Purpose:

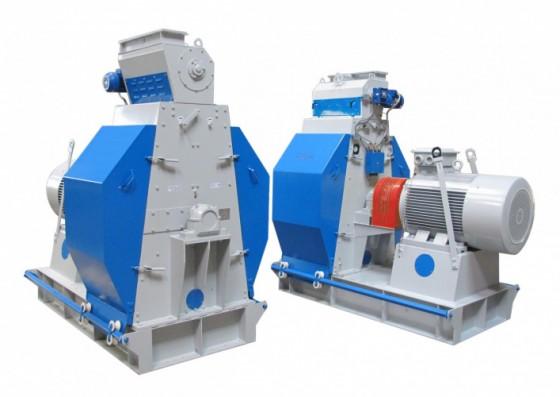

Vertical hammer mill А1-ДМ2Р is designed for crushing grain of cereals, husk, legumes, corn, grain mixtures, meal, small-size cake and other types of raw materials, except for mineral. It can be used independently or as part of technological lines and units.

Vertical hammer mills are manufactured according to the 3rd category of State Standards 15150 in climatic version "У" for the domestic market and export to countries with a temperate climate.

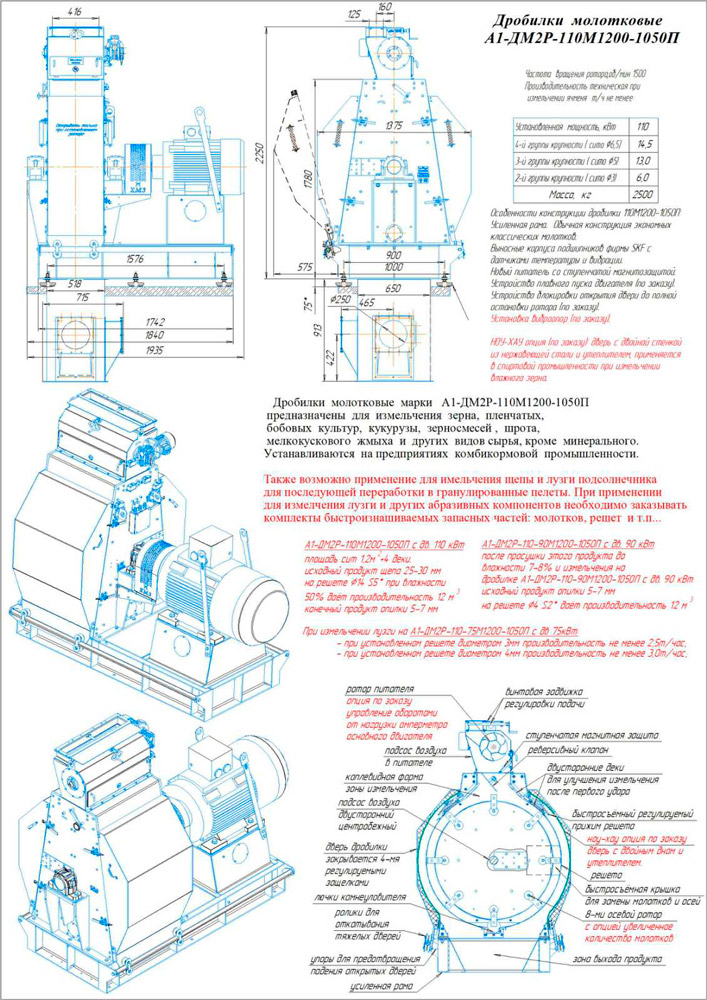

Specifications:

| Indicators |

А1-ДМ2Р-55 |

А1-ДМ2Р-75 |

А1-ДМ2Р-110 |

А1-ДМ2Р-160 |

А1-ДМ2Р-200 |

| 1. Technical productivity for grinding barley with a moisture content of no more than 15.5% with a bulk density of 0,68 t/m3, t/h, at least: |

| - up to the 4th size group; Ø6 and Ø8 |

6,5 |

10,0 |

14,5 |

22,5 |

28,0 |

| - up to the 3rd size group; Ø5 |

4,5 |

8,0 |

13,0 |

17,0 |

21,0 |

| - up to the 2nd size group; Ø3 |

2,5 |

3,5 |

6,0 |

8,0 |

10,0 |

| 2. Total installed power, kW, no more |

55,55 |

75,55 |

110,55 |

160,55 |

200,55 |

| 3. Rotor speed, RPM |

1 500 |

| 4. Circumferential speed of the rotor hammers, m/s |

91 ± 3 |

| 5. Overall dimensions, mm, no more: |

| - length |

1 600 |

1 650 |

1 950 |

2 350 |

2 350 |

| - width |

1 370 |

1 370 |

1 370 |

1 370 |

1 370 |

| - height (without explosion chamber) |

2 250 |

2 250 |

2 250 |

2 250 |

2 250 |

- feeder 07 |

2 800 |

2 800 |

2 800 |

2 800 |

2 800 |

| 6. Weight of the actual mill (without spare and replacement parts, electrical panels and control panel), kg |

1 440 |

1 765 |

2 290 |

2 600 |

3 400 |

| 7. Air consumption for aspiration, m3/hour |

2 700 |

2 700 |

3 600 |

4 200 |

4 200 |

| 8. Service life, years |

8 |

Attention! Increasing moisture will reduce machine performance. So, when humidity increases up to 20%, productivity decreases by 30%.

