Purpose:

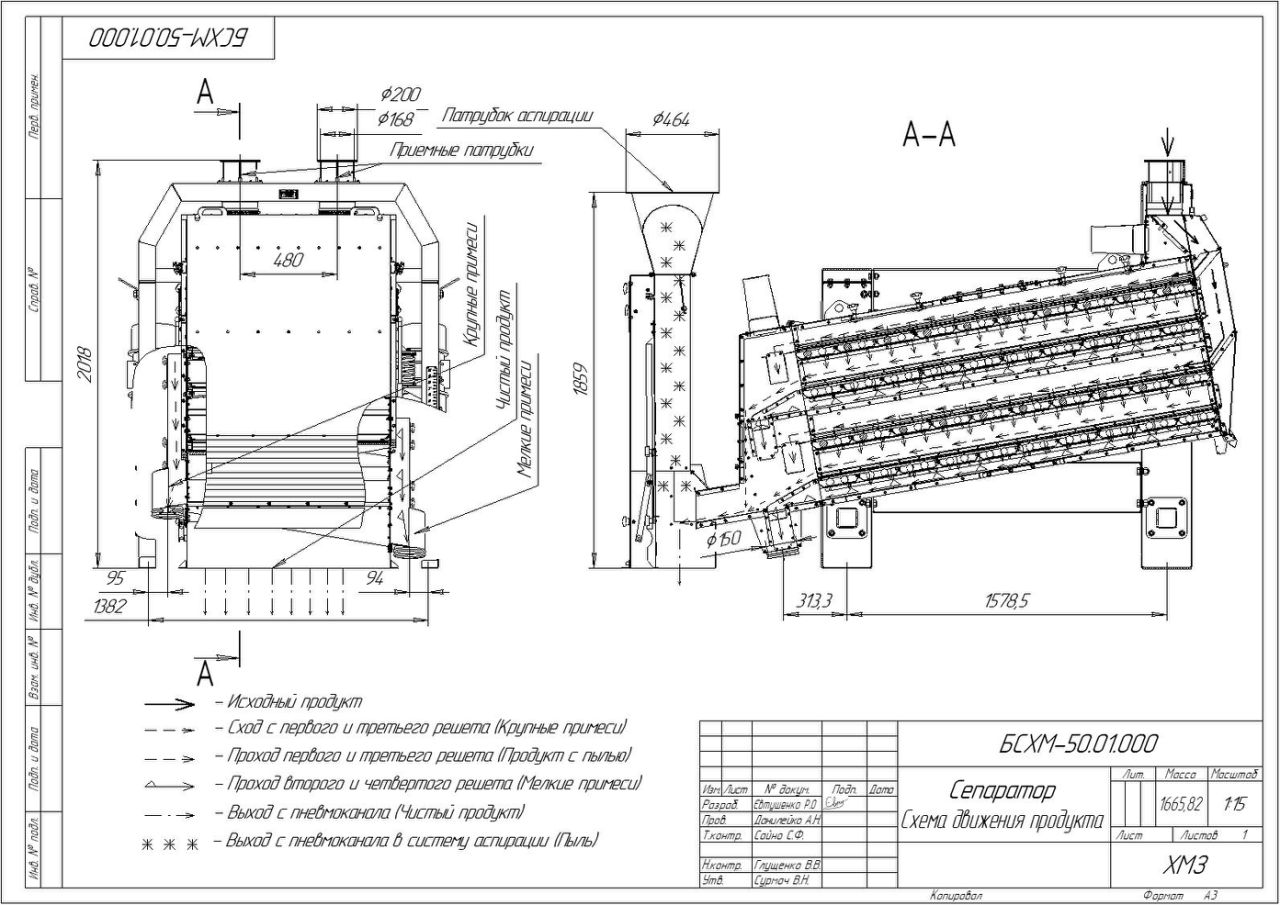

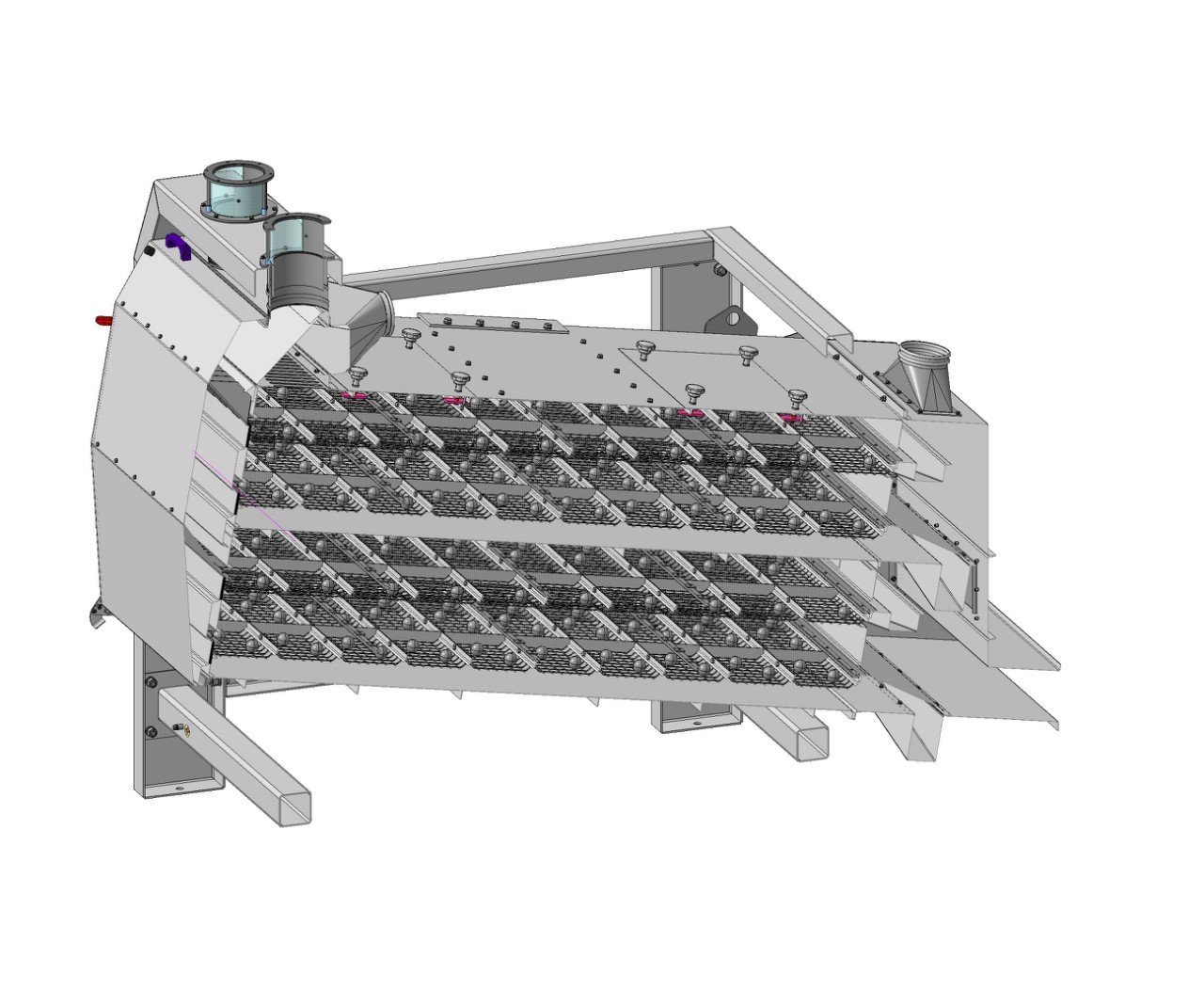

This machine designed for cleaning grain (wheat, barley, oat, rye etc.) from the impurities, different from it in width, thickness and aerodynamic properties. БСХМ brand separator line is very successful project of our designers. The machine also can divide the grain into fractions. Separators are installed as a part of technological schemes on the lines of post-harvest grain cleaning. It can be used in elevators and mills. This machine БСХМ-50 differs significantly from its predecessors in its characteristics and it designed to improve the capacity and quality of grain cleaning.

