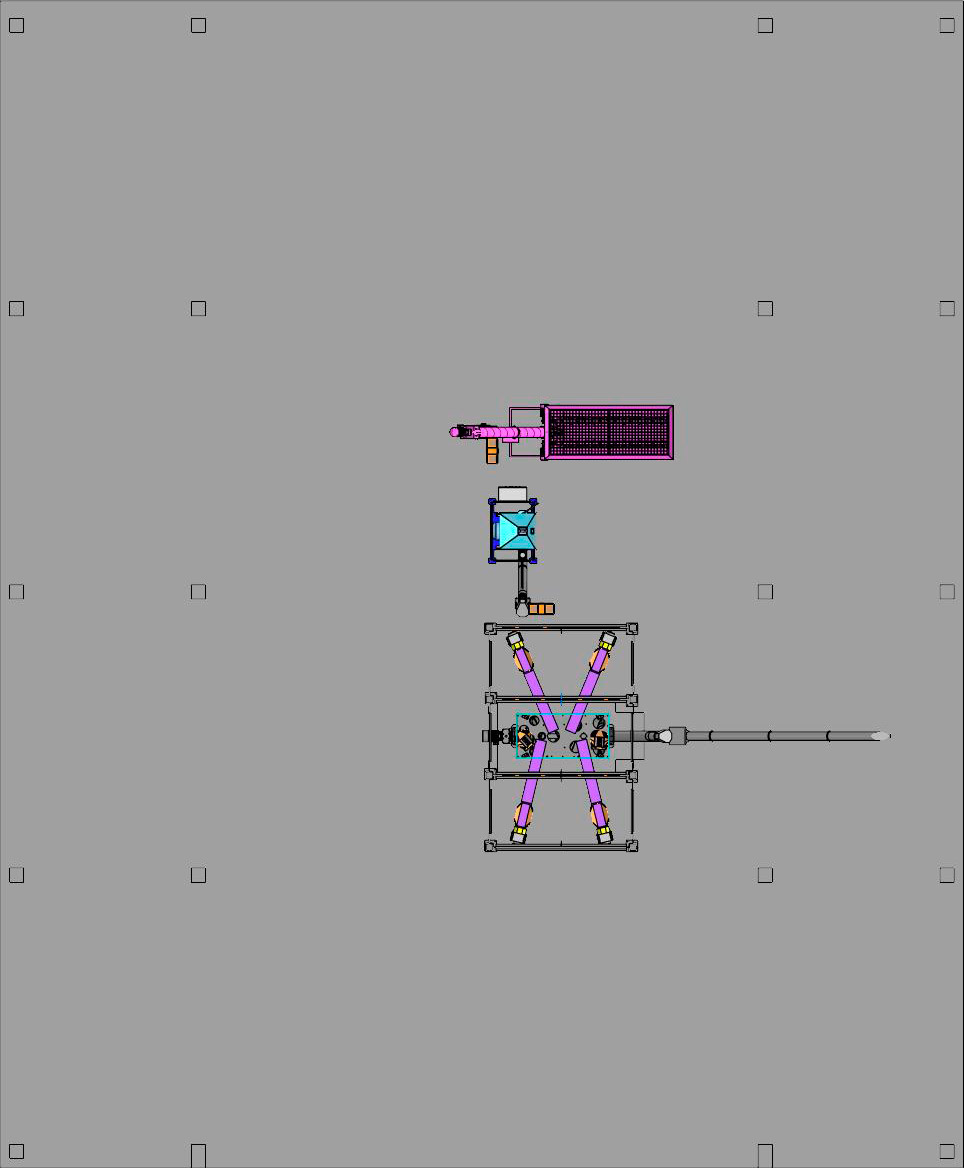

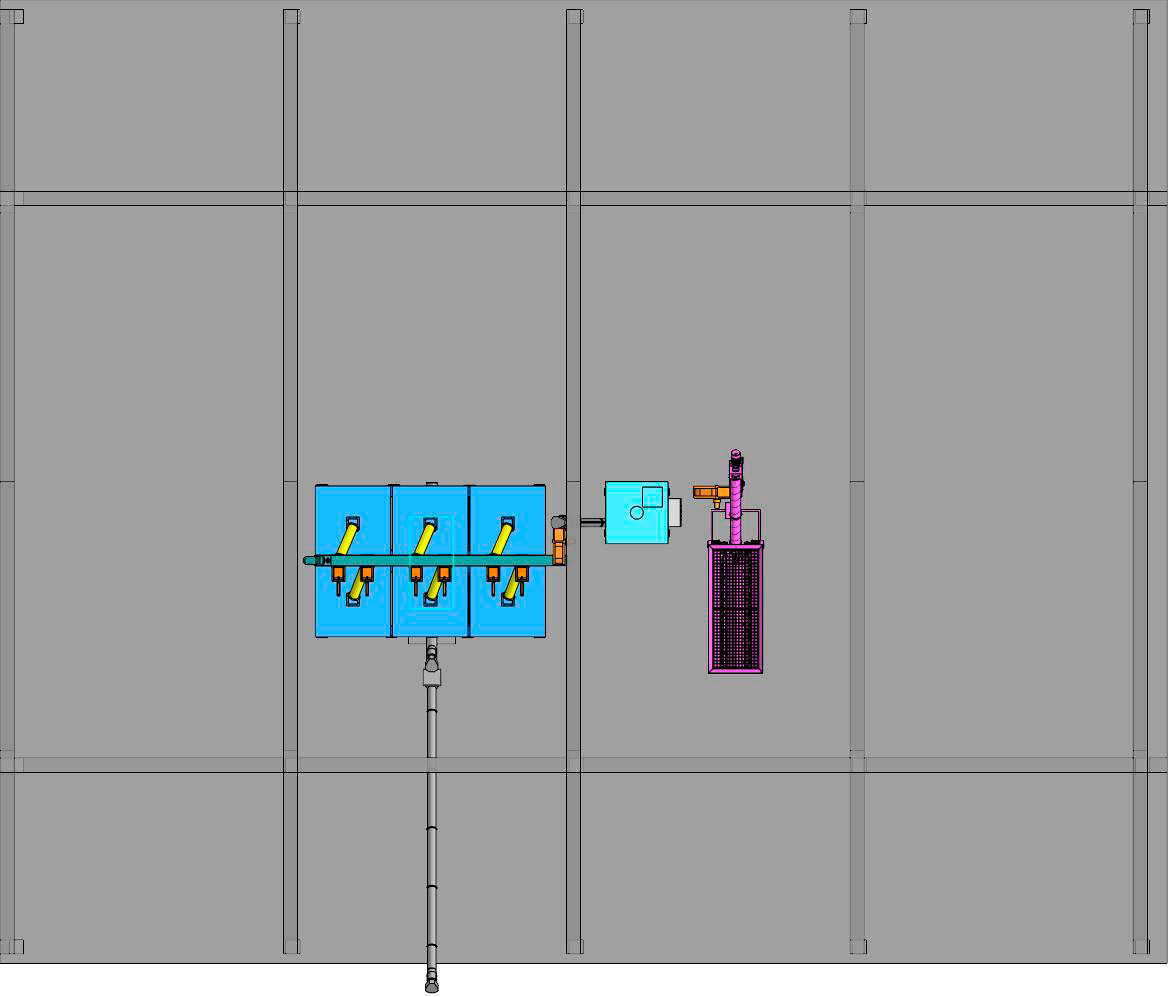

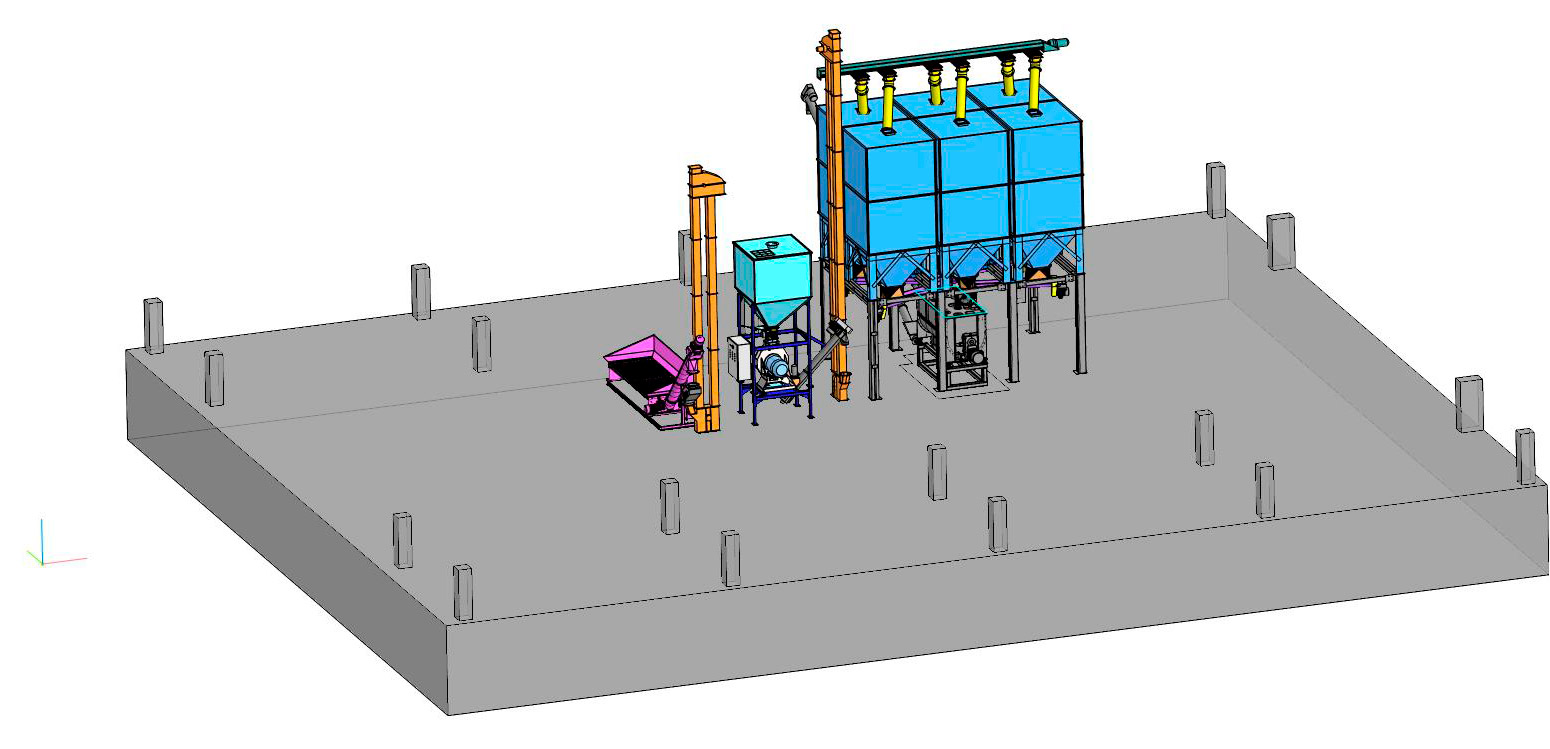

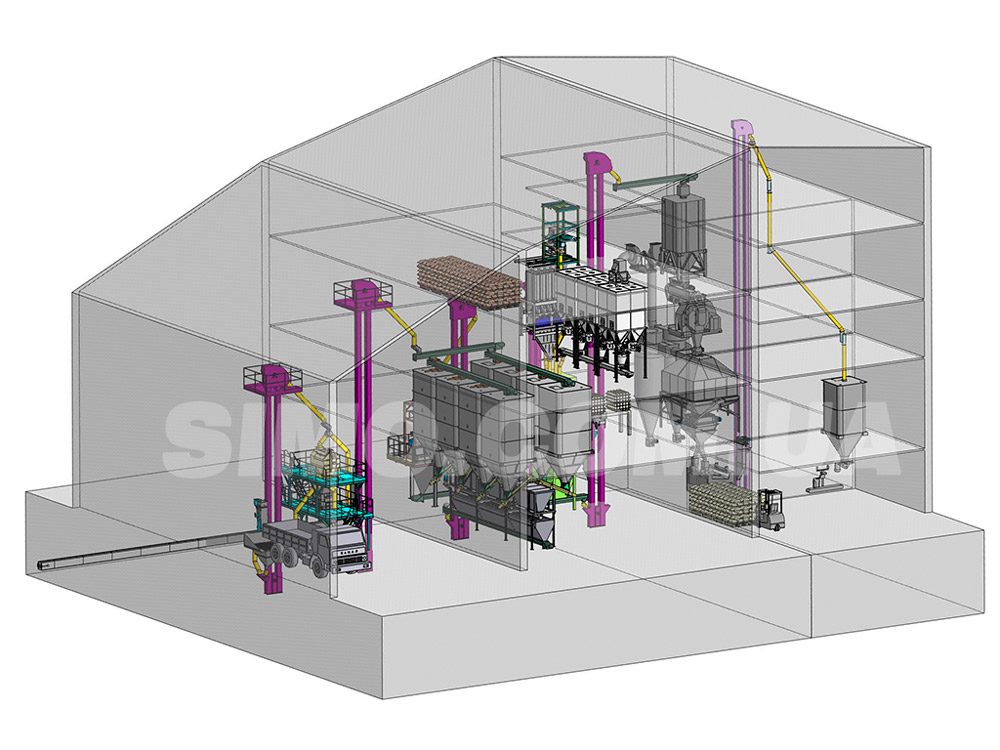

Module feedstuff mill ЛПК-3М is designed to to produce loose feed with productivity up to 3 t/h and to weighing and packing finished feed into bags of 20, 30 or 50 kg. Occupied area is 80 m2 (area dimensions (8 m x 10 m) including service area, but without place for intake bin and warehouse of finished product.