*The 4th coarseness group is obtained when sieves with 6 mm holes and a combination of sieves with 6 and 8 mm holes are installed into the machine, the 3rd coarseness group is obtained when sieves with 5 mm holes are installed.

Design and operation:

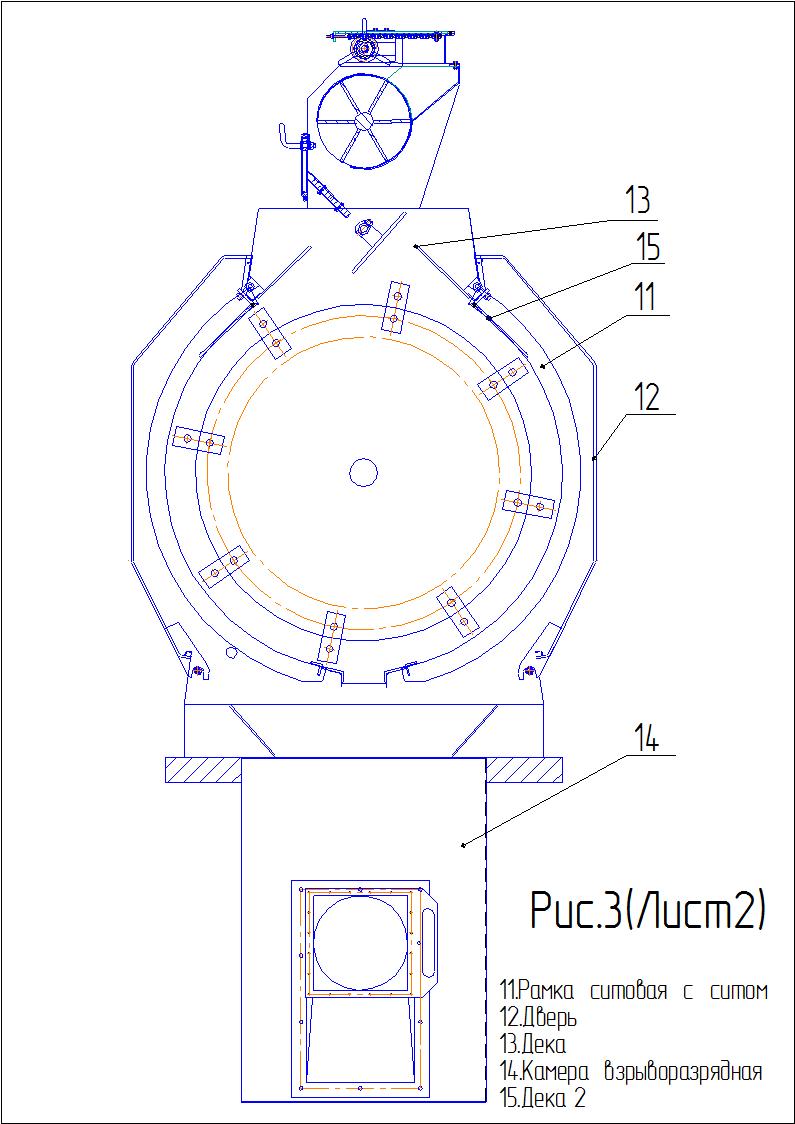

The machine (Pic. 3 sheets 1-2) consists of frame (1), housing (2) (mounted in the frame), rotor with hammers (3) are installed in bearing housings (5); feeder (4), rocker valve (6) and a clutch (8) are directly connected to an electric motor (9) with a rotor, a frame sieve with a sieve and deck (11), doors (12). Inside the body in its upper part, there are special decks (13). Terminal box (10) is fixed on the mill body.

Extremely gentle operation for sieves and impact plates thanks to the integrated foreign body pocket in the working chamber.

The electrical equipment of the mill includes: a rotor drive motor, a feeder drive motor, five limit switches, a terminal box, as well as optional mill controls and protective equipment (soft starter or frequency converter). Control box installed in a separate production room, emergency push-button post and control panel - on the wall or column next to the machine.

Recommended wiring diagrams for electrical equipment you can find in Pic. 6-7.

The installation of sensors for monitoring the temperature of the bearings and the crushing chamber is provided. The feeder is designed for uniform feed of raw materials into the crushing chamber and the release of metal-magnetic impurities at the same time (i.e., magnetic protection of the working parts of the crusher from the ingress of metal-magnetic impurities and elimination of sparks).