07.12.2023

When choosing directions for starting new business projects, everyone pays attention to the already existing experience of realized projects. And more often the important question of what equipment has become a profitable purchase and investment for grain processors. Taking a summary of this year's orders, it is possible to clearly identify the sales leaders.

So here we go, sharing the results of our analyses below:

It's designed for the production of complete loose feed according to a given recipe, satisfying the needs of all types of poultry, pigs and cattle in mineral, nutrient and biological substances. The productivity differs from 0,7 tonnes/hour to 3 tonnes/hour depending on the type of feed plant.

Causes of popularity:

- quality feed is here and now! – It means reducing the cost of feedstuffs and minimising costs for their transportation;

- guarantee of feed quality - the horizontal mixer provides up to 97 % homogeneous mixing of six different raw materials. It also allows the injection of liquid components;

- it is possible to change the seasonal adjustment of feed ingredients, it is possible to experiment with feed compositions to achieve the desired characteristics. The presence of a controller allows for instant recipe changes;

- control of dosage of feed components. Pneumatically loaded tensometering (gauging) system ensures high dosing accuracy and minimises work costs;

- the unit is assembled like a pre-assembled construction set and does not require a special building;

- one operator with the relevant level of training is sufficient to operate the plant.

As a result, you get the quality of the feed produced in accordance with the relevant state feed standard norms.

Aggregate roller mill АВМ-15 is designed to mill grain for flour. This mill is the complex of small-sized cleaning, grinding, sieving, transport and electric equipment. Such mills are particularly favoured by those agrarians, who appreciate the benefits of flour as an input product. Usually, the purchasing of such mills is resorted by farmers who have available their own raw material (grain). Their next step is production of flour for further use in the food industry (bakery etc.) or for flour sale, including for export.

Why is it popular? - Small dimensions and weight, high quality and yield of the produced flour with low power consumption favourably characterise these units from their analogues. A great advantage is that all the mill mechanisms are mounted on a special prefabricated metal base. This makes it unnecessary to construct a special building. As a rule, the mini-mill АВМ is installed in a hangar up to 6 metres of high, which is both a warehouse for raw materials and finished products. It’s so comfortable that all parts of mills are in special modular base on two floors. Due to the complete automated and mechanised technological process of grain milling, only 2 persons are required to operate the mills!

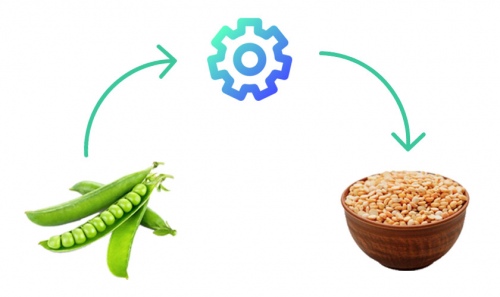

The first position! The sales leader among the processing complexes is Groats mini factory Р6-МКЦ-15

It provides a capacity of up to 15 tonnes of processed grain per day. Such plants are successfully operating in Ukraine and in European countries. The particular feature of the Groats mini factory Р6-МКЦ-15 is that it can process a minimum of three types of cereals (peas, barley and wheat). And if the plant is completed with a germination unit, it can also process the corn.

Causes of popularity? Possibility to produce 3-4 cereal types on one unit, at the same time guaranteeing high quality cereals! The “mini factory” is a small-sized (compact) unit, which mounted on a compact metal structure and placed in a single-floor building (it needs just a hangar up to 6 m high). Such building usually is two-in-one, namely it is both a warehouse for raw materials and finished products. An advantageous fact is that it is possible to produce a range of 4 cereal products.

The payback period for each of the top lines is up to 1 year, which is a determining criterion when choosing a direction for investment.