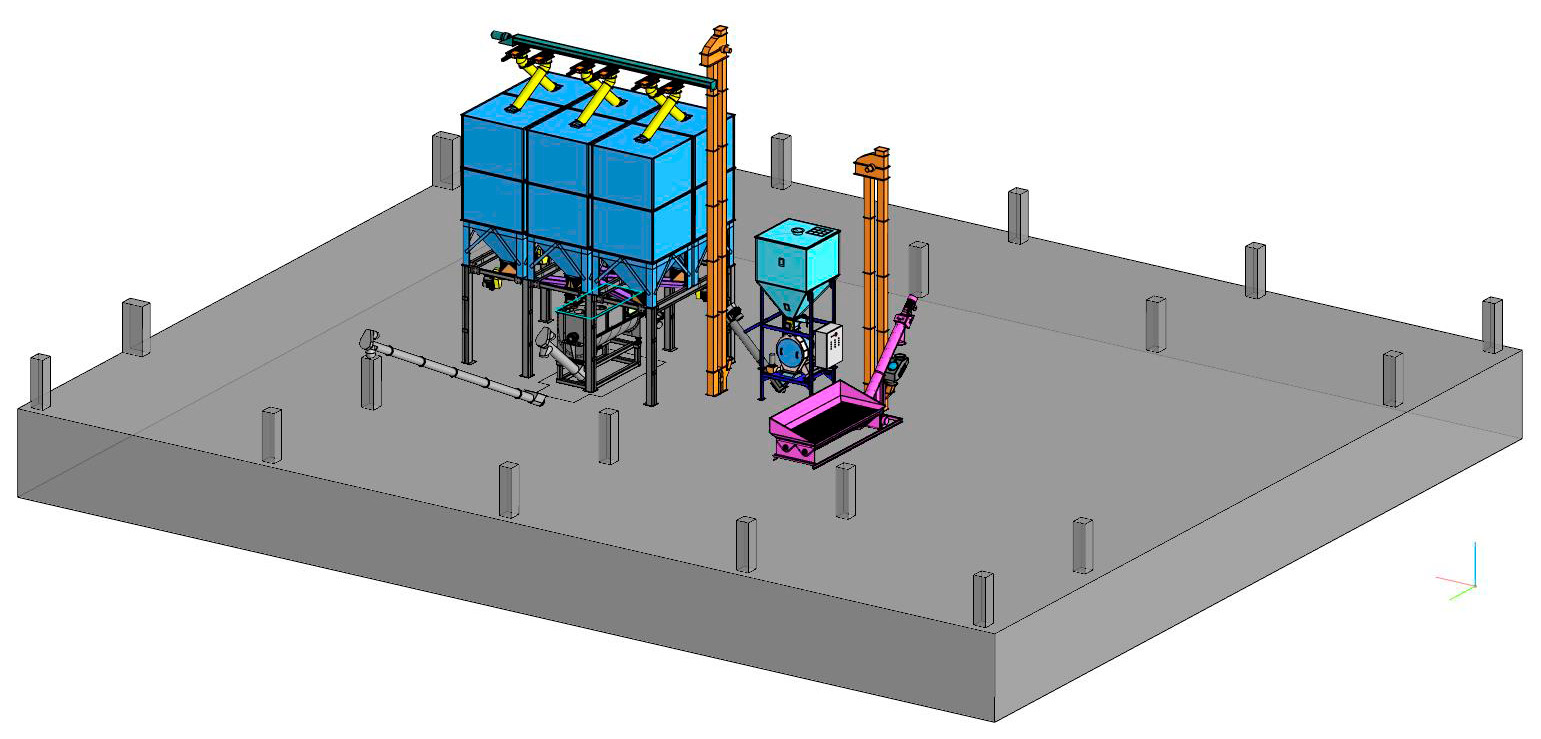

Module feedstuff mill can be delivered by four 40-feet containers OPEN TOP (12 000 (l) × 2 230 (b) × 2 380 (h)). It can be supplied as assembled modules provided with separately packed transport equipment (bucket elevators and augers), staircases, service areas with cable and wire products.

