Purpose of equipment:

Plansifter is designed to sort cereals (remove impurities, size before dehulling, collect intermediate products of dehulling and polishing, grade and control products) at cereal production facilities.

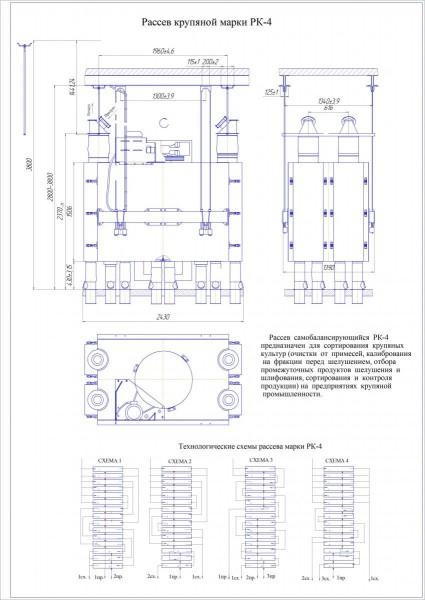

Specifications:

| Indices |

РК-4 |

РК-2 |

| 1. Capacity, t/h |

6 - 8 |

2 - 4 |

| 2. Quantity of sections (inlets) |

4 |

2 |

| 3. Estimated sifting frame sizes, mm |

400х800 |

| 4. Total estimated useful area, sq.m. |

13,5 |

6,75 |

| 5. Housing circular vibration rate, с-1 |

