Purpose:

Aspirating chamber БСХ-100 is designed to separate aerodynamic light impurities from the grain. The chambers are installed in grain cleaning departments of elevators, groats mills and mills, complete with separators such as БСХ-100, БСХ-16, БСХ-12, БСХ-6, БСХМ-16 and they could also be operated as unique units.

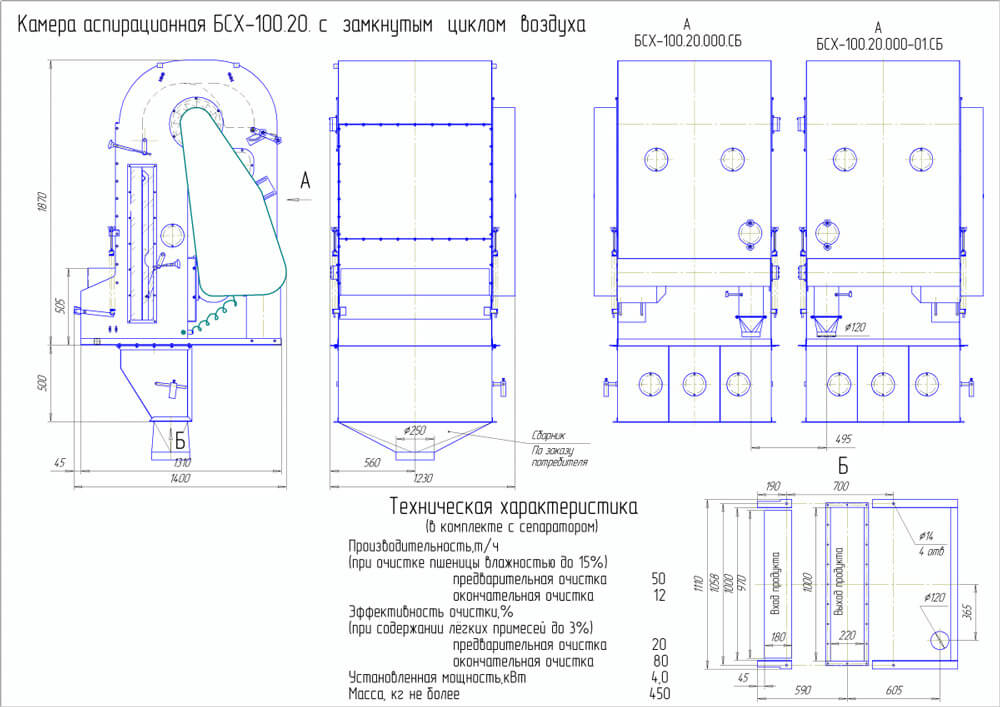

Specifications:

| Parameter |

БСХ-100.20 |

| 1. Technical productivity, t/h, min: |

50 / 12 |

| 2. Technological efficiency, %: |

20 / 70 |

| 3. Finish product content in sediment chamber, %, max |

2,0 |

| 4. Dimensions of pneumatic separating channel, mm: |

- length |

1 400 |

| - width |

1 000 |

| - height |

1 200 |

| 5. Diameter fan: |

- rotor diameter, mm |

320 |

| - quantity of rotor blades, pcs. |

12 |

| - rotor rotation speed (RPM) |

750 |

| 6. Auger for go waste off: |

- auger diameter, mm |

160 |

| - rotation speed of auger roller, (RPM) |

350 |

| 7. Nominal power of engine, kW, max |

4,0 |

| 8. Dimensions, mm: |

- length |

1 400 |

| - width |

1 220 |

| - height |

2 370 |

| 9. Weight, kg |

600 |

Design and operation:

Aspiration chamber БСХ-100.20 consists of the chamber itself, the outlet box and the collector (at the consumer’s request). To supply the product into the pneumatic separation channel of the chamber evenly, a receiving box with a spring-loaded tray is provided, which makes it possible to distribute product along the length of the channel. The chamber body is a prefabricated welded structure made of sheet steel, in which vertical pneumatic separation and recirculation channels, sediment chamber are formed by the inner walls and partitions. A cross-flow fan (rotor) and an auger are built into the sedimentation chamber along the length of the machine for removing the sedimentary sediment. In the lower part of the pneumatic separation channel, an outlet box with a flap for removing the cleaned product from the chamber is bolted to the chamber. The back-up of the product in the box is regulated by the movement of the load on the damper pin that eliminates air leakage into the cavity of the pneumatic channel.

The pneumatic separation channel serves to separate light impurities from the product. It consists of side walls of the housing and a movable wall. The wall consists of two hinged parts. The upper and lower parts can be moved using the handles. This changes the profile of the section of the pneumatic separation channel and, accordingly, the air velocity in the vertical section. The air flow rate in the pneumatic channel is regulated by the throttle valve using the handle 6. Visual control of the separation process can be carried out through the viewing windows.

To adjust the operation of the pneumatic channel, it is necessary to set the movable wall in a vertical position or so that the channel narrows slightly downward. By adjusting the depth of the channel and the amount of air, the product quality is achieved according to the requirements set.

The rotor of the cross-flow fan is welded construction with welded blade’s discs. The rotor operates in bearing units. The auger is attached to the chamber body with bolts and serves to remove the products deposited in the sediment chamber. The auger shaft is mounted on two spherical ball bearings. On the opposite side of the drive, on the auger, there is a branch pipe for withdrawing the relays, to which an anti-suction valve is attached. For mounting and cleaning the inner surfaces of the chamber, covers with rubber seals are installed in the sides of the body. The fan and auger are driven in rotation from an electric motor mounted on the plate, through V-belt drives and a counter drive. The counter drive serves to tension the V-belt going from the fan to the auger.