Purpose:

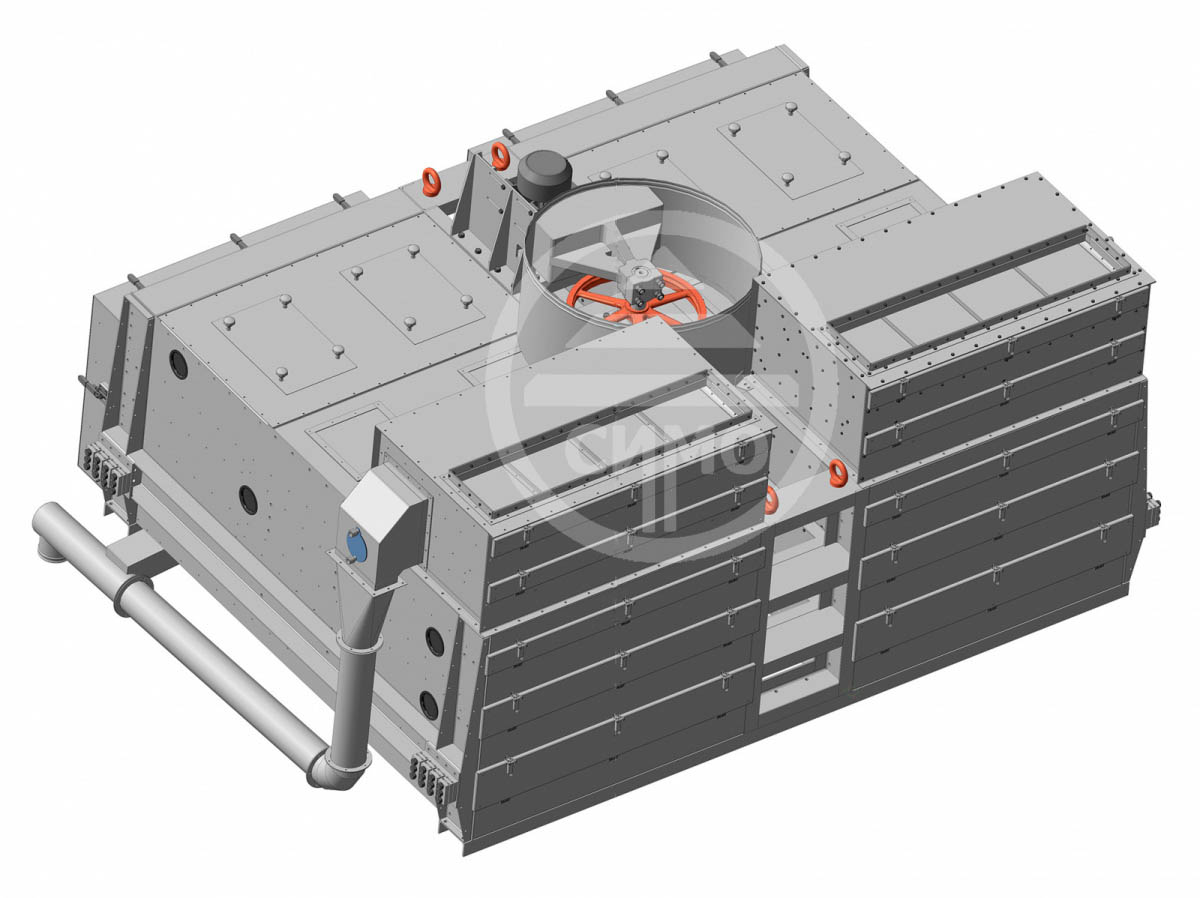

Seeds sunflower sifting machine ПНС-200 is designed for sieving of pre-cleaned seeds of sunflower alongside dividing oil kernel and husk during sunflower oil processing. Technical productivity of outlet product is 160 t/d minimum.