3,0..3,2 - 3,7..3,8 |

| 6. Radius of circular vibration, mm |

28 - 22 |

| 7. Aspiration air flow, cubic m/h |

900 |

420 - 540 |

| 8. Electric drive power, kW |

3,0 |

| 9. Dimensions (max), mm: |

| - length |

2 430 |

1 930 |

| - width |

1 440 |

1 100 |

| - height |

2 370 |

2 500 |

| 10. Weight, kg |

2 200 |

1 800 |

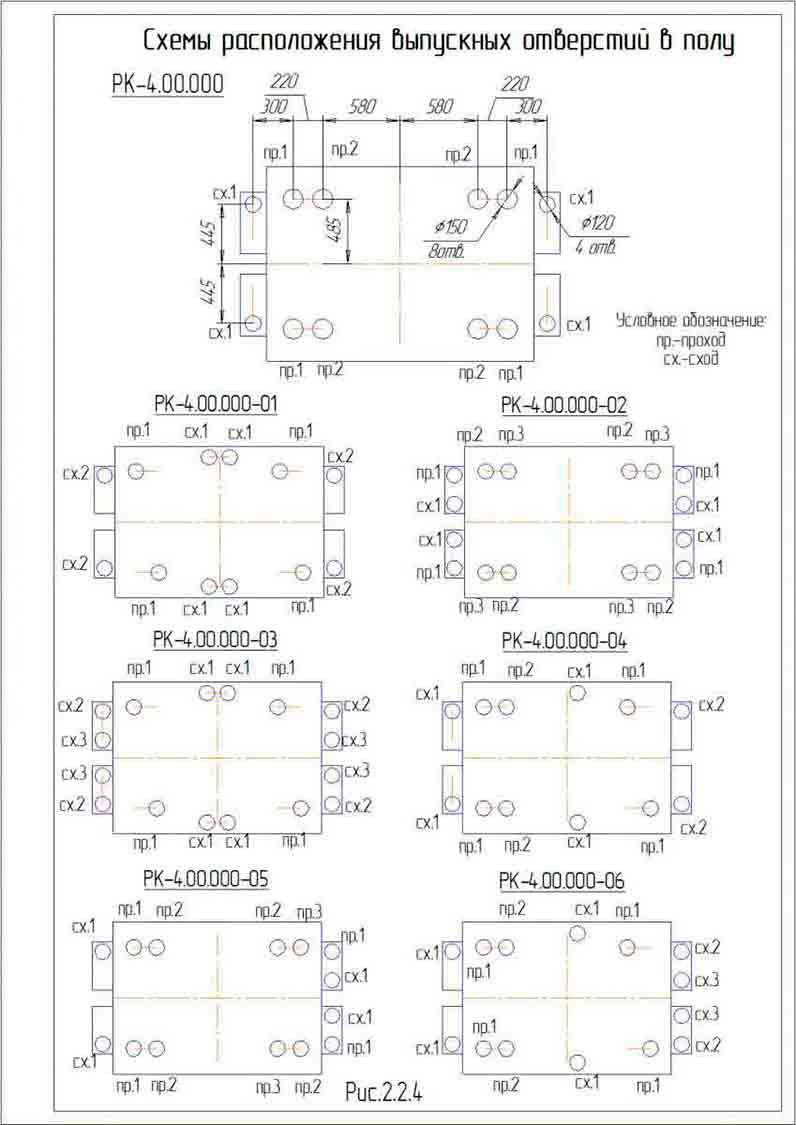

Plansifter is made in ten versions, differing in functional schemes of sections.

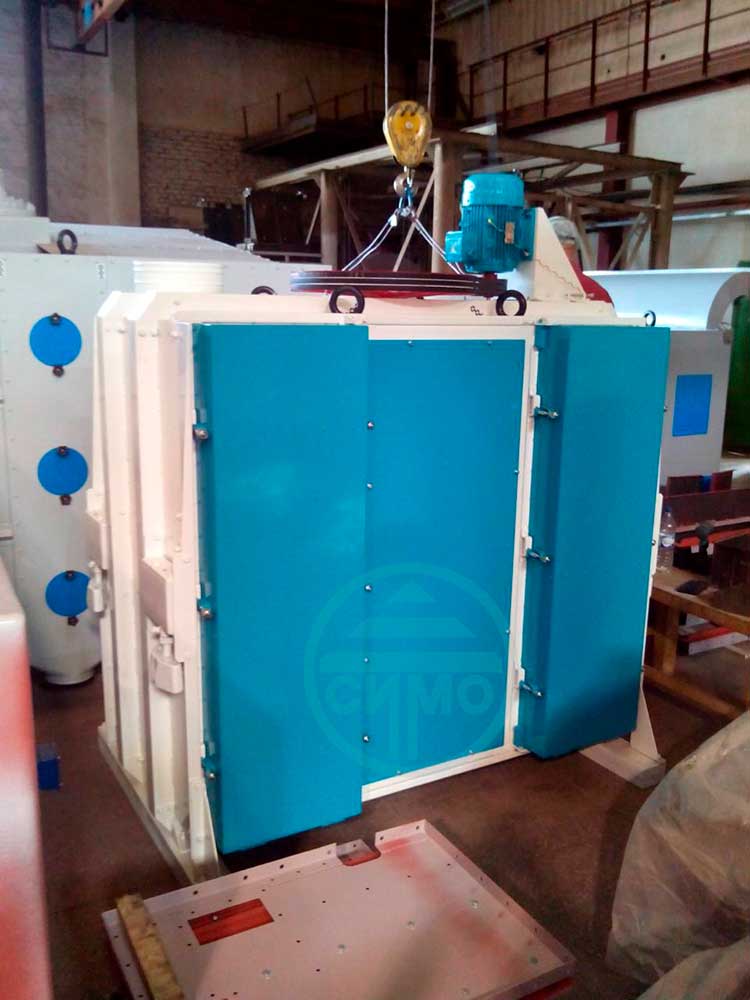

Design and operation:

