Purpose:

Horizontal dehuller Р3-БГО-8 destined for dry dedusting of grain, cleaning from partial separation of shell, brush and grain germ at flour mills and for barley and wheat pre-hulling.

Specifications:

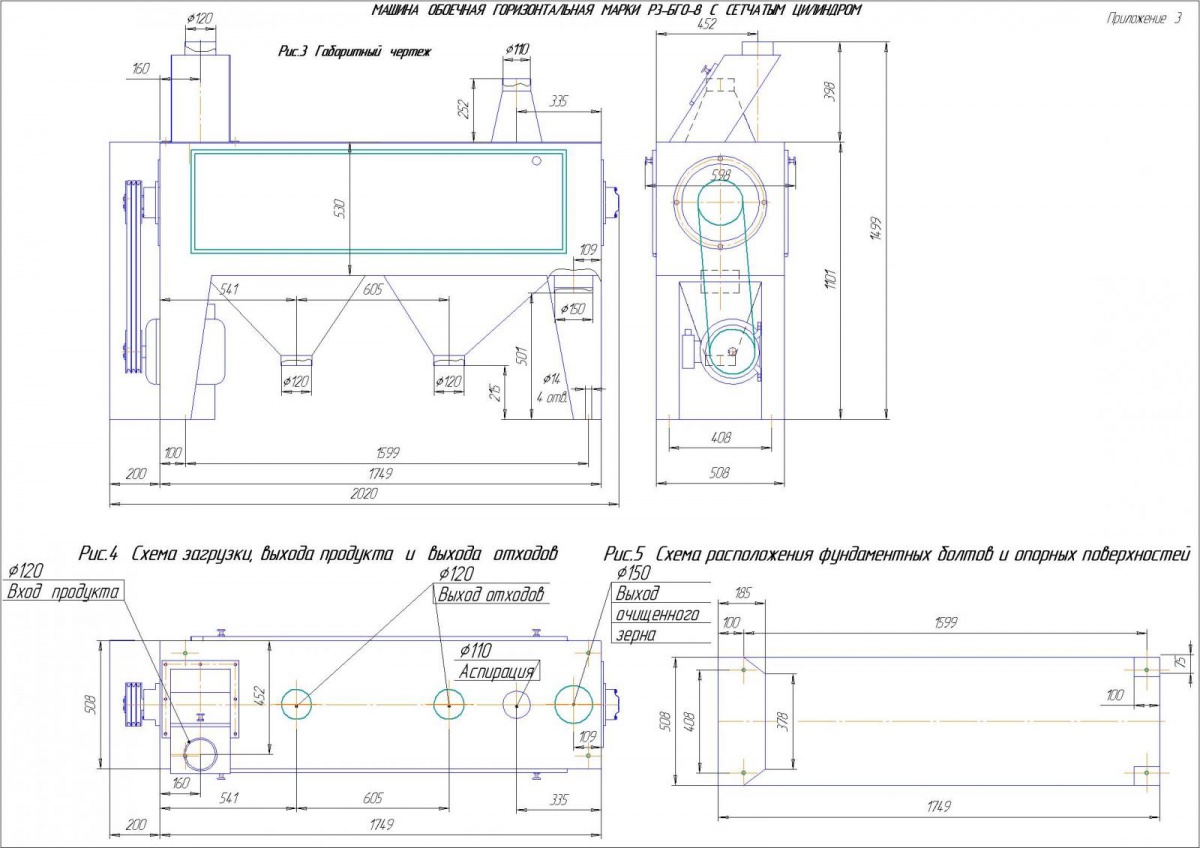

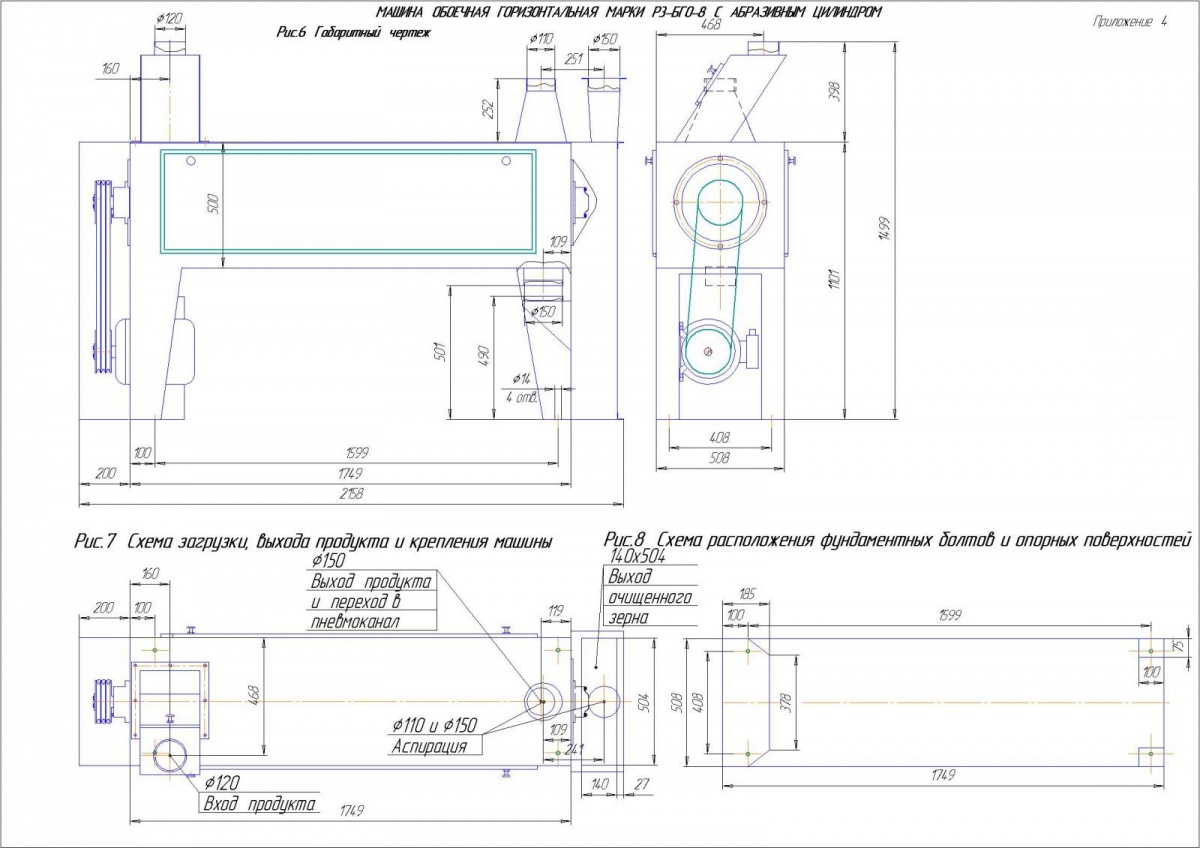

| Parameter |

РЗ-БГО-8 with a sieve cylinder |

РЗ-БГО-8 with an abrasive cylinder |

| 1. Capacity, t/h |

7 - 9 |

3 - 5 |

| 2. Installed power, kW, max |

11 |

11 |

| 3. Rotor speed rate, RPM: |

|

|

| - to clean wheat grain |

1 085 |

1 085 |

| - to clean barley grain |

- |

1 450 |

| 4. Aspiration air flow, m3/h, max |

800 |

800 |

| 5. Weight, kg, max |

485 |

690 |

| 6. Dimensions, mm, max: |

|

|

| - length |

2 020 |

2 158 |

| - width |

598 |

620 |

| - height |

1 500 |

1 500 |

Note. Barley and wheat dehulling achieved by changing the circumferential speed of the rotor, the gaps between the scourges and the abrasive surface.

Design and operation:

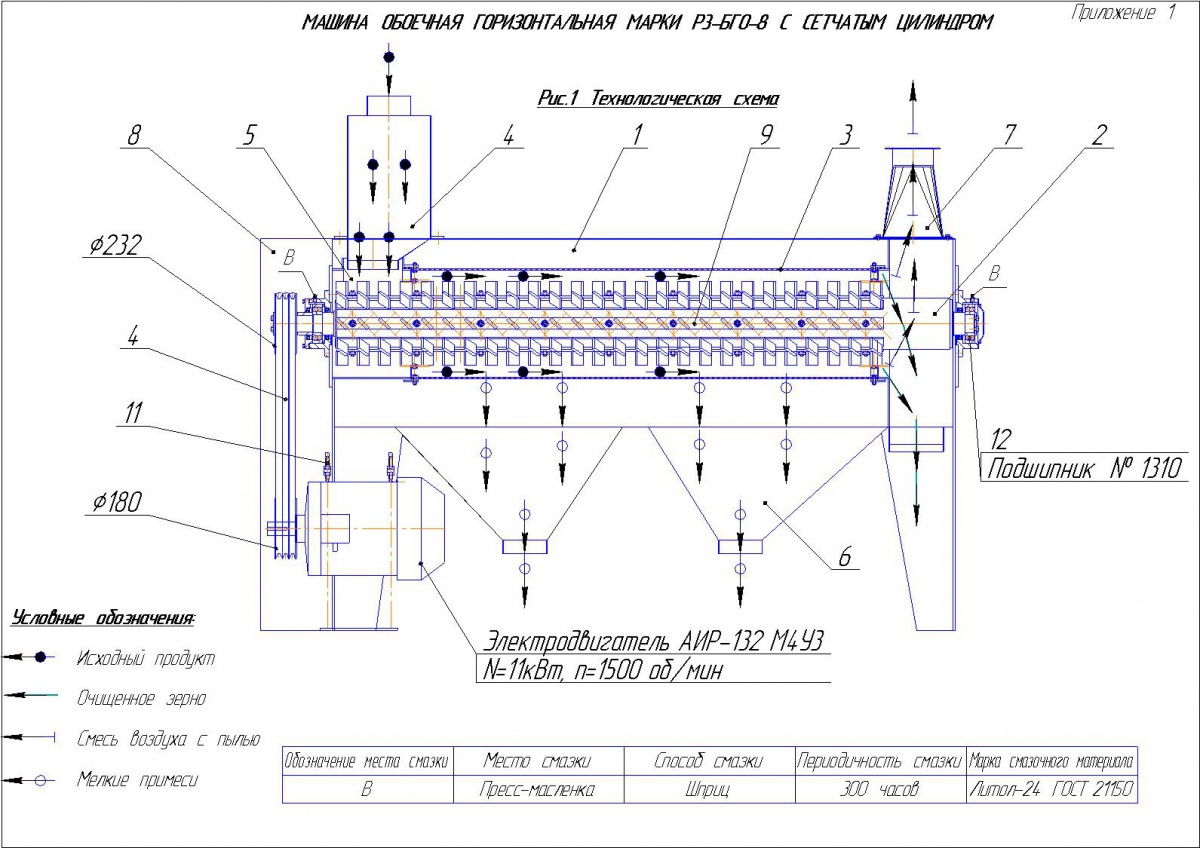

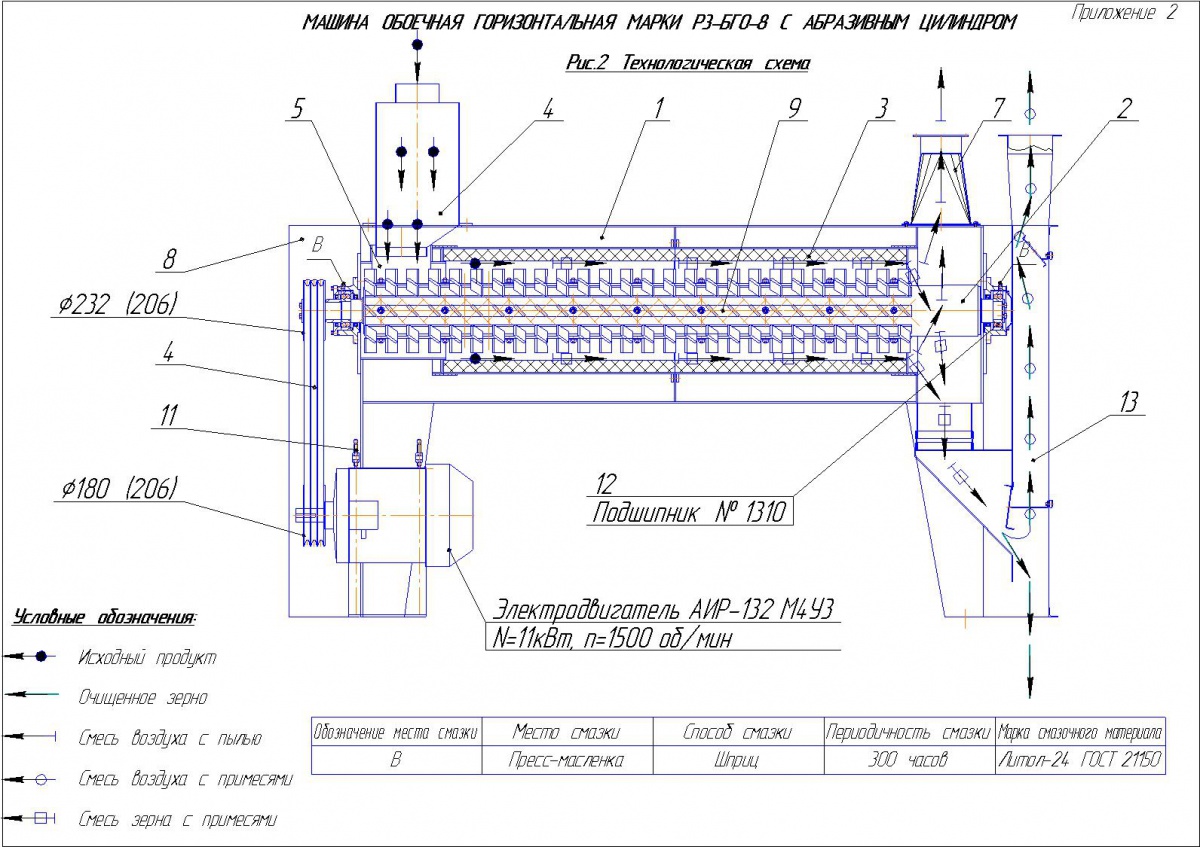

Horizontal dehuller consists of body (1), impact rotor (2), mesh and abrasive cylinder (3), receiver (4), feeder (5), hopper (6), suction nuzzle (7), fence (8), pneumatic drive (13), tension screw (11), support bearing (12) (pictures 1,2).

Grain goes into machine through the receiver. The grain is evenly distributed and cleaned from metal impurity. Then it goes to feeder, and the grain is captured by rotor scourges. These scourges distribute the grain in the abrasive cylinder.

Intensive cleaning is ensured as a result:

- Friction between grains;

- Friction between grains and scourges;

- Friction between grains and mesh of cylinder.

Such processing leads to the fact that:

- removal of impurities from the surface of the grain;

- partial removal of shell, brush and grain germ;

- grinding of lumps of ground and removal of they;

- grinding and removal of empty grains and the grains damaged by insects .

If the machine made with mesh cylinder, small impurities are removed through the mesh. And they go out due to hoppers. The clean grains are removed through the outlet nuzzle. Dirty air out from suction nuzzle.

If the machine made with abrasive cylinder, the clean grains with small impurities are removed through the outlet nuzzle, and the dirty air is through the suction nuzzle. Then the grain goes to the pneumatic drive, where it where it clean additionally, with which small impurities are removed.

The drive for rotating the rotor of the machine is V-belt drive. For the drive, standard 11 kW motors are used. V-belts are tensioned using tensioning screws. The working body of the machine is a horizontal rotor. It consists of hollow shaft with welded trunnions and scourges 45° welded.

Attention! If for any reason replacement of one scourge is required, then the opposite scourge must also be replaced.

If possible, it's recommended to replace the complete set. After replacement of scourges, the rotor should be balanced dynamically. The mesh cylinder consists of two halves connected in a horizontal plane. The cylinder is mounted on the feeder and the inner wall of the machine. Abrasive cylinder consists of two halves connected by flanges and partition in machine's body.The cylinder is attached to the feeder and the inner wall of the machine body using clamps. In order to uniformly wear the surface of the mesh (abrasive) cylinder during its operation, it is recommended to turn the cylinder 180°.

The abrasive surface of the cylinder has made from a mixture of the following composition:

- Abrasive parts (state standard (ГОСТ) 3647-71 69-76%);

- Caustic powder by magnesite (state standard (ГОСТ) 1216-41 14-17%);

- Technical magnesium chloride (state standard (ГОСТ) 7759-73 10-14%)

When cracks appear, abrasive surface repair is allowed:

- blow sandpaper cracks with compressed air;

- fill all existing cracks with the prepared mixture;

- keep the swamped (filled) parts in dry warm room at a temperature of at least 30 °C and a relative humidity of 55-70% for 3 days;

- after the expiration of the period, check the quality of repair, in case of cracks, fill again.

If the abrasive surface worn extensively, causing an increase in the number of broken grain more than acceptable (grain break in the machine no more than 1%), the abrasive cylinder should be changed.