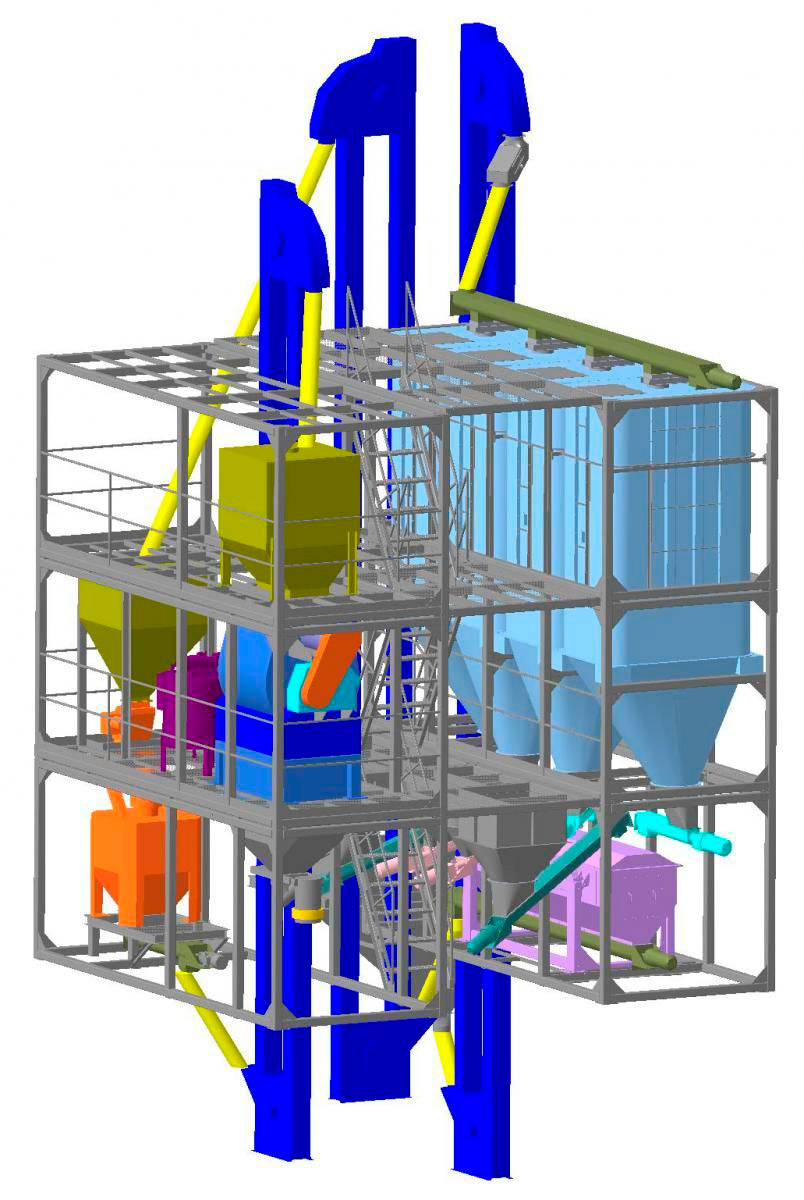

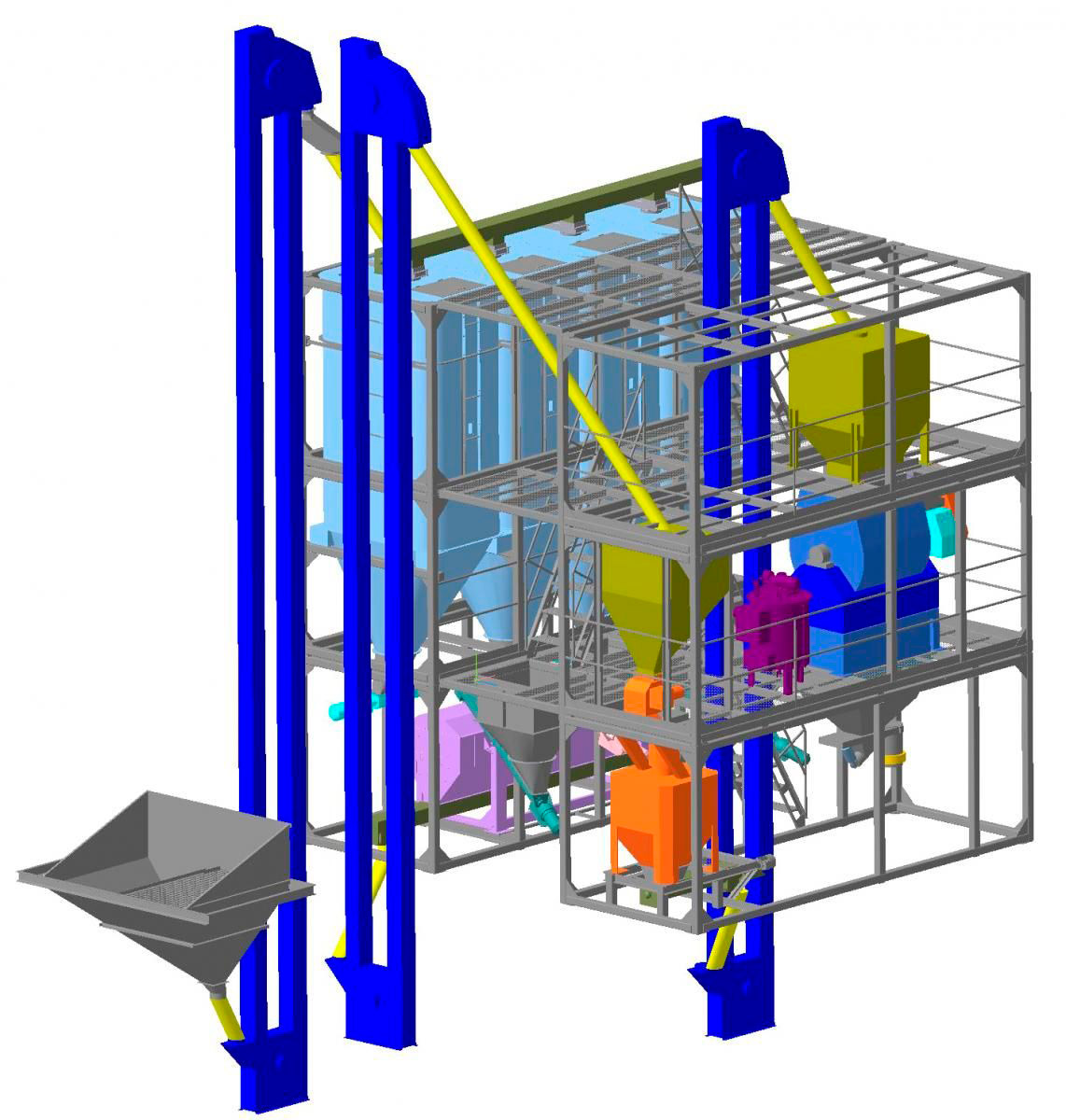

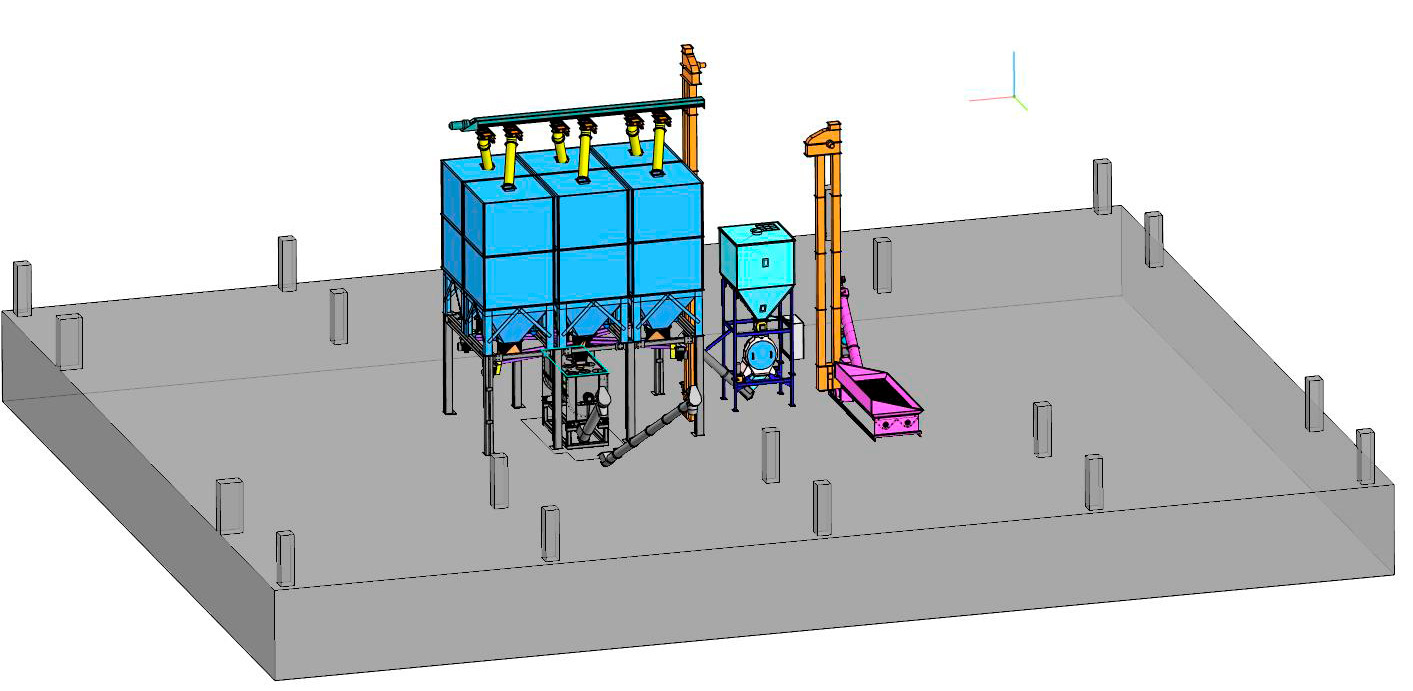

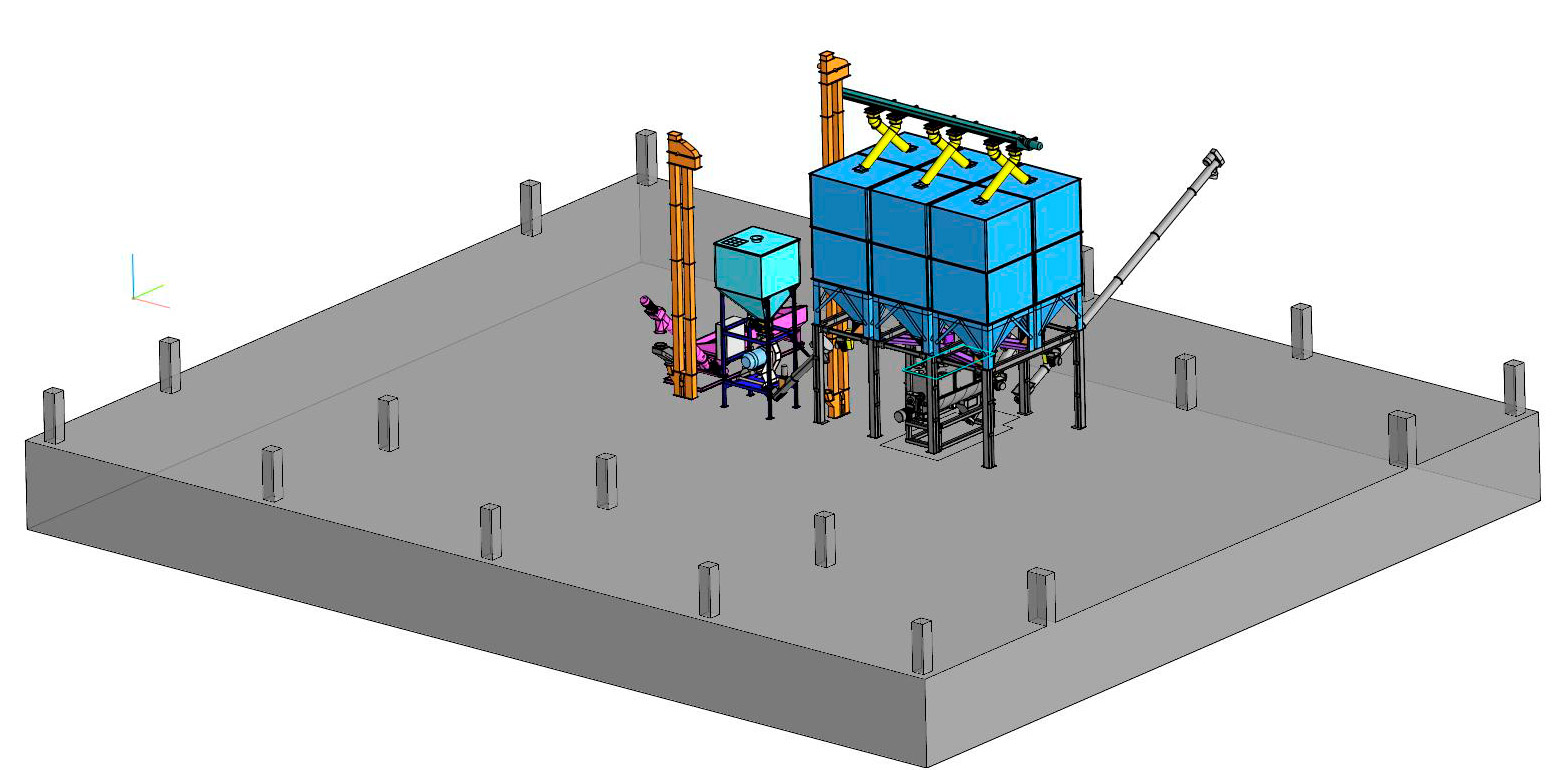

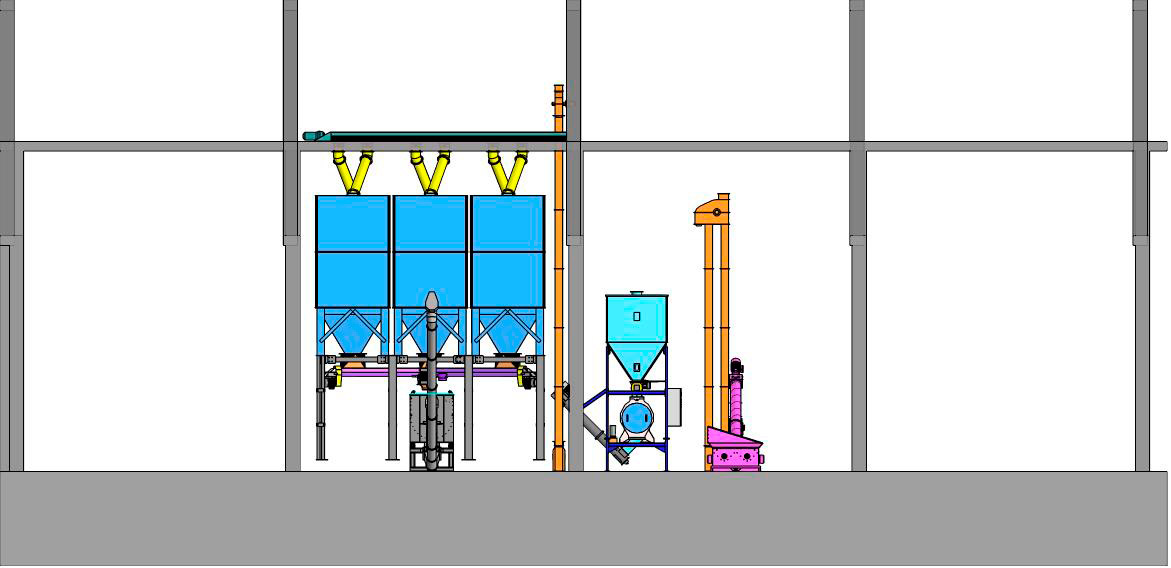

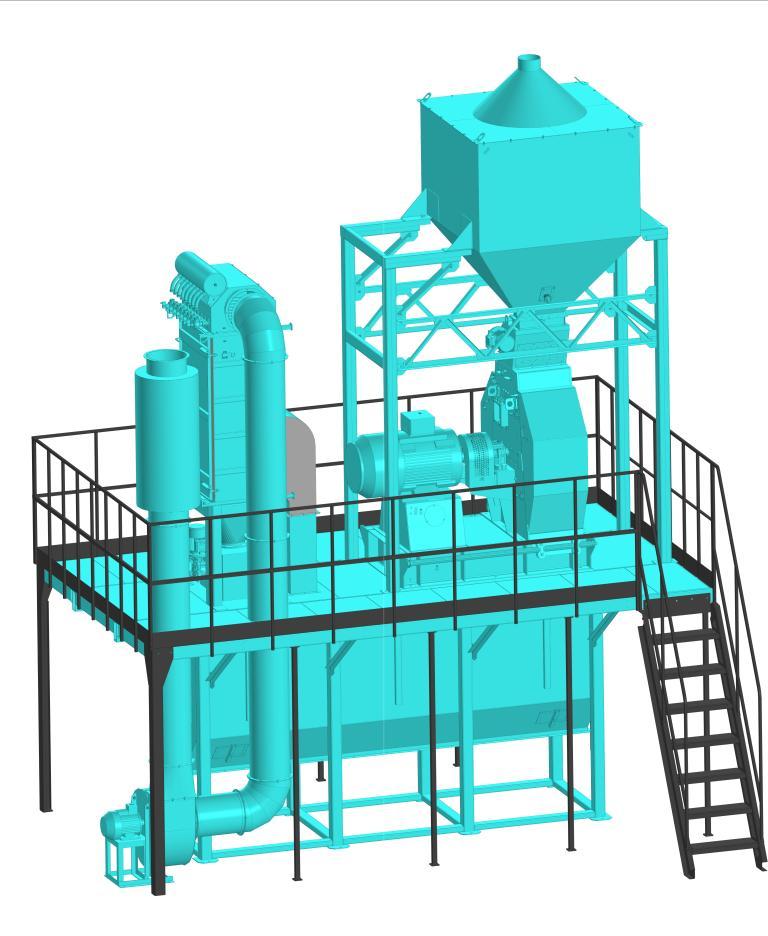

These modules are ready to be mounted with special technological equipment (7 pcs.), namely – hopper belt module, hoppers output module, module of scales, module of hopper over the mixer, module of mixer, grinding and packing module, operator's room

