Purpose:

Crushing centrifugal machine РЦ-200 is designed for sunflower crushing at oil industry.

The machine made according to 3rd category of State Standard (GOST 15150, climatic execution “У”) for domestic market and export to temperate countries. Concentrator should operate in working terms at the temperature from - 10 °С to + 40 °С. Relative humidity should be 80 % if average annual temperature is + 15 °С and atmosphere pressure is 650 - 800 mmHg (86,6 – 106,7 kPa).

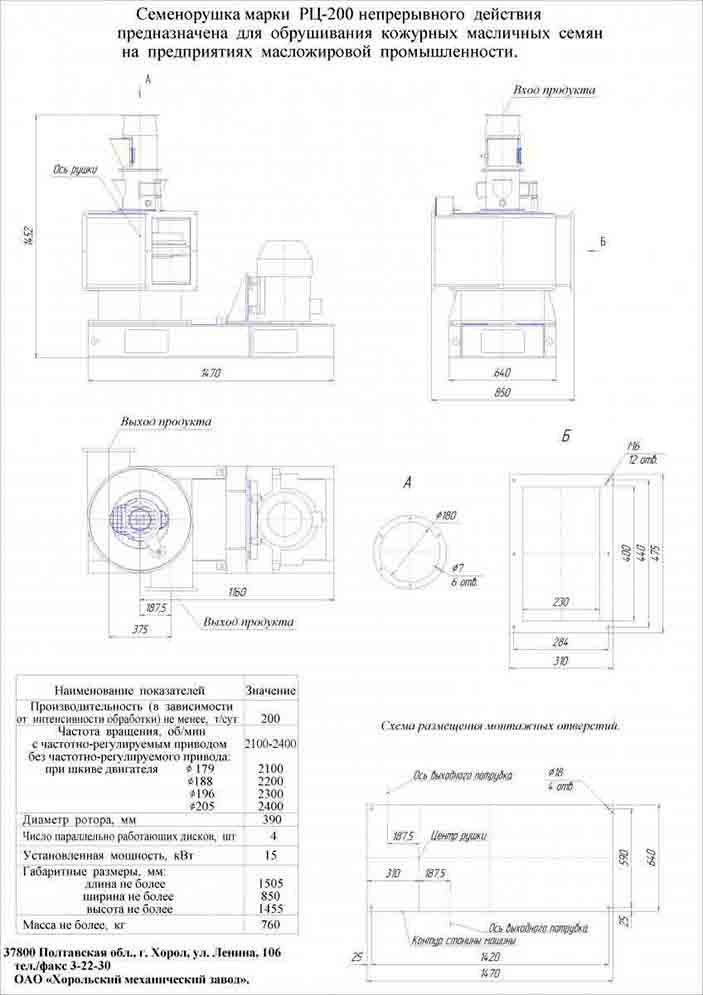

Specification:

| Name of indicators |

РЦ-200 |

| 1. Productivity of sunflower seeds processing, min, t/d |

200 |

| 2. Frequency rotor rotation, RPM: |

2100

2200

2300

2400 |

| 3. Rotor disk diameter, mm |

390 |

| 4. Number of parallel working disks, pcs. |

4 |

| 5. Number of radial channels in disk, pcs |

15 |

| 6. Installed capacity, kWt |

15 |

| 7. Dimensions, mm |

|

| - length |

1 550 |

| - width |

850 |

| - height |

1 450 |

| 8. Weight (without mounting and replacement parts and electric equipment), max., kg |

760 |

Design and operation:

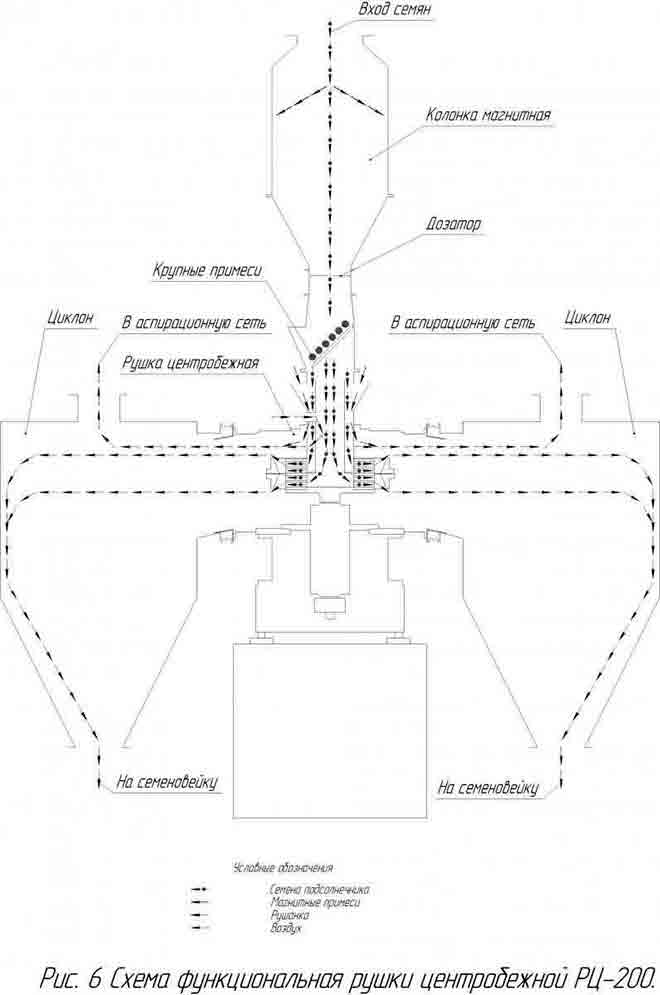

The machine (draw. 1 and 2) consists of body (1), mounted to the bed, the bed (2), switchboard (3), working disks (4), radial channels (5), ring deck (6). Collecting disks are rotor assembled on vertical roller (7). Roller with rotor rotates in the bearings (8). Two body nozzles (1) connected with two cyclones (10) which have outgoing traffic. Switchboard consists of cylindrical chamber (14) with safety grid (15), cylindrical nozzle (16), ring partition (17). The partition divides the upper working area of the rotor from the lower working area. Cylindrical nozzle has pipes (18) for suction air into the lower working area.

In the upper part of the chamber, there are holes for air suction into the upper working area. These holes covered by pockets (19).

For out the large impurities grid off, there is the hole across the grid (15). The hole covered sideways by swivel pocket (20) (drawing 4). Switchboard can be swiveled (outleted) to the side for quick access to the rotor body (Drawing 5).

The principle of operation is based on the method of single directional impact of seeds on the deck. More detail about the principle of operation:

Sunflower seeds continuous move into the safety grid. Then the product evenly distributed in a thin layer over the entire area of the inclined safety grid. After that, the product goes through safety grids and it helps for air suction.

The large uniform impurities roll off grid and collected in the pocket (20). Sunflower seeds go to the guide channels (5) of working disks of upper and lower working areas. They go there combined with suction air through covered pipes and holes (18). The seeds go from radial channels (5) to the ring deck (6).