Appointment:

The unit is intended for the production of complete loose feed according to a given recipe, satisfying the needs of all types of poultry, pigs and cattle in mineral, nutrient and biological substances.

Dosing (up to six components) is carried out by the operator under the control of the strain gauge system with indication of weight, light and sound signalling of the obtained weight of each component being ground. This machine can be used in poultry farming and livestock farming. Farmers should add necessary premixes and albumen mineral substances to feedstuff.

Distinctive features of Mini feed plant МКУ, in comparison with existing models of other manufacturers:

- Horizontal mixer provides uniformity of mixing (up to 97%) and help to add fluid materials like oil;

- Stain gauge system with pneumatic discharging provides high metering accuracy and minimizes labour costs;

- Conroller provides quick change of recipe;

- It's enough to have one professional operator for service the machine;

- The ability to use up to six different raw materials;

- Quality of feedstuff conforms to State Standard;

- Reliable operation at temperatures from -10 ° to + 40 ° C, humidity 80%, pressure 650-800 mm Hg;

- 15 months of warranty.

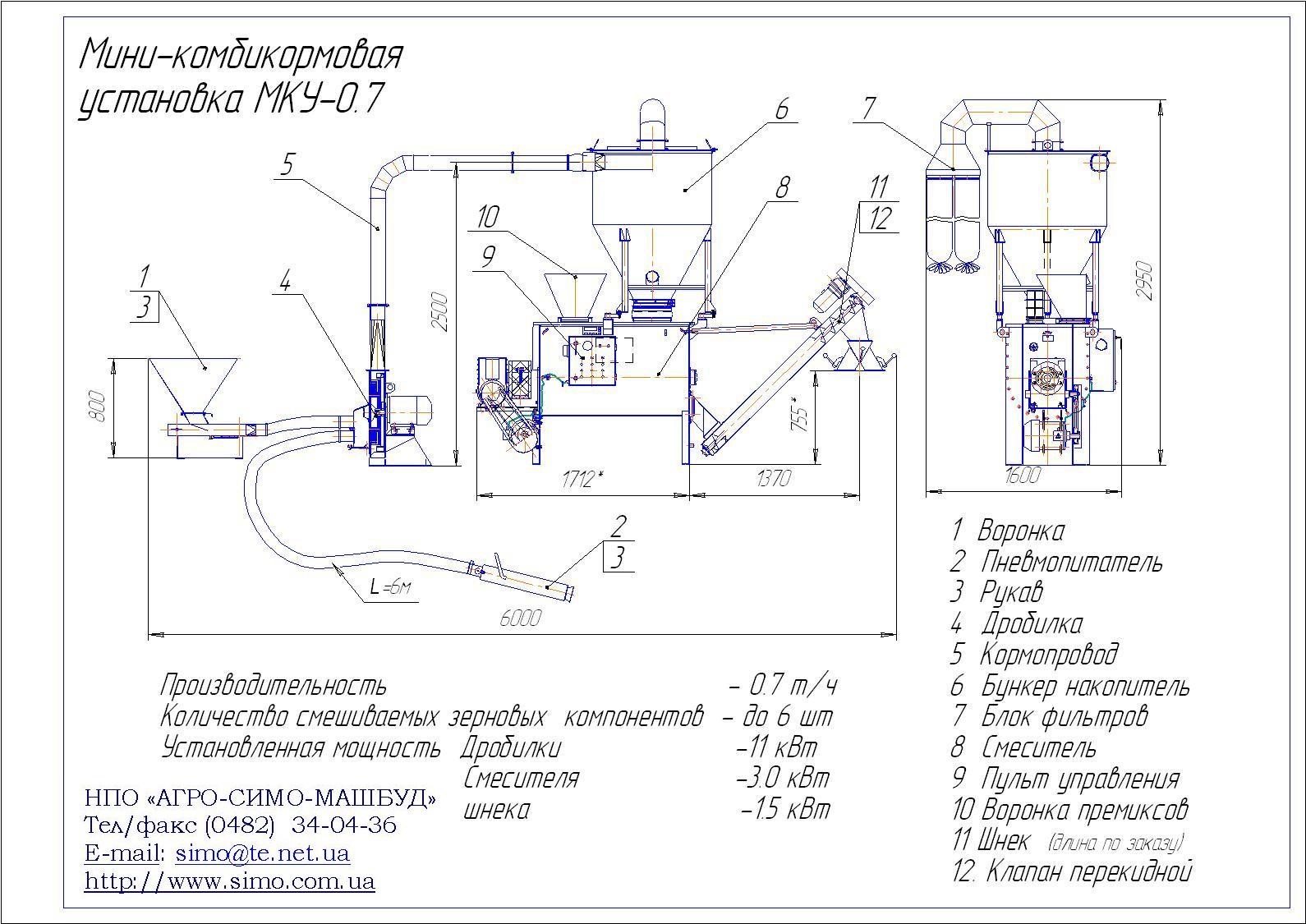

Machine structure:

- Receiving hopper for discharging of raw material;

- Pneumatic feeder for taking of grain and transporting it through pneumatic transport to the grinder;

- Vertical mill А1-ДМ2Р for grinding of grain and concentrate high-protein meal (schrot);

- Parts of pneumatic transport for transporting grain and finish product;

- Storage hopper installed with 3 stain gauges for sequentially weighing each component of the feedstuff on electronic hopper scales, followed by inlet of a portion for mixing.

- Horizontal mixer for qualitative component mixing after its dozing. The mixer provides the ability to manually add necessary components, such as vitamins, premixes, (also the possibility of introducing liquid components).

- Filter block for air clearance while discharging broken material from grinder into storage hopper.

- Screw conveyor for finish product moving into transport or sewing machine;

- Controller with stain gauge system;

- Control cabinet.