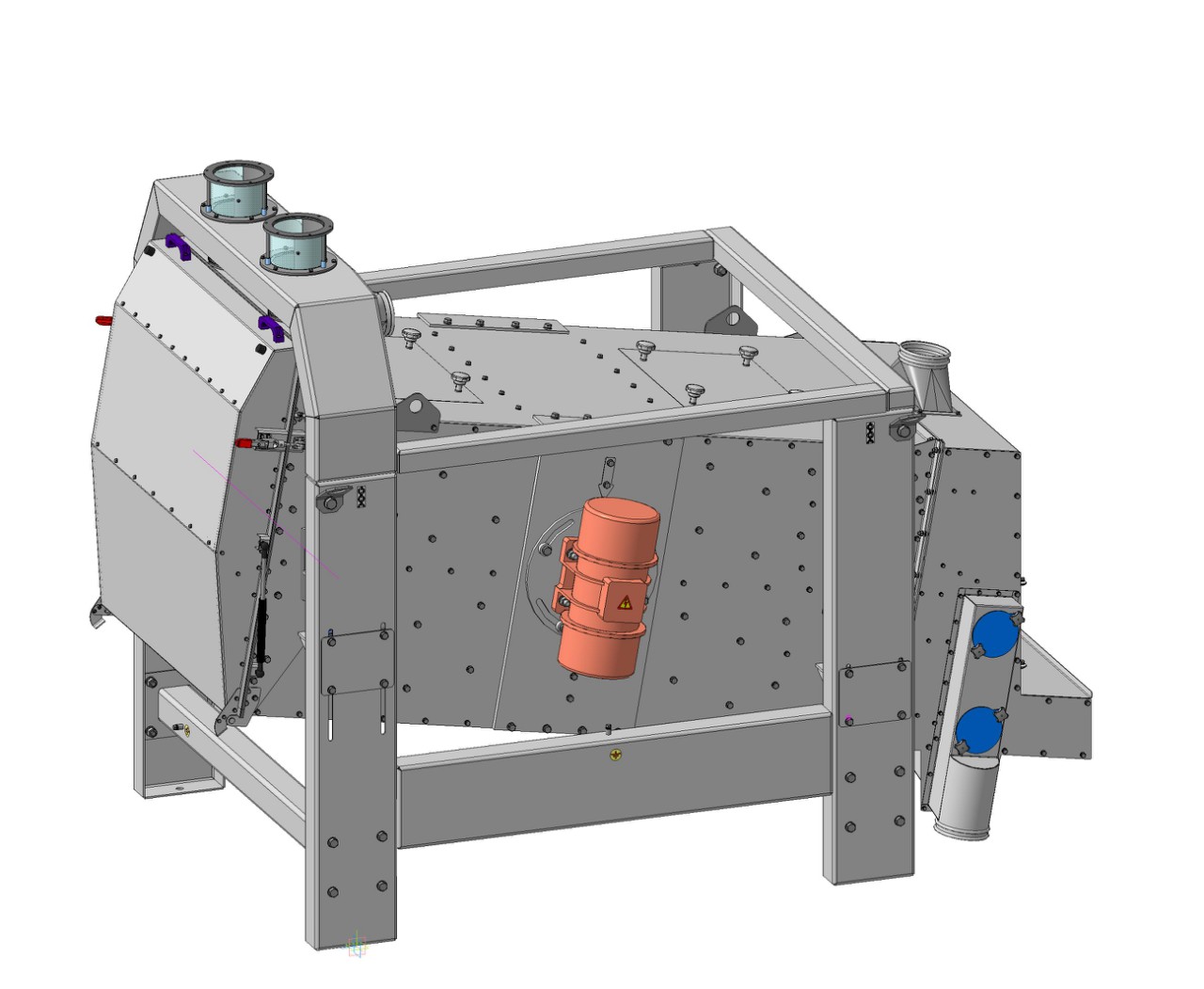

Operating vibrations are generated by two vibration motors with adjustable eccentric parts. This generation allows to control of operation mode (amplitude, direction and vibration frequency, change of an angle of the separator body). Due to the vertical component of the oscillations, there is relative motion of grain with flip. It more effective for continuous motion of flat particles when separated by thickness. This feature makes machines of this type the most effective in grain calibrating (sorting) as part of preparation lines of high-quality seed (raw materials), selecting the largest fraction for use in food, sorting granules after granulation and grinding.

Differences between БСХМ-50 and БСХМ-16:

- the area of sieves is twice as much (from 4 to 8 m2);

- quick change of sieves (without changing of sieve frames);

- scavenging while grain input in separator for partial selection of light impurities.

Specifications:

| Parameter |

БСХМ-50 |

| 1. Technical productivity for wheat and rye (2-3% clogging and 15% max of humidity), t/h: |

|

| - Preliminary cleaning, (elevator mode) |

80 |

| - Finish cleaning, (flour mill mode) |

30 |

| 2. Efficiency of cleaning: |

|

| - Pre-cleaning, %, min; |

25 |

| - Finish cleaning, %, min |

75 |

| 3. Sieves area (receiving and/ additional), m2 |

8 (4 / 4) |

| 4. nstalled capacity, kW, min |

0,75 * 2 = 1,5 |

| 5. Vibration amplitude (span) of machine body, mm |

5 ÷ 5,5 |

| 6. Anger of body, degrees: |

|

| - For pre-cleaning |

10 |

| - For finish cleaning |

6 |

| 7. Anger of vibrator, degrees: |

|

| - For pre-cleaning |

25 |

| - For finish cleaning |

20 |

| 8. Airflow rate for aspiration, m3/h, max |

5 600 |

| 9. Dimensions (with pneumatic channel), mm: |

|

| - Length |

2 700 |

| - Width |

1 690 |

| - Height |

2 100 |

| 10. Total weight of separator, kg, max, including: |

1 400 |

| - Separator weight |

1 250 |

| - Pneumatic channel weight |

150 |

![0-02-04-deb89b10e6c753aba8890e7197611571fe392fcc294b9fbcbb7a99d529c1349e_8213a63e[1].jpg](/en//assets/gallery/12/1520.jpg)