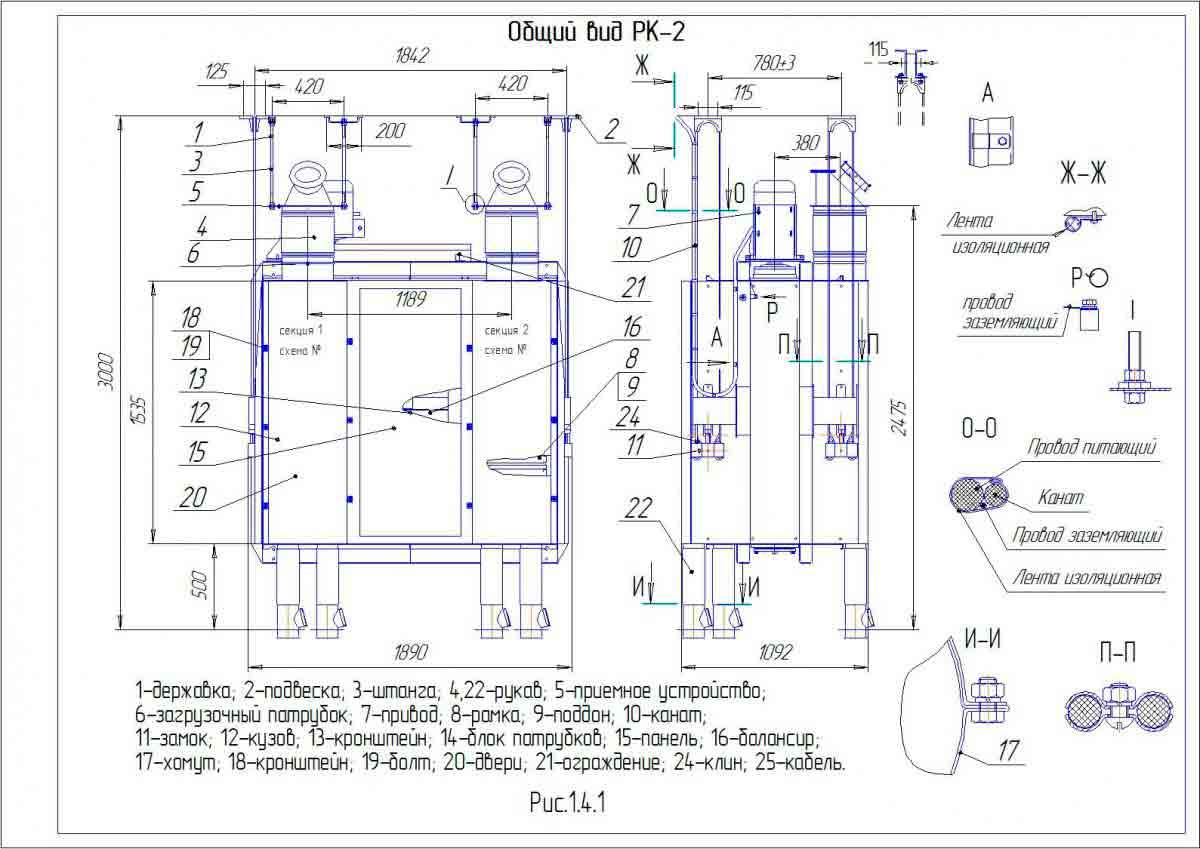

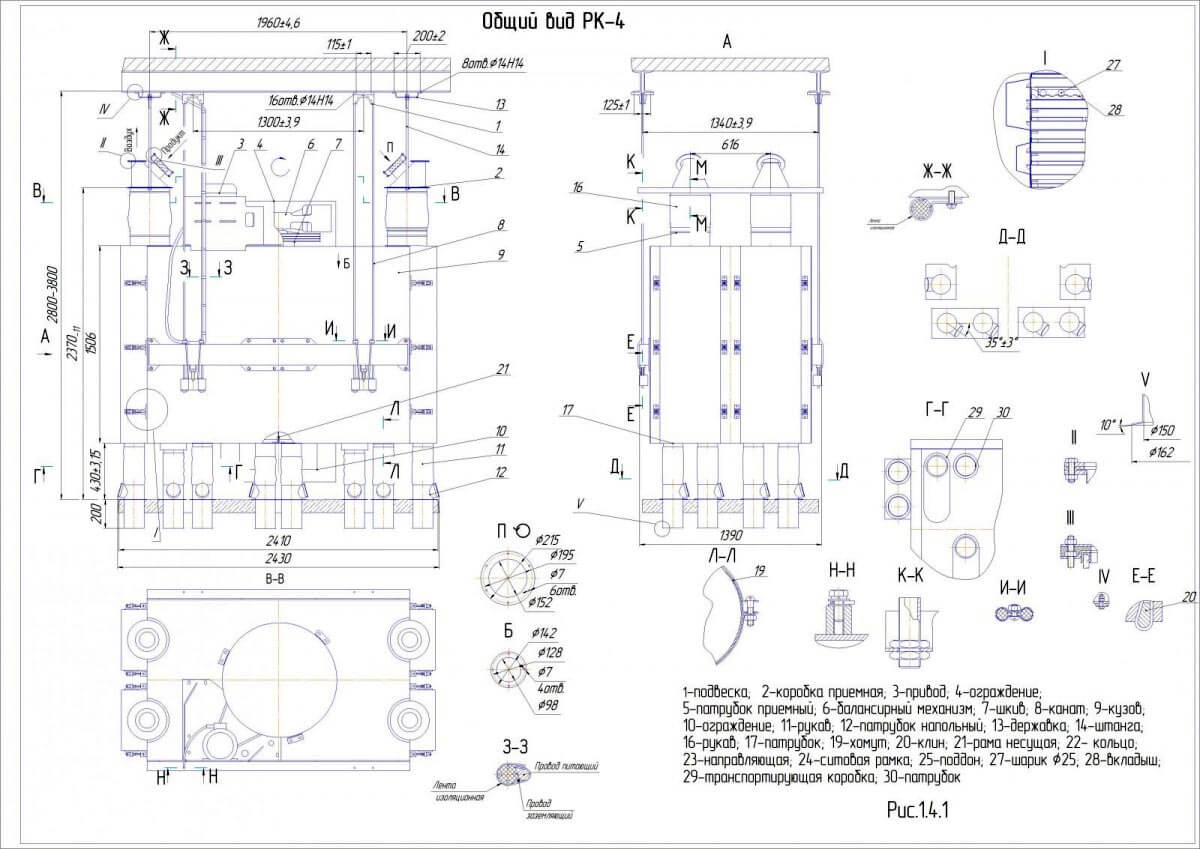

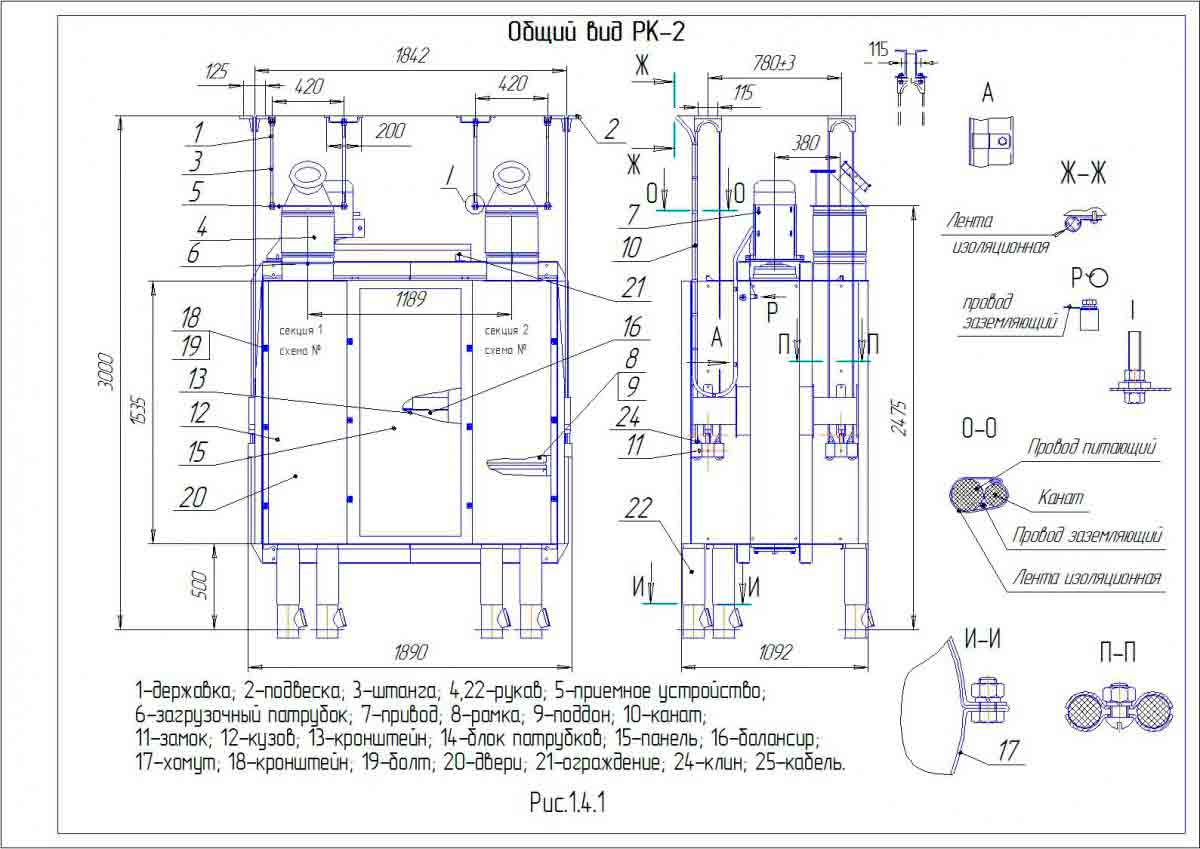

This machine is cabinet type collapsible construction with retractable sieve frames. The plansifter consists of sieves body (1.4.1), support frame (21), balancing mechanism (96) and drive (3). The plansifter hang on steel cables going to suspensions (1). These suspensions mounted to the ceiling frame. Body selected on 4 sections by partitions of support frame.

There are 15 sieve frames (24) with pallets (25), frame (6) in the guides section (23). The outer skin of the body and the sections guides are forming the side bypass channels. The doors of sections have double walls, which form the bypass channels on the receiving side. From the opposite side, the bypass channels of sections look like removable junction boxes wich mounted to back rack of secrtions.

Sieves cleaning realized by rubber bowls (27). There are inlet nozzles (receiving drives) with guides on the body. These drives spread row grain over receiving sieve frames of each sections. To the nozzles (5) and to the nozzles of the receiving devices are attached to the receiving sleeves (16). The outlet sleeves (11) attached to the nozzles (17, 30) which mounted to the body bottom and floor nozzles. There are receiving boxes (2) mounted to the receiving devices. The receiving devices are hung under the celling frame by holders (13) and rods (14). Air ducts, aspirating systems and gravity of product supply are mounted to the receiving boxes.

The support frame (21) is solid mechanical welded construction. The sections and side panel, bottom, body roof, lower and upper bearing units of the balancing mechanism (6) are mounted to the support frame. The balancing mechanism let the plansifter move. The support frame is made of wooden blocks. There are 4 cells of this frame. There are inserts in the frame cells. The inserts are box with bottom of sieves. Bow walls don't have any holes. They are needed to protect frame wood parts from wear. The cleaners are bolls with diameters Ø 25 mm. The cleaners are designed for sieves cleaning.

The balancing mechanism is shown in Drawings 1, 4, 3.