Specification:

| Name of indicators: |

ПНС-200 |

| 1. Technical productivity of finish product (outlet crushed seeds), min., t/day.: |

160 |

| 2. Oil (without wax) of outgoing husk over marketable, max., %: |

| - from sediment chambers of the blowing device |

1,0 * |

| - after control |

0,8 ** |

| 3. Content of husk in the kernel, max., % |

12 * |

| 4. Kernel in the husk, max., % |

1,1 * |

| 5. Nominal power, kWt |

7,0 |

| 6. Frequency of the plansifter rotation, с-1 |

3,31 *** |

| 7. Radius of rotation pattern, mm |

45 ... 50 |

| 8. Frequency of fan roller rotation, с-1 |

11,8 - 13,0 |

| 9. Airflow consumption, max., m3/h |

18 000 |

| 10. Occupied area in mounted condition, max., m2 |

9,2 |

| 11. Specific electricity consumption, max, kWt*h/t |

1,1 |

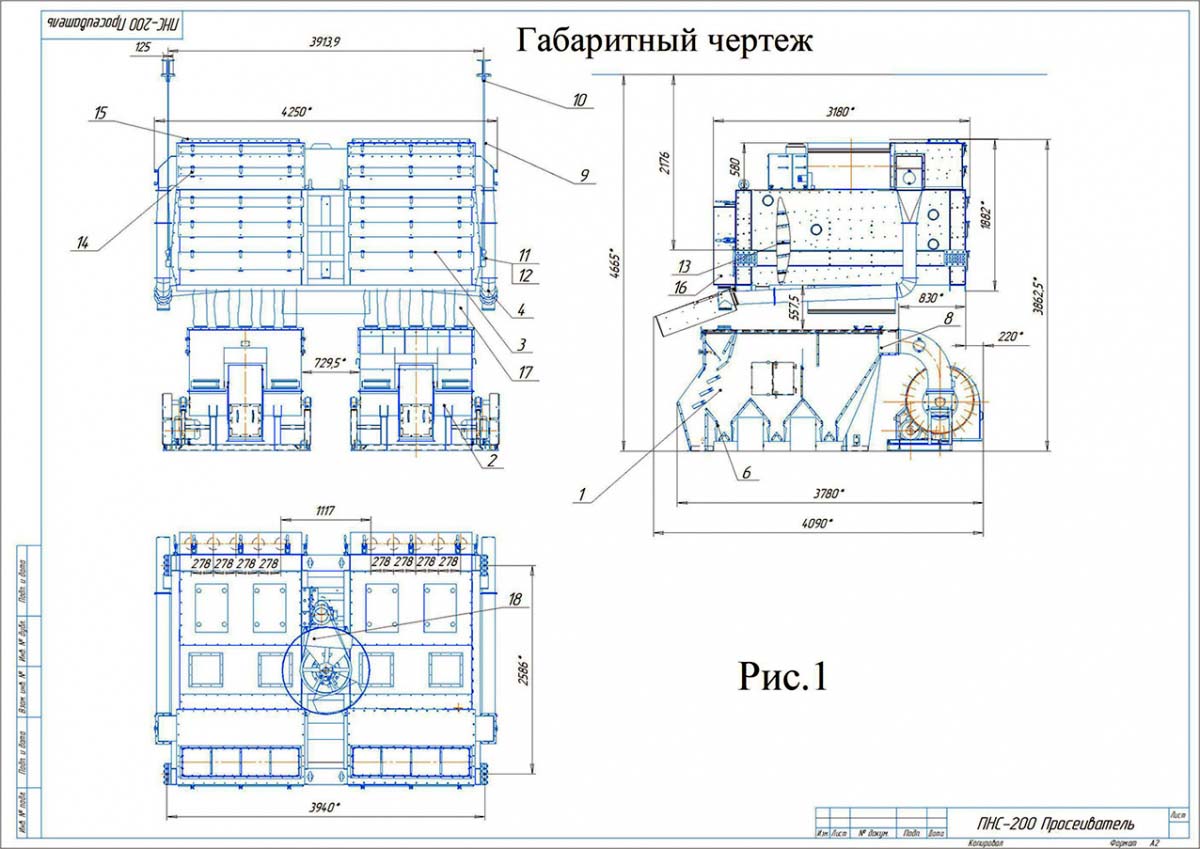

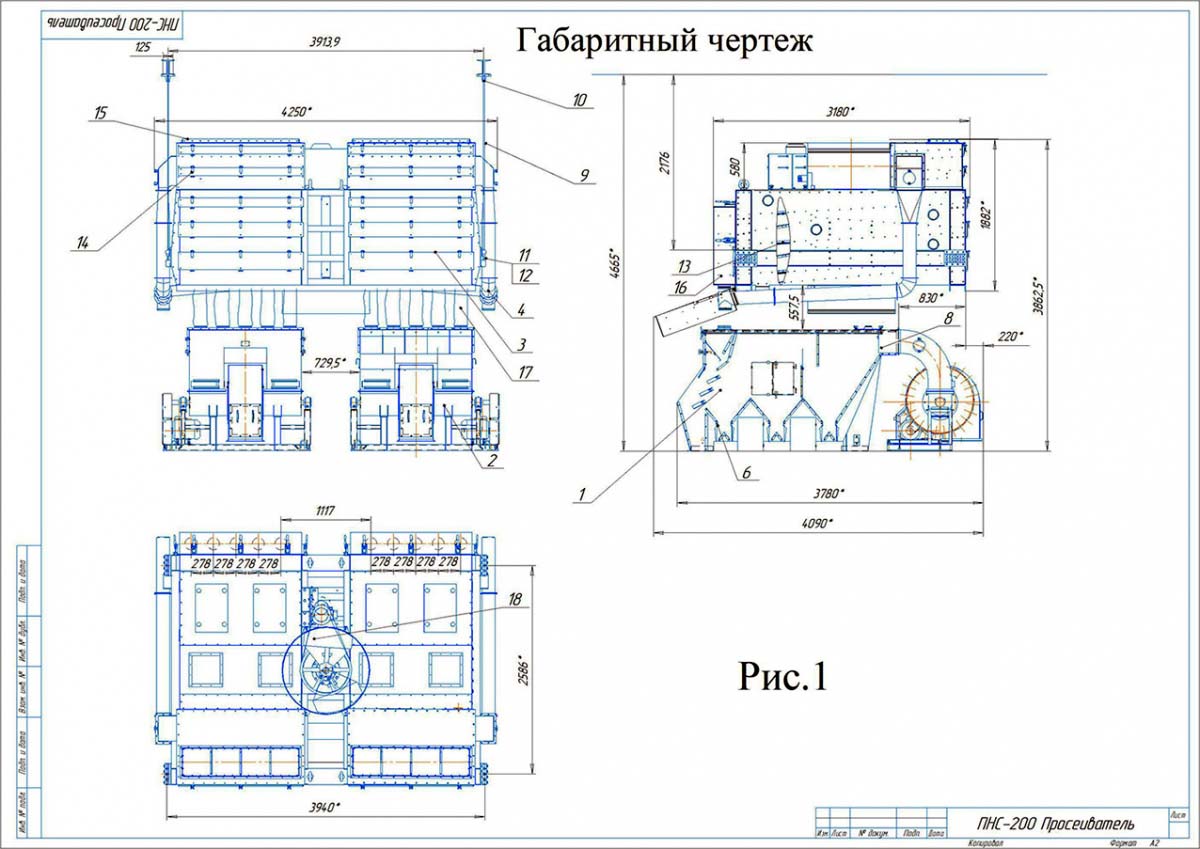

| 12. Dimensions, max., mm: |

| - length |

4 000 |

| - width |

4 250 |

| - height |

4 500 |

| 13. Weight, kg (max.) |

6 500 **** |

| 14. Due validity period without overhaul, years |

5 |

| 15. Total operating life, years |

8 |

Notes:

* These are indicators during crushing oil sunflower seeds with uncrushed parts up to 25 % and oil dust up to 10 %, and broken seeds up to 15 %. (When the machine is processing of sorted sunflower seeds, the absolute values of technological efficiency indicators should be improved (reduced) by 1.5 times).

