Purpose:

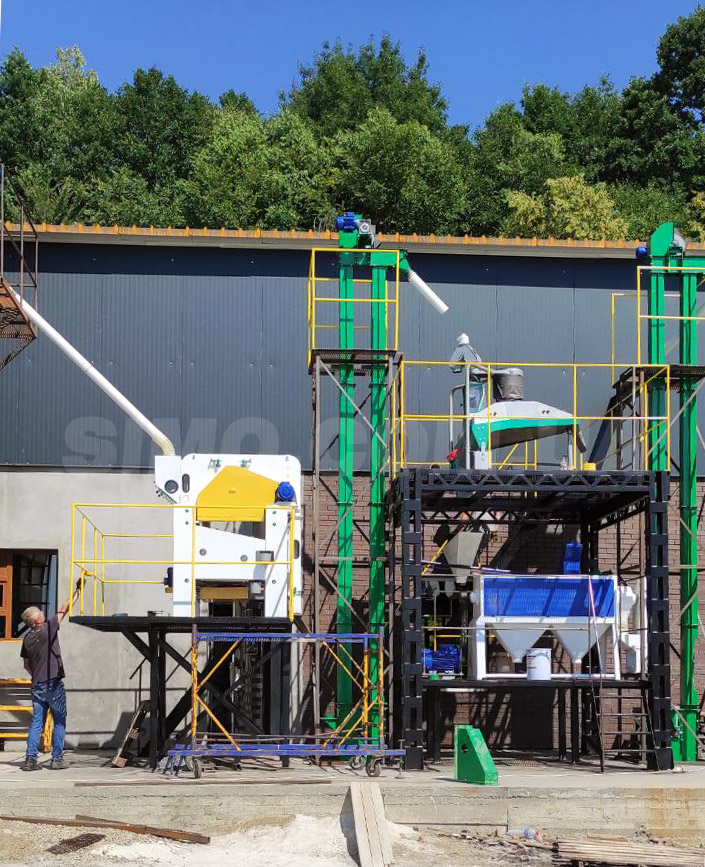

Aggregate roller mill Р6-АВМ-15 is designed to mill grain for flour (premium and first class only). Technological equipment has a remote control for operating. This mill is the complex of small-sized cleaning, grinding, sieving, transport and electric equipment.

Small sizes, small weight and high quality of flour, and less energy consumption are so good components - this is a profitable proposal.

It’s so comfortable that all parts of mills are in special modular base on two floors. Therefore, you don’t need special building. It takes two persons to operating due to full automation and mechanization of grain grinding process.

Specifications:

| Parameter |

АВМ - 15 |

| 1. Capacity (two classes, flour yield 72%), t/day |

15 |

| Including: |

|

| - Premium class flour, % |

48 - 50 |

| - First class flour, % |

22 - 24 |

| 2. Length of roll line |

150 |

| 3. Sieving surface, m2 |

21,2 |

| 4. Transportation line |

Pneumatic |

| 5. Individual transmission |

|

| 6. Quantity of electric motors, pcs |

9 |

| 7. Installed power, kWt |

1,1 - 11 |

| 8. Total power of electric power, kWt, no more than |

35,3 |

| 9. Weight of mill, kg, no more than |

7 500 |

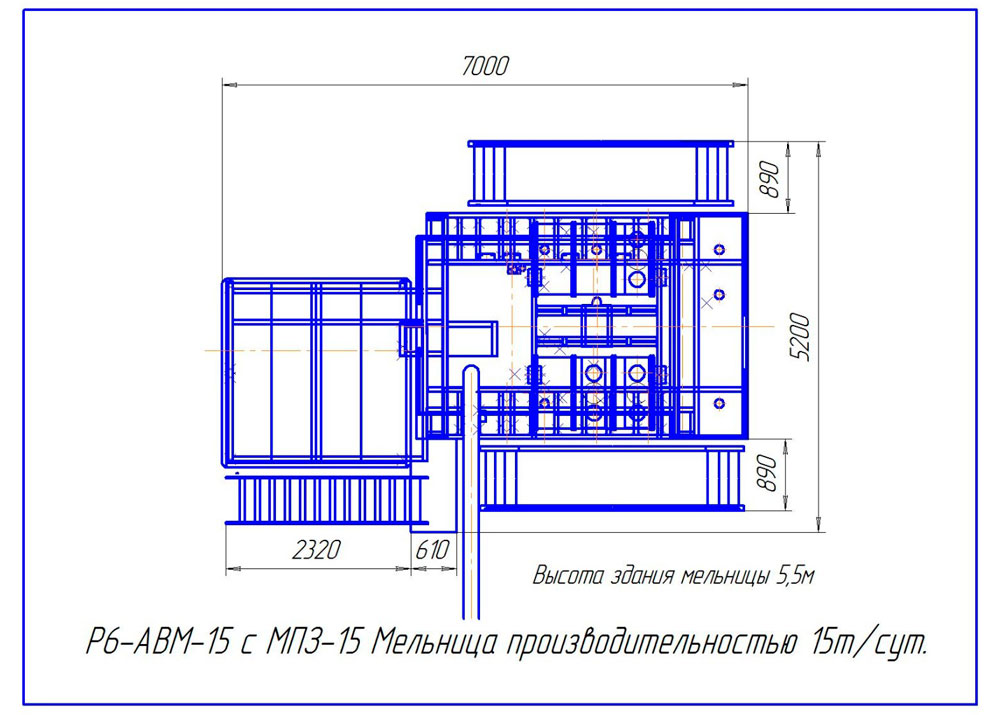

| 10. Dimensions, mm, no more than |

|

| - Length without hopper and stairs |

7 000 |

| - Width without ramp |

3 400 |

| - Height without technological frame |

5 000 |

Operator shall have special training, to know operating rules for mill operation. Building for mill should comply with BII-a Class. Dust concentration on working place shouldn’t exceed 4 mg/cm3 (grain) and 6 mg/sm3 (flour). Equivalent noise level shouldn’t exceed 80 dBa. Equivalent value of vibrospeed – 92 Db.

Requirements to the customer on the readiness of the building at the time of installation of Aggregate roller mill Р6-АВМ-15:

1. Building.

a) It should comply with B-2a Class (с СНИП2.1005-85 «factories and buildings for grain storage and processing»;

b) Minimum inside sizes for type planning:

- length - 9 m., width – 7,5 m., height - 6 m. – for АВМ-7

- length - 15 m., width – 8 m., height - 6 m. – for АВМ-15

- length - 18 m., width – 9 m., height - 6 m. – for АВМ-15 with МПЗ and СВМ

c) It shouldn’t be pillars, protruding beams etc. there;

d) The doorway for the delivery of equipment must be at least:

- width - 2,5 m;

- height — 2,2 m;

e) The floor should be hard (concrete);

f) Building should have 380V alternating current and lighting;

g) Doorway and windows should be closing.

2. Foundation for Aggregate roller mill Р6-АВМ-7 (customer builds).

I Version:

2.1. It should carried out as per attached drawing to the passport of mill.

2.1.2. Anchor bolts should be changed with embedded plate.

2.1.3. Embedded plates should be lies above floor level on 200 mm.

2.1.4. Distance from wall to the nearest embedded plate should be at least 2 m.

II Version: (the most appropriate)

2.2. Mill should be installed on technological frame. The frame is not included in complete set of mill АВМ-7.

2.2.1. Channel – 16, 40 m.

2.2.2. Welding machine and electrodes.

2.2.3. Hard floor (concrete). Mill Р6-АВМ-15 completed with technological frame.

3. Must have:

3.1. Welding machine and electrodes.

3.2. Gas cutter.

3.3. Electric drill.

3.4. Power cable 4-core (to provide input voltage).

3.5. Lifting device up to 1 ton.

3.6. Grain for testing.

3.7. 2 people (miller) for training.

Delivery of technological equipment and components is carried out in one of the options:

- Foreign economic contract on FCA terms. The cost of shipping paid by the customer.

- Internal contract including delivery and full customs clearance. AGRO-SIMO-MASHBUD undertakes all organizational questions on delivery and customs clearance.

The production term of equipment takes from 80 to 110 working days (depending on a season).

Delivery time from the date of equipment readiness on average from 7 to 21 working days. Final dates are regulated individually.

Terms of payment. 70% prepayment, 30% - upon availability of equipment.

GUARANTEES. The warranty period of the equipment is 12 months from the date of commissioning, but not more than 15 months from the date of shipment. Warranty does not apply to rapidly wearing parts. The manufacturer guarantees the normal stable operation of the equipment under the conditions of consumer compliance with the rules of transportation, storage and operation. In case the manufacturing defects detected during the warranty period, the manufacturer’s service solves the problem at its own expense.

Production of high-fiber flour. More>>>

Development of flour mill production. New mills. More>>>