Chart 2. – The kinematic characteristics of plansifter

| Kind of grain |

Name of technological process |

kinematic characteristics |

№ scheme |

Product name |

| patency |

exit |

| R., mm |

n, RPM |

1 |

2 |

3 |

1 |

2 |

3 |

| Rice |

Separation of hulling product |

25 |

190 |

4 |

Bran flour |

|

|

Mix of kernel and grain |

Mix of kernel and grain |

kernel |

| Separation of shelling products |

25 |

230 |

4 |

crushed |

|

|

cereal |

cereal |

Mix of cereal and crushed cereal |

| Bran flour control |

25 |

230 |

3 |

Bran flour |

Bran flour |

crushed |

cereal |

|

|

| Millet |

Cleaning from large and light impurities |

26 |

220 |

1 |

Light impurities |

Cleaned grain |

|

Large impurities |

|

|

| Sorting by size |

26 |

180 |

1 |

Small grain |

Small grain |

|

Large grain |

|

|

| Millet control |

26 |

190 |

3 |

Crushed and bran flour |

Crushed and bran flour |

millet |

Large impurities |

|

|

| Barley |

Sorting of millet groats |

25 |

190 |

2 |

Bran flour |

|

|

|

Whole grain |

Crushed grain |

| Sorting of crushed product |

25 |

190 |

4 |

Bran flour |

|

|

grain |

Large cereal |

Small cereal |

| Sorting of barley cereal |

25 |

190 |

4 |

Bran flour |

|

|

grain |

Large cereal |

Small cereal |

| Sorting of pearl barley cereal (pre-sorting) |

25 |

190 |

1 |

Bran flour |

|

|

shelling |

Cereal No1 |

Mix of cereal number besides No1 |

| Sorting of cereal by numbers 1, 2, 3 |

25 |

190 |

2 |

Small cereal |

Small cereal |

|

Finish product |

|

|

| Sorting of cereal by numbers 4, 5 |

25 |

220 |

3 |

Bran flour |

Small cereal |

|

Finish product |

|

|

| Bran flour control |

25 |

230 |

3 |

Bran flour |

Bran flour |

Small cereal |

Large cereal |

|

|

| Oats |

Cereal control |

25 |

190 |

3 |

Crushed cereal and bran flour |

Crushed cereal and bran flour |

cereal |

Large impurities |

|

|

| Buckwheat |

Sorting of fraction before hulling |

23 |

190 |

1 |

Small grain |

|

Basic fraction |

Difficultly-separable impurities |

|

|

| Separation of hulling product |

26 |

190 |

2 |

patency |

|

|

other |

kernel |

|

| Buckwheat groats control |

26 |

190 |

2а |

patency |

|

|

Difficultly-separable impurities |

cereal |

|

| Patency control |

26 |

220 |

3 |

Bran flour |

Small patency |

Large patency |

cereal |

|

|

| Husk control |

26 |

220 |

4 |

Bran flour |

|

|

husk |

husk |

patency |

The mechanism let to manage of vibrations radius of plansifter. It does this by weight change of balancer due to installing or dismantling of replaceable cargo 2, 3. Number of balancing mechanism rotations is regulated by pulleys of plansifter drive (chart 2.2).

Product use:

When the plansifter work hard (operating), special attention should be paid to:

- Uniform loading of all sections;

- Body tightness, preventing loosening of threaded connections and dusting of products;

- Absence of fraction mixing;

- Condition of all moving units and parts, quietness work;

- Sieves cleaning;

- Aspiration efficiency, preventing fogging of the walls inside the body at temperatures below 15°C.

Efficiency of separation and coefficient of involving of patency fraction depend on property of the original product and load. Efficiency of separation and coefficient of involving of patency fraction could be regulated by changes of plansifter kinematic parameters, namely frequency and amplitude of vibrations. Adjusting of the optimal kinematic mode of the plansifter is for the best technological effect. Depending on raw product and on the system of technological process (Chart 2), there are optimal plansifter kinematic parameters. Amplitude of circular vibrations of the plansifter adjusted owing to replaceable weights on the balancer. In chat 2.1 you can see dependence of the radius (1/2 amplitude) of vibrations of the plansifter under load on the mass of removable weights.

Chart 2.1.

| Options of weight set |

Position of additional weights |

Weight of one of it, kg |

Total amount of additional weights |

Weight of all additional weights, kg |

Total amount of balance weight, kg |

Body vibration radius, mm |

| 1 |

1 |

2,3 |

8 |

18,4 |

236 |

22,6 |

| 2 |

1 |

2,3 |

8 |

38,4 |

256 |

25,1 |

| 2 |

2,5 |

8 |

38,4 |

256 |

25,1 |

| 3 |

1 |

2,3 |

8 |

48,4 |

266 |

26,3 |

| 2 |

2,5 |

8 |

48,4 |

266 |

26,3 |

| 3 |

1,28 |

8 |

48,4 |

266 |

26,3 |

| 4 |

1 |

2,3 |

8 |

68,4 |

286 |

28,0 |

| 2 |

2,5 |

8 |

68,4 |

286 |

28,0 |

| 3 |

1,28 |

8 |

68,4 |

286 |

28,0 |

| 4 |

4,9 |

4 |

68,4 |

286 |

28,0 |

Video: