Purpose:

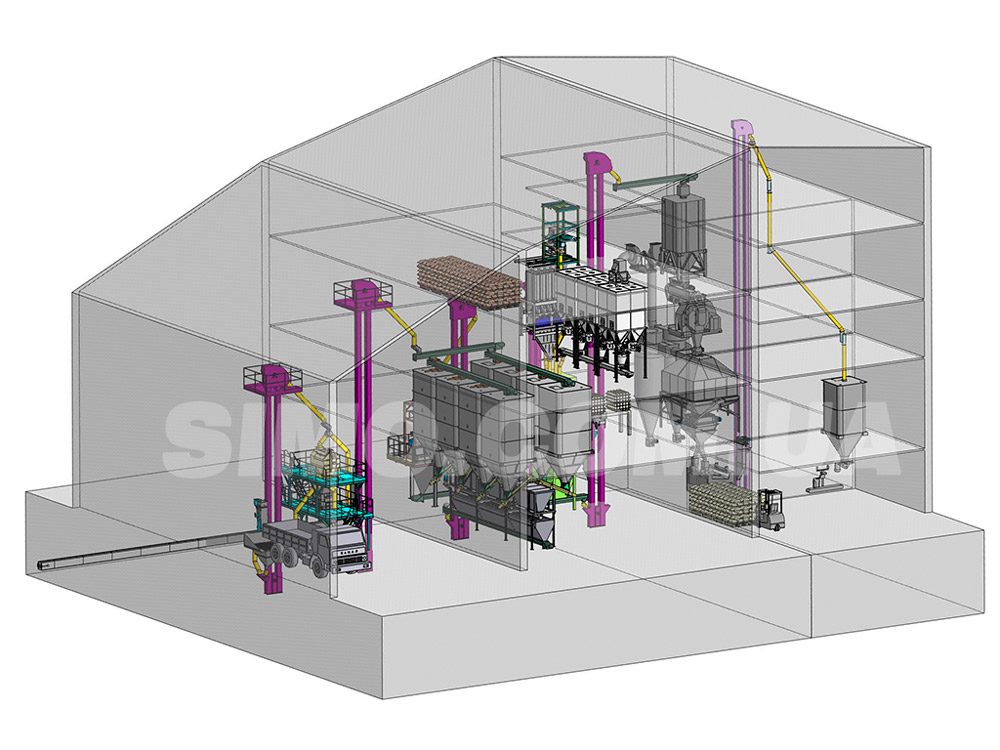

Feedstuff mill УПК-2-4 is designed for crumbly feedstuff processing as per the specified recipe for all types of poultry, pigs and cattle.

Features of the Feedstuff mill УПК-2-4:

- compactness;

- minimal human factor in operation;

- high exactness and automatic dosing of 6 basic components;

- high productivity.

The Feedstuff mill with productivity up to 2 t/h with component dosing automatic unit and finish product unload unit. The machine based on the time-proven horizontal counter-current Mini feed plant МКУ-3, which provides uniformity of mixing 95-97% (depending on the specified recipe).

Specification:

| Technical characteristics |

УПК-2-4 |

| 1. Dosing |

Weighing |

| 2. Productivity, up to 1 t/h (when wheat is grinded with humidity of up to 14%, with by volume weight of 0,7 t/m3): |

|

| - up to size class 4 (sieve Ø 6 mm) |

2,0 |

| - up to size class 3 (sieve Ø 5 mm) |

1,2 |

| - up to size class 2 (sieve Ø 3 mm) |

0,9 |

| 3. Technical characteristics of the mixer: |

|

| - Degree of mixing uniformity, % |

95 - 97 |

| - Technical capacity, kg/cycle |

450 ÷ 530 |

| - Volume (capacity), m3, max. |

1,0 |

| - Cycle (period) of mixing, min. |

4 - 5 |

| - Unloading time /depending on productivity of unloading mechanism/, sec. |

100 ÷ 150 |

| 4. Power consumption, kW |

up to 30 |

| 5. Accuracy of component dosing, kg |

1 |

| 6. Number of main components |

4+ |

| 7. Hopper volume, m33 |

3+ |

Comparing of Mini feed plant МКУ and Feedstuff mill УПК-2-4:

The operator should load the recipe components consistently in the Mini feed plant МКУ through pneumatic feeder (and Hammer mill), focusing on the sound signal of the automatic control system. In this case, the hopper is loaded for 1 mixing (portion) of the component.

Regarding the Feedstuff mill УПК-2-4, the components should be crushed before to be filled in hopper (4-6 hoppers). Then the automatic system use these components to mix on the recipe for several portions. Operator only should control the hoppers to be filled in by components (they shouldn't be empty). He can do it due to side window or level sensors. The best advantages of the Feedstuff mill УПК-2-4 are minimal human factor, maximum accuracy and automatic dosing of components.

Advantages of this machine compared to classic automated lines:

- Compact design;

- Minimal mechanisms;

- Comparatively higher reliability;

- It's easy to clear;

- Absent of the preliminary pits;

- It is possible to modernise the line at any time by increasing the number of hoppers and their size;

- More economical operation of the machine work and, as a result, fewer number of starts and periods of operation without product.

Power consumption of this Feedstuff mill is up to 30 kW/h.