** When using the machine for control of husk with oil content (without wax) no more than 1 %.

*** Depending on sunflower size, the frequency can be changed from 3,17 to 3,58 С-1. Needed frequency of plansifter rotations should be installed by method of selection of replacement motor pulley (Ø 126 mm, Ø 142 mm). Pulleys are supplied by special order. There is pulley Ø 132mm installed on the plansifter.

**** Without spare, removable and assembly parts.

Data comparison ПНС-200 and НВХ (Air fraction machine HBX):

- The same technological scheme of crushed product division and rotation frequency.

- The Sifting machine ПНС-200 has sieve area and weight twice as much.

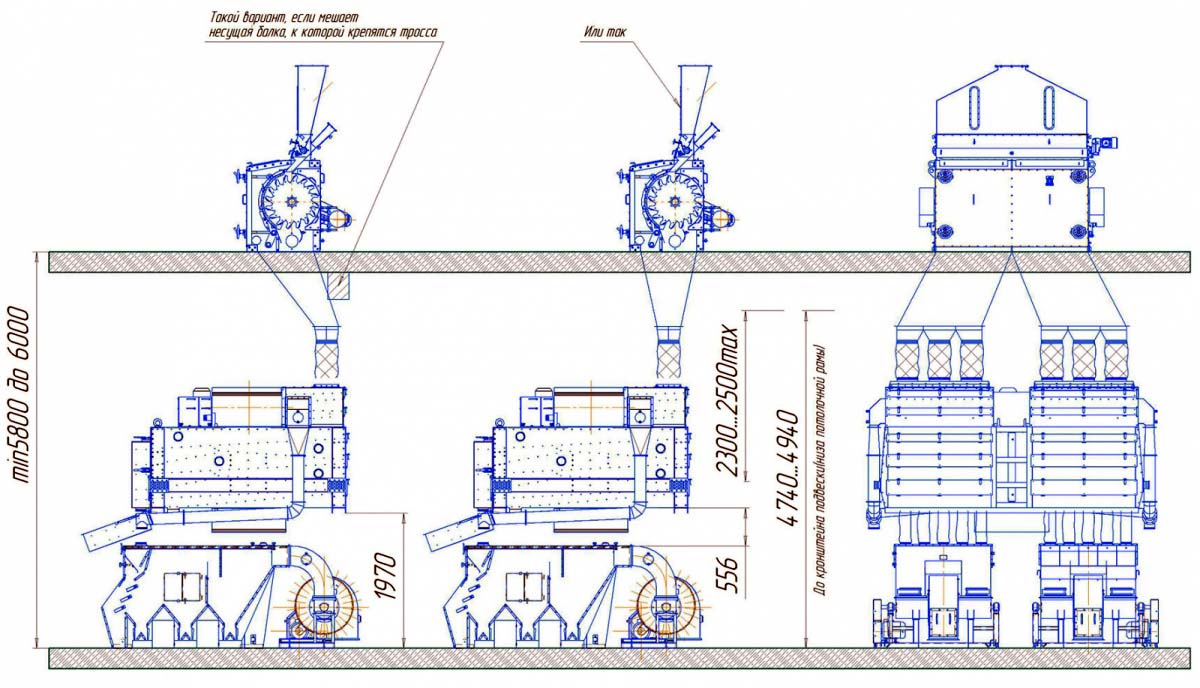

- The height of the floor became more (5 800 – 6 000 mm). Earlier it was 4 800 – 5 000 mm.

- The machine ПНС-200 placed on one floor (6 000 mm), while two needed machines SMA-203OIL placed two floors (12 000 mm). The machine ПНС-200 has better technological indicators and productivity.

- The machine ПНС-200 has better technological indicators and productivity:

- The sieve frame of this model (ПНС-200) doesn’t make in wood, it made in light metal (hollow rectangle construction);

- The ability to take out and maintain sieve frames from both sides;

- Collecting removable box is all-metal. It's easier to serve and repair.