Purpose:

Universal grain-cleaning separator БСХ-200 is designed for pre-cleaning (elevator mode), cleaning and final cleaning (mill mode) from the impurities, different from it in width, thickness and aerodynamic properties.

Due to its numerous settings, universal grain-cleaning separator БСХ-200 is designed for both primary cleaning (elevator mode) and final cleaning (mill mode) of a grain heap of spikes (wheat, rye, oats, etc.), cereals and leguminous crops, industrial and oil crops, grass seeds from light, large and small, weed and grain impurities, differing in geometric dimensions and aerodynamic properties, which are separated by an air flow and sieves, in order to bring the content of impurities in the harvested grain to the indicators regulated by the Rules for conducting technological processes on elevators, mills, groats factories, feed mills and other regulatory documents.

Grain-cleaning separator БСХ-200 has been produced since 2010 and successfully operated in Ukraine, the Russian Federation, the Republic of Belarus, the Republic of Moldova, the Republic of Serbia, the Kyrgyz Republic, the Republic of Latvia, the Republic of Lithuania.

The separators are intended for use as grain cleaning machines at agricultural enterprises, including at explosive production facilities. The separator is used as part of grain currents, in grain preparation departments at granaries, elevators, at flour mills, malt houses, feed mills. etc.

Separators are manufactured according to the 3rd category of State Standard (IEC 60721-2-1; IEC 60068-1) in climatic version "У" for the domestic market and export to countries with a temperate climate. At the same time the separators must operate reliably in operating modes at temperatures from minus 10 to plus 40 °С, relative humidity of 80% at an average annual temperature of plus 15 °С, atmospheric pressure from 650 to 800 mm Hg. (86.6 ÷ 106.7 kPa). When using special greases, the separator starts up and operates reliably at temperatures from minus 30 °С

