Purpose:

Hopper automatic scales are designed for weighing and accounting of bulk products.

We offer the Hopper automatic scales for products accounting without stopping of technological process (flow system). Hopper scales ВБА with valves electric drive are so good to be used at elevators and grain terminals.

The scales can be completed with dust proof covers (look at the photo below).

The basic functions of the Scales ВБА-1100-Э-300:

- accounting of bulk products (flow system);

- the ability to set the amount of shipped material;

- sensor of portion weight;

- automatic control of dosing process;

- maintenance of scale productivity;

- sensor of total result for working shift/day etc.;

- data transfer to a computer and networking.

Specifications:

| Characteristics |

ВБА-1100-Э-300 |

| 1. Productivity (for wheat), m3/h |

up to 300 |

| 2. Working volume of weighing hopper, m3 |

1,1 |

| 3. Permissible weighing error, % |

0,2 |

| 4. Discreteness of accounting (dd) and value of division check (е), kg |

0,2 |

| 5. Communication interface |

RS485/RS232, ModBus |

| 6. Exploitation terms: |

|

| - air temperature, оС |

from - 25 to +50 |

| - relative humidity at 35оС, % |

up to 95 |

| 7. Motor supply voltage of electric drive, V |

380 |

| 8. Power consumption, kWt, max |

2,2 |

| 9. Scale weight, kg |

1 000 |

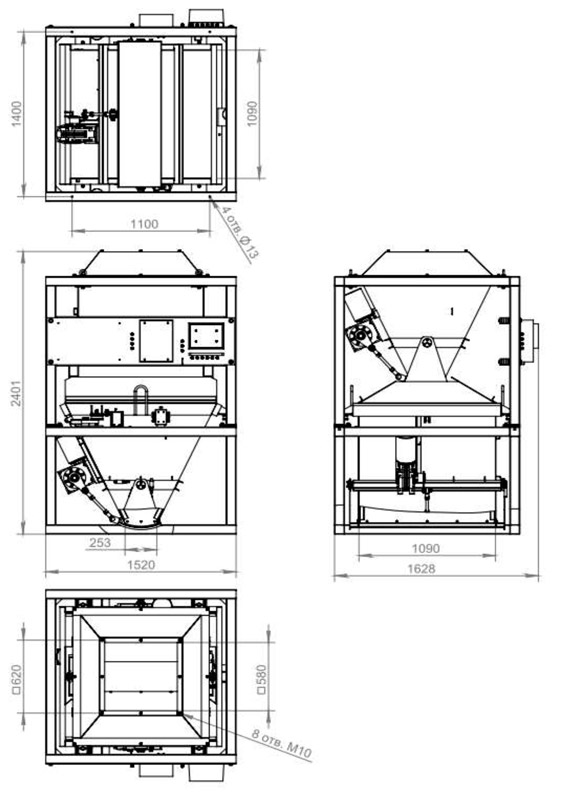

| 10. Dimensions, L/W/H, mm |

1700 х 1600 х 2400 |

Design and work:

Hopper automatic scales consist of receiving upper hopper and weighing hopper. The upper hopper is mounted on the frame. The second hopper fastened by the stain gauges. The valves of the upper and lower hoppers move due to electric drives. The scales are controlled by the weight processor ПВ-310. The processor processes of the stain gauges signals, controls the electric drive for opening and closing the valves of the weighing hopper. It also show the value of the mass of the material in the weighing hopper, portion weight, the cumulative result of the material passed through the hopper and other current parameters of the scales. It must be shown by the weighing process indicator.

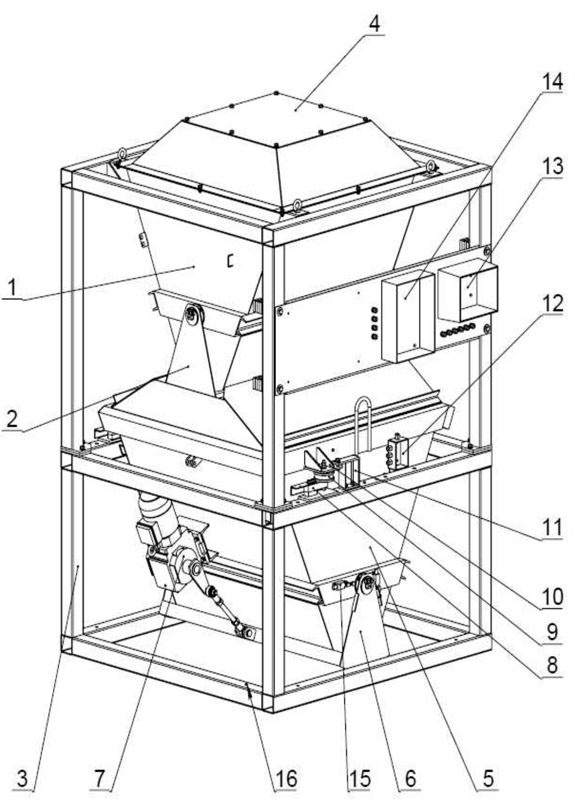

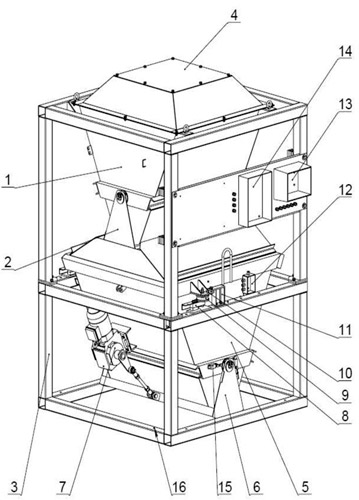

Hopper scales ВБА include the following constituent parts:

- Device of materials feed (УПМ), which consists of receiving hopper (1), gate valve (2) (it has two position: “opened” and “closed” owing to gearbox). The receiving hopper installed on the frame (3) with cover (4). The customer should make the hole in the cover for docking with the loading device;

- Receiving device (ГПУ) consists of weighing hopper (5) with gate valve (6). The gate valve has two position: “opened” and “closed” owing to gearbox (7). The hopper is leaned on weighing sensors (8) due to three feet (10) and absorbers (9). The weighing sensors are on the frame (3);

- Electronic weighing measuring device (УВЭ), it includes three strain gages (8), connection box (12) and weighing sensor ПВ-310(14);

- Electromechanical system, which consists of two gearboxes (7), control cabinet (13) and limit switches (15);

- Automatic control system (САУ), which provides execution of the monitoring and control algorithm using the elements of the weighing device and the electromechanical system.

All of above components are installed on the frame (3). There are special bolts in the upper part of the frame, and there are removable brackets (11) in the middle of the frame. These brackets are designed for upper hopper fixing while it is transported. There are grounding bolt (16) and holes for structure fastening in the lower part of the frame.

Weighing processor ПВ-310

Weighing processor is installed in the metal box (you can see it on photo) for dust protection and protection from unauthorized access to the electronic unit.

Weighing processor ПВ-310 has been designed for measuring and indication (on digital display) of weighs currency productivity and the value of the mass of weighed materials on a cumulative basis during technological operations. It also needed for remote transfer of:

- running total - to an external pulse counter;

- data to external device (PC or display) by interface RS-485.

Weighing processor ПВ-310 lets the machine stop the material supply process in “pause” mode and then to continue!

According to customer requirements, the Hopper automatic scales ВБА-1100 could completed with external display ТВ-330-16.

The display absolutely copies work of weighing processor ПВ-310. The display connects with the processor and lets to do control on distance 1 200 m. The display has interface for connecting with PC with standard protocol RS-485. The display is in operator room.

The algorithm of the scales ВБА-1100-Э-300

When you press the button “START”, the gearbox sets the gate valve (2) in position “opened” on the weighing processor. It provides material supply into the weighing hopper (5). By the way, the mass of the material is continuously controlled by the processor ПВ-310. When the target weight is reached, by processor command, the gearbox sets the gate valve in position “closed”. The weight of the filled hopper is measured (gross weight). Afterwards the gearbox (7) sets the gate valve (6) in position “opened” and the material starts to unload. At the end of unloading, the processor measures the mass of the packing.

The net weight of the weighed material and the progressive total of the material passed through the scales are calculated and displayed. Then the gate valve become in position “closed”, and the cycle of weighing is repeating.

The composition of the equipment set:

- the frame of the hopper scales;

- weighing hopper with section gate valve;

- receiving hopper with section gate valve;

- complete set of the receiving units;

- weighing processor ПВ-310 -1 pcs;

- a cabinet with a set of electrical equipment;

- electric drive of the gate valves;

- dust covers;

- set of operational documentation.