02.11.2023

In modern cereal mills, when producing 150 tonnes of buckwheat groats, approximately 35 tonnes of buckwheat husk is produced. We would like to take your attention on so-called "waste material". It might not actually be waste at all. Technologists appreciate the buckwheat husk. Therefore, the development of a buckwheat mill always takes into account the possibility of proper using of the husks.

1. Buckwheat husk as an eco-fuel

Well, don't hurry up to utilize the husk as a waste! The husk actually has a fairly high heating value. This fact equates it with wood briquettes. Thus, steam boilers designed to operate on buckwheat husk as fuel are included in the equipment of the cereal processing mills. These boilers produce saturated steam for technological and domestic needs of enterprises and mills. Heating capacity of husk is 1,5 times higher compared to gas. And also the use of husk as fuel leads to a significant reduction in the cost of finished products. The economic reasonability is clear. Because this is the type of fuel that does not require expenditures on extraction and logistics. Moreover, fuel supplies are replenished immediately locally and as long as the production facility for processing buckwheat grain into groats is operating.

2. Fertiliser and animal feed

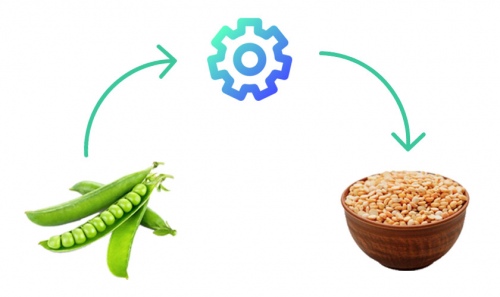

In agriculture, buckwheat husk is also used as fertiliser and feed additives. However, it should be realised that the feed properties of buckwheat husk should be improved by special treatment before it is used in mixed fodder. The fact is that buckwheat husk contains up to 50 % fibre, 3,2 % raw protein, 5,6 % fat, more than 0,3 % sugar, 9 - 10 % ash, including 0,036 % phosphorus, 0,015 % sodium and 0,06 % potassium. With this structure of husk, due to its high fibre content and stiffness, trauma to the gastrointestinal tract may occur. It's not a good idea to use husk in this form. In order to get a complete feed additive, we have developed a special technology of buckwheat husk processing. Our husk treatment reduced the fibre content to 32 %. The digestibility of processed husk totalled 77,4 %. On the basis of the new technology, Technical specifications for the production of feed additive with inclusion of buckwheat husk have been developed and approved. Thus, we draw the following points:

- special husk processing technology increases its fodder quality and digestibility;

- processed buckwheat husk can replace 20 - 25 % of grain components in animal diets, practically without reducing feed value.

3. Buckwheat husk - the key to a good sleep!

The husk of buckwheat is also used extensively in the manufacture of seats and pillows. Before use as a filling material, the husks are repeatedly cleaned and calibrated, washed and dried, carefully blown to remove various impurities and dusts. Absolutely clean and dry filling is carefully placed in special covers - and you get an orthopaedic pillow from buckwheat husk with all its advantages and useful properties.

This filling really effectively follows the contours of the body. This fact has been verified by experience as well as numerous positive consumer reviews. Such filling ensures the correct position of the neck and head, supports the right shape, thus helping to prevent neck pain and unpleasant muscle discomfort. You should know that you shouldn't wash your buckwheat pillow, as exposure to humidity will negatively affect the properties of the buckwheat husk. Exploatation period of these pillows is 1,5-2 years. But feather pillows also don't last very long. In the case of buckwheat husk filled pillows, there are definite rules for the care of such pillows. After the recommended service life it is only necessary to replace the husk in the pillowcase with a new filling.