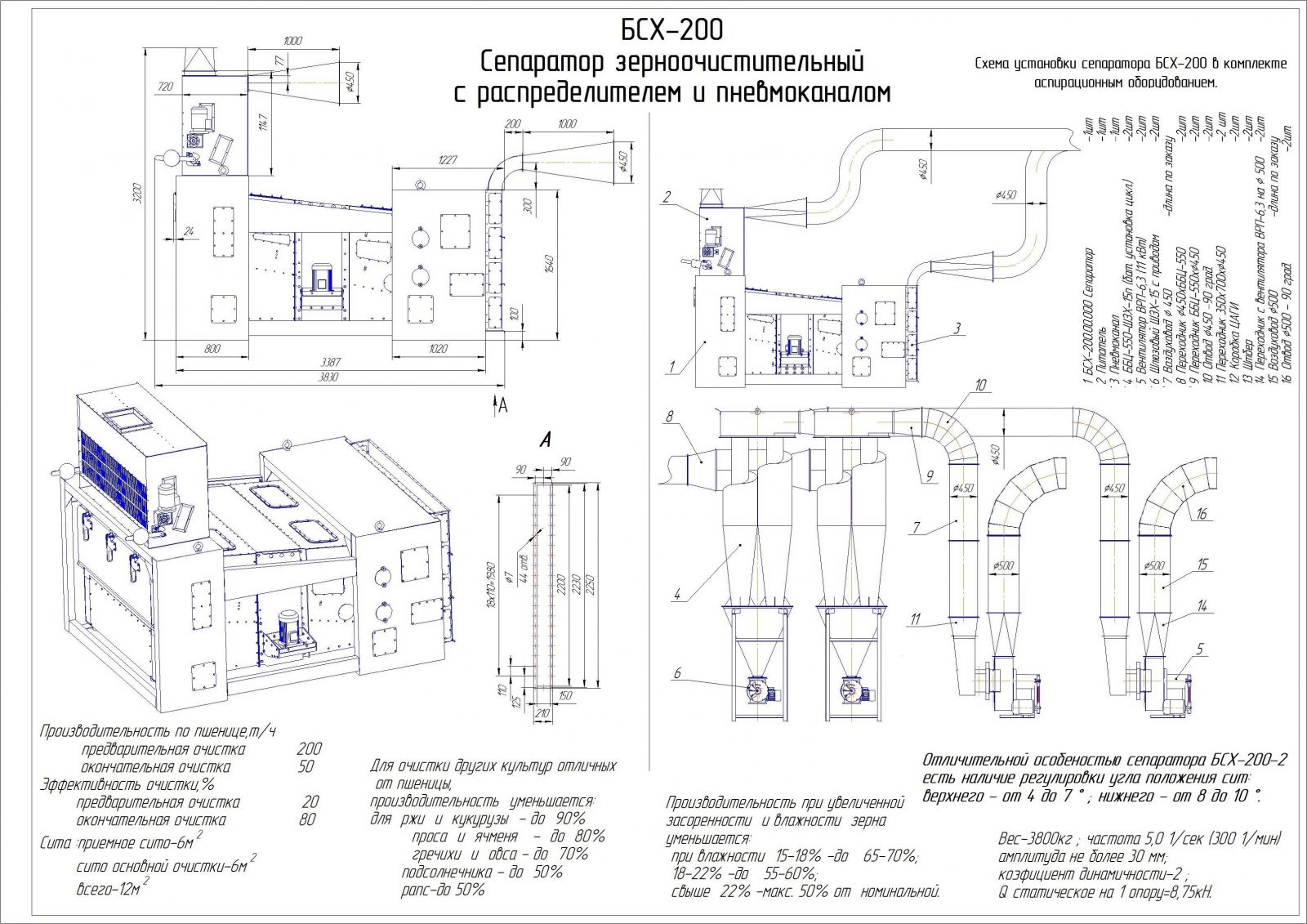

Specifications:

| Parameters |

БСХ-200 |

| 1. *Capacity, t/h: |

|

| - pre-cleaning (elevator mode) |

200 |

| - final cleaning (mill mode) for wheat with humidity max. 15% and with the impurities max. 3% |

50 |

| 2. Efficiency of cleaning, %, min: |

|

| - pre-cleaning |

20 |

| - final cleaning for wheat max. 15% and with the impurities max. 3% |

80 |

| 3. Installed power, kWt, max |

2,95 |

| 4. Air flow, m3/h, max: |

17 000 |

| - pneumatic separation before cleaning machine |

8 500 |

| - pneumatic separation after cleaning machine |

8 500 |

| 5. Circular oscillations rate of sieve body, С-1 (number per minute) |

5,0 (300) |

| 6. Circular oscillations radius of body, mm, max |

14 ± 2 |

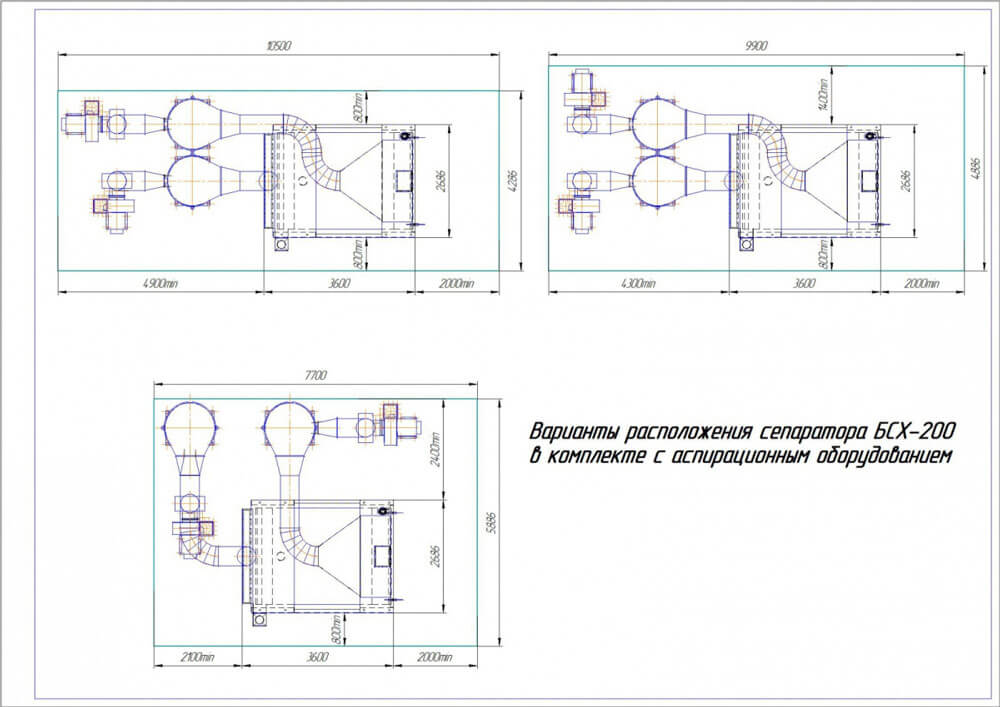

| 7. Dimensions, mm, max., of cleaning machine (without cyclone): |

|

| - length |

3 830 |

| - width |

3 110 |

| - height |

2 950 |

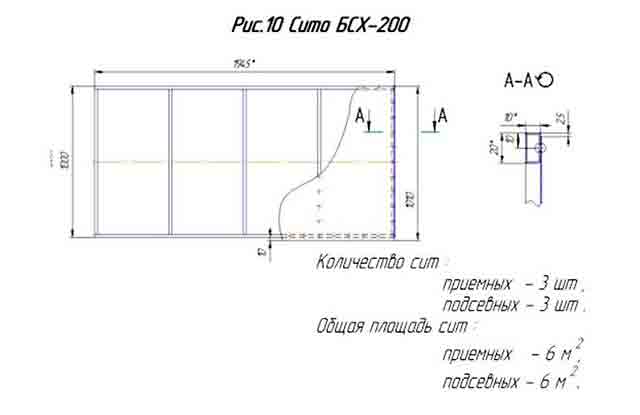

| 8. Area of sieves (sieving/receiving), m2 |

12 (6/6) |

| 9. Quantity of grates (sieving/receiving), pcs. |

6 (3/3) |

| 10. Total area, m2 |

15,00 |

| 10. Weight, kg, max |

3 850 |

| 11. Service term, years |

8 |

Note.*

The technical productivity indicated in line 1 refers to the purification of the feedstock - wheat with a bulk density of 760 kg/m3 and the content of impurities (seeds of weeds and cultivated plants):

- for preliminary cleaning with a trash content of up to 15% at a humidity of up to 20%;

- for secondary cleaning with a trash content of up to 3% at a moisture content of up to 15%.

With an increase in the above norms of contamination and moisture content of the starting material, the technical performance of the separators decreases by 2% for each percentage increase in contamination and by 5% for each percentage increase in moisture content.

For cleaning crops other than wheat, productivity is reduced as follows:

- for rye and corn - up to 90%;

- for millet and barley - up to 80%;

- for buckwheat and oats - up to 70%;

- for sunflower - up to 50% of the nominal.

Distinctive features of БСХ-200 from analogs according to the technological scheme are following:

- The presence of ability to adjust the angles of inclination of the upper and lower sieves makes it possible to optimally adjust the separator depending on the cleaning tasks (elevator or mill mode) the type of grain and its condition (trash and moisture).

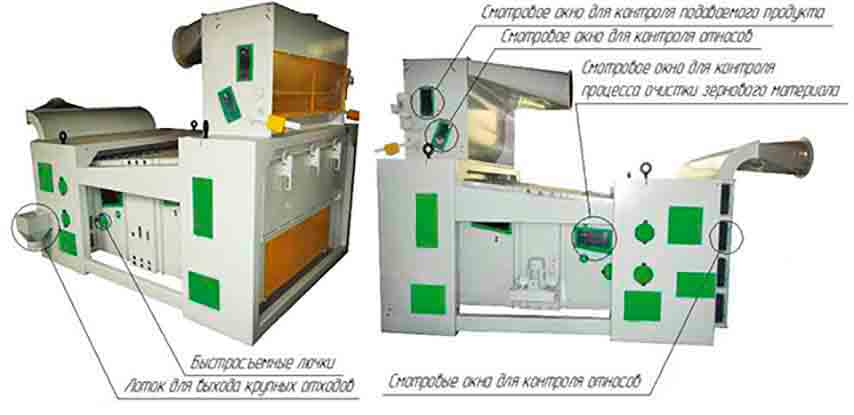

- The presence of inspection hatches on the sidewalls and the roof of the body for adjusting the feeder counterweights and visual control of the cleaning process of grain material.

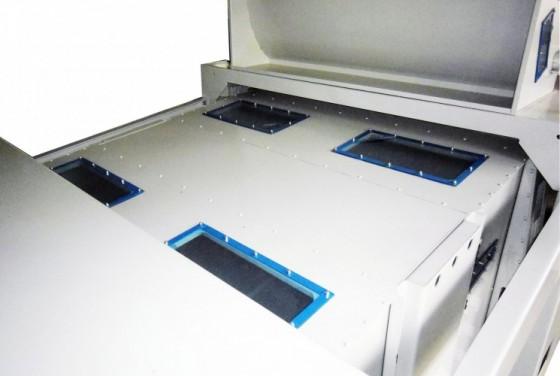

- Optimum ratio of tray mesh and sieve cleaner (rubber ball) is for more efficient cleaning of sieves from trapped particles.

- There is the possibility of quick (up to 30 minute ) replacement of sieves when it is needed to change from culture to culture, with cleaning the machine body, without removing trays with cleaners from the car.

- The presence of quick-release hatches on the sidewalls of the body and the cage frame for access when cleaning and maintaining the machine.

- There are the possibility of rearranging the chute for discharging large waste to the left or right side and the possibility of rearranging the electric motor of the body drive to the left or right side, which makes it possible to adapt the separator to the characteristics of a particular room, especially in the case of modernization (improvement) of existing lines.

- Equipped with a special feeder at the entrance to the machine, which allows you to guarantee the distribution of the product flow across the width of the entrance to the sieves, while there is no need to use a preliminary hopper.

- It is easy installation of the separator directly in placement.

Design and operation:

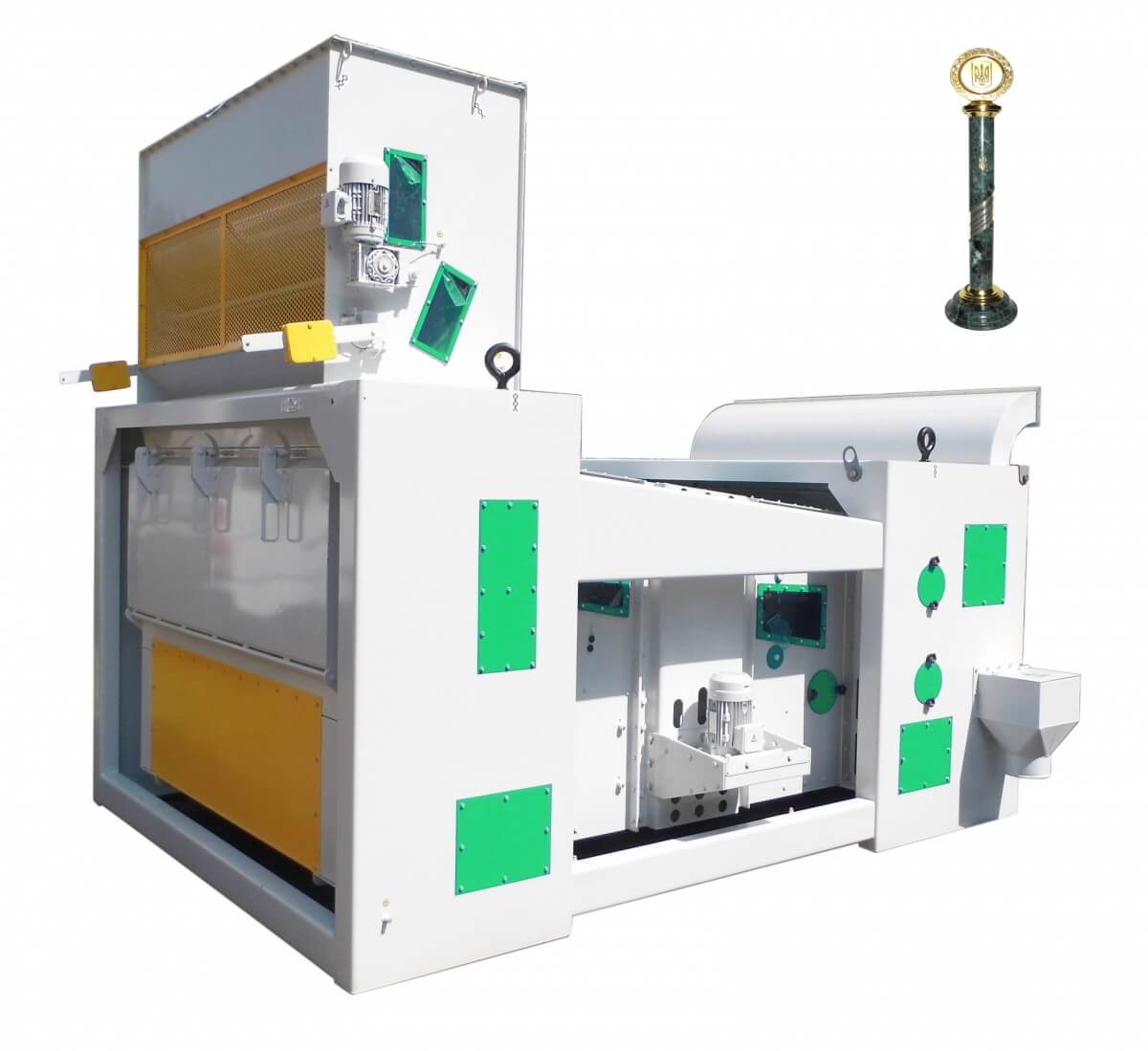

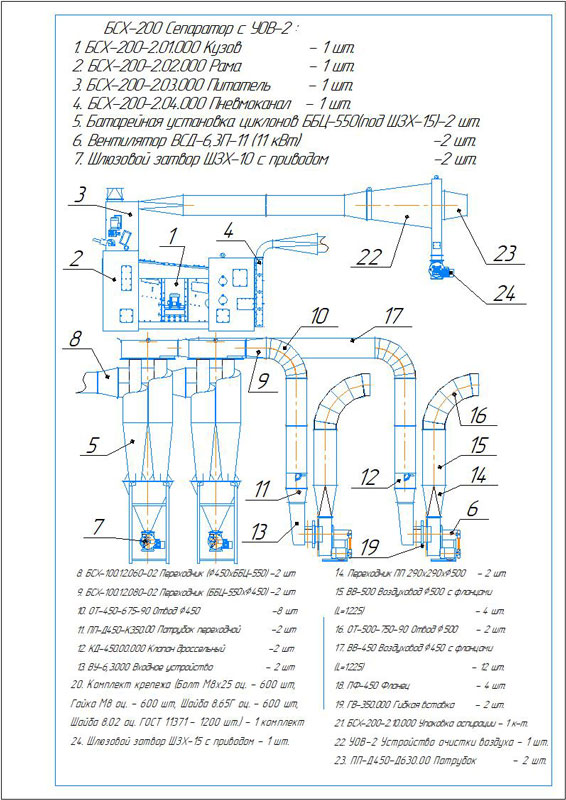

Grain cleaning separator БСХ-200 (Drawing 1) consists of the following units: frame (1), body (2) with sieve frames, feeder (3), pneumatic channel (4).

The body is suspended from the frame on flexible suspensions. The grating frames are inserted into the body along the guides fixed on the sidewalls of the body and fixed motionlessly with screws. The sieves are mounted on the sieve frames, riveted to separate frames. The design of the separator provides for the adjustment of the tilt angles of the sieve frames: the upper one from 4° to 7°, the lower one from 8° to 10.

Large installation angles increase the speed of grain movement on the sieves and provide greater productivity. Shallow angles naturally reduce speed and productivity but increase the likelihood of particles passing through the holes as a result the separation efficiency of impurities increases. In addition small installation angles allow more efficient cleaning of small grains and oilseeds (rapeseed, mustard, sunflower, soybeans). The sieve frames are divided by longitudinal and transverse partitions into cells where rubber balls are placed, designed to clean the sieves from stuck particles.

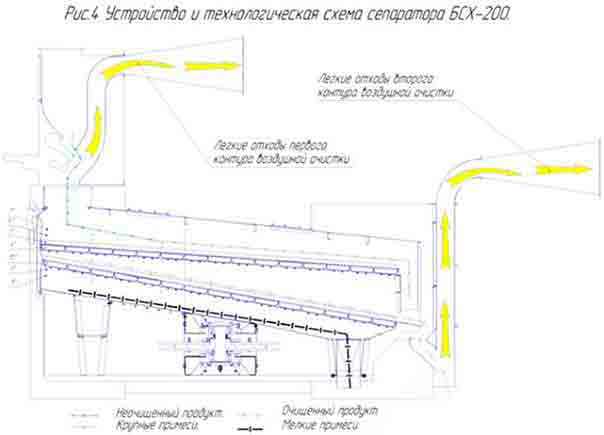

The separator body is driven from an electric motor by a V-belt transmission. The drive motor