Purpose:

Discrete Dosing scales ДВС-301-10-1 is designed for the weighing and dosing of bulk and granule product to the bags. The machine also indicates on the digital display of the weight of the dosed product and, cumulatively, the total number of doses.

Specifications:

| Parameter |

ДВС-301-10-1 |

| 1. Limit of dosing, kg |

|

| - with small neck |

5 - 10 |

| - with big neck |

15 - 20 |

| 2. Productivity, bags/h |

Up to 360 |

| 3. Measurement resolution, kg |

0,005 |

| 4. Permissible dose error, %, max. |

0,2 |

| 6. Managing Dosing scales |

Electric pneumatic |

| 7. Nominal compressed air pressure, MPa |

0,4 ± 0,04 |

| 8. Air flow consumption, m3/hour |

0,5 |

| 9. Power consumption, VА, max. |

25 |

| 10. Temperature mode of operation |

- 10 … + 45 ºС |

| 11. Degree of protection against dust and water entering: |

|

| - weighing device |

IP 54 |

| - weighing processor ПВ — 310 |

IP 65 |

| 12. Weigh (mass) with big neck, net, kg, max. |

122 |

| 13. Weigh (mass) with small neck, net, kg, max. |

15,5 |

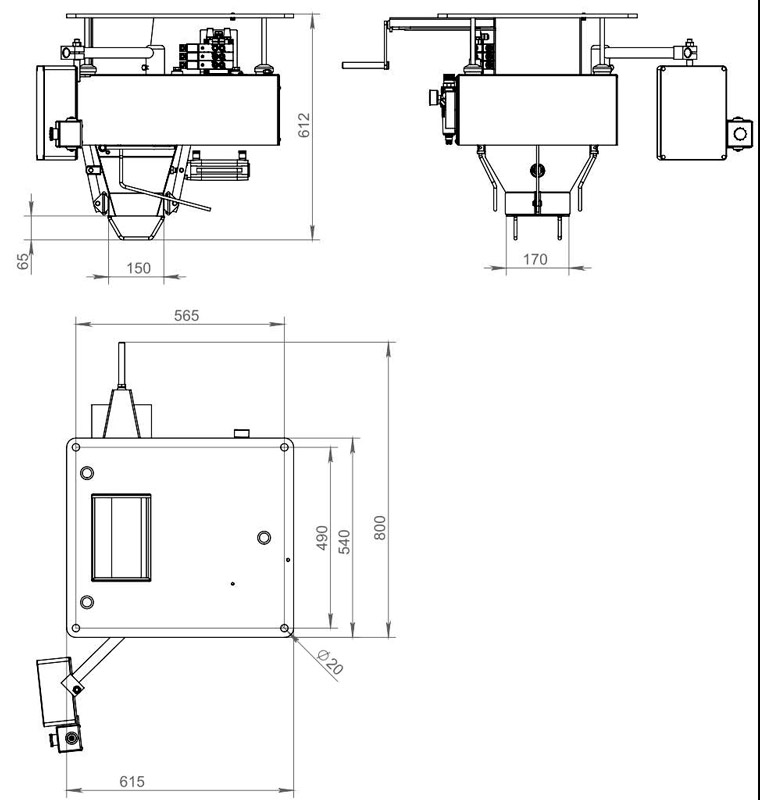

| 14. Dimensions, mm, length х width х height |

615 х 800 х 612 |

Design:

Functions:

- Exactly dosing of the product;

- Automatic control of weighing and dosing;

- Dose (bag) weight indication;

- Indication of the number of bags per shift, per day, since the start of production;

- Connection to a computer.

Installing of the Dosing scales:

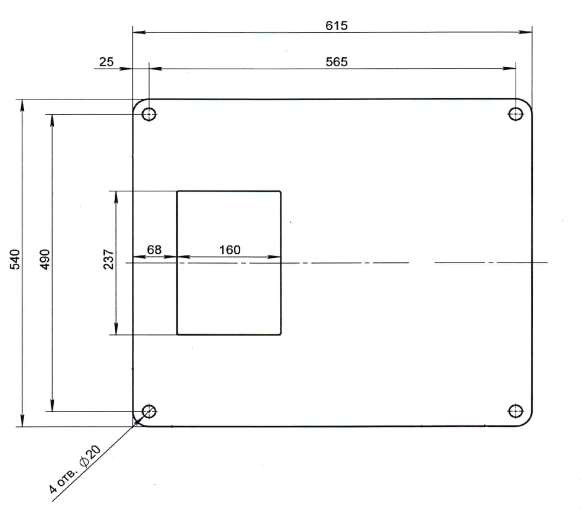

The dosing scales is hanged to the supply hopper with 4 bolt connections using an adapter plate. This plate is welded to the outlet hole of the hopper (you can see the draw of the adapter plate in attachment).

The height of the machine should be comfortable for operator work, so it should be 1 155 - 1 200 mm.

Principle of operation:

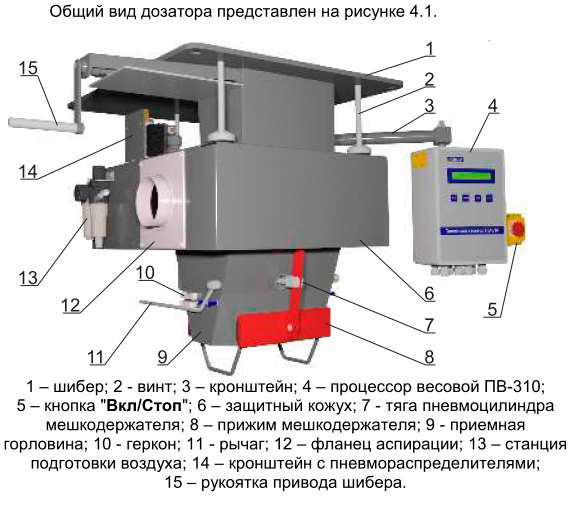

The operator puts the bag on the weighing neck. The bag is automatically fastened with a pneumatic clamp. The product leaves supply hopper for the Dosing scales by gravity. Afterwards, the weighing processor ПВ-310 let they know that gate valve can be opened. The dosing process “Roughly” starts. When the weight reaches 3 kg (if the dosage is 5 kg), the dosing scales switch to "Exactly" dosing mode and fills the remaining 2 kg more slowly and closes the gate valve of the product supply. When the weight reaches dose of 3 kg, the weighing processor instructs to fully closing of the gate valve. The product flow stops. The pneumatic clamp automatically releases the neck of the bag. The bag goes to the belt conveyor and moves for sewing.

The weighing processor ПВ-310 fully manages dosing (weighing) process.

Advantages:

- high dosing accuracy, fast operation;

- the usage of a highly reliable pneumatic drive (Camozzi, Festo);

- easy to install, set up and operate;

- technological viewing window for dosing scales service;

- quick adjustment of the dosing mode;

- reliable service and technical support.