This technology needs 4 grain and schrot hoppers, augers with loading funnels for small batches of components hatch for manual additional loading of components (into the mixer).

Advantage of such kitting is good complete set and high assembly readiness. The modules are joined together by prepared places according to the wiring diagram. Then they joining with ready staircases, fences, service areas, bucket elevators, augers and cable wires. Checking the equipment switching and setting up the computer control system of the line takes place from the operator's room.

Module feedstuff mill includes equipment, which is often using at the large feedstuff plants and mills. This fact lets to produce feeds as per state quality standards. Particularly, Paddle mixer ЗСЛ-1000 can produce the feed with 95 % of homogeneity.

Some advantages of the Module feedstuff mill of SIC “AGRO-SIMO-MASHBUD” are:

- actually implemented modularity (as opposed to block layout);

- steel frame structure and that means all equipment is fastened on steel frames. It lets to avoid to capital construction costs and reduce the area for placement;

- it's completed with industry equipment for large feedstuff mills;

- 4 hoppers for raw product (30 m3 of volume) inside module;

- comfortable computer control system lets to manage all equipment independently and work round-the-clock for a week;

- the possibility of placement without stopping the existing production;

- transportation in standard ordinary containers and lorries by sea, road or railway (module length is 6 m);

- quick installation, because it just needs to combine ready-made modules;

- installation and commissioning takes 5-6 days (if the area for mill and place for intake bin and bucket elevator shoe are ready).

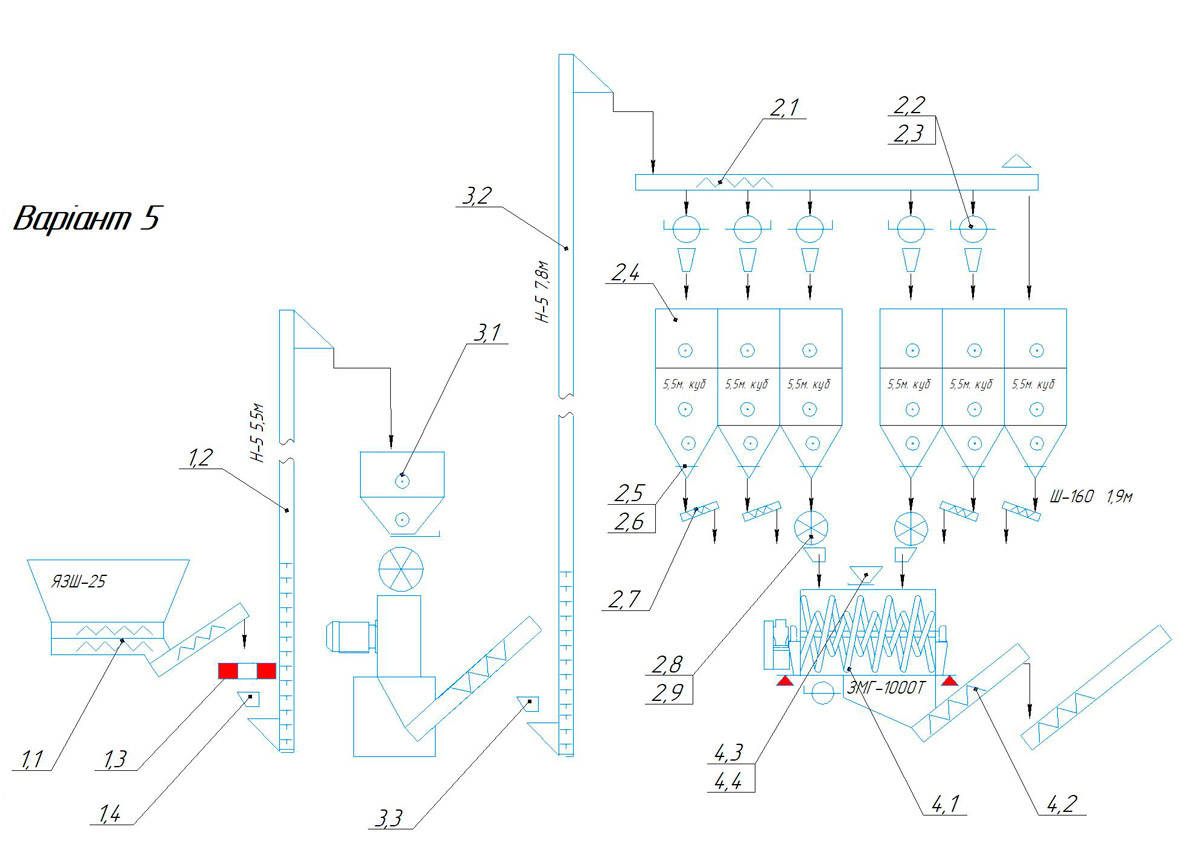

List of equipment for feedstuff processing stuff with 3 t/h of productivity:

| Pos. |

Marking |

Name |

Quantity |

kWt |

Total kWt |

| 1. Section for raw product input |

| 1,1 |

ЯЗШ-25.00.000 |

Screw intake bin |

1 |

4,4 |

4,4 |

| 1,2 |

Н-5 |

Bucket elevator Н-5,5 m, «Stroina» |

1 |

1,1 |

1,1 |

| 1,3 |

MZ-200 |

Magnetic gravity |

1 |

|

|

| 1,4 |

ПП-Н5-MZ |

Adapter |

1 |

|

|

| |

5,5 kWt |

| 2. Section for raw product dosing |

| 2,1 |

Ш-160; 5,0м |

Screw conveyor 1 input - 6 output, stake sensor; quill S4; STROINA ZG32-30 i=7.45 SMR 100L4 (189 RPM, 2,2 kWt) |

1 |

2,2 |

2,2 |

| 2,2 |

ПНЗ-200 |

Pneumatic gate valve |

5 |

|

|

| 2,3 |

К-200хД200х100 |

Adapter |

5 |

|

|

| 2,4 |

БС-1,5х1,5 |

Hopper, 2 belts (5,5 m3) |

6 |

|

|

| 2,5 |

ПБС-160х0 |

Adapter |

4 |

|

|

| 2,6 |

БС-1,5-Р6 |

Frame of dosing hoppers |

1 |

|

|

| 2,7 |

Ш-160; 1,9 м |

Screw dosing conveyor, chain drive |

4 |

1,1 |

4,4 |

| 2,8 |

ШЗХ-10С |

Dosing gate valve |

2 |

1,1 |

2,2 |

| 2,9 |

ПП-ШЗХ-10С-160 |

Adapter |

2 |

|

|

| |

8,8 kWt |

| 3. Section for raw product grinding |

| 3,1 |

ВПК-22.00.000 |

Components grinding section |

1 |

23,65 |

23,65 |

| 3,2 |

ПП-Н5-MZ |

Adapter |

1 |

|

|

| 3,3 |

Н-5 |

Bucket elevator Н-5; 7,8 m |

1 |

1,1 |

1,1 |

| |

24,75 kWt |

| 4. Section for mixing |

| 4,1 |

ЗМГ-1000Т |

Horizontal mixer (with stain gauges) |

1 |

5,5 |

5,5 |

| 4,2 |

МКУ-1,5.08.000 |

Screw conveyor |

1 |

1,1 |

1,1 |

| 4,3 |

МКУ-2.13.000 |

Funnel |

1 |

|

|

| 4,4 |

МКУ-1,5.11.000 |

Gate valve |

1 |

|

|

| |

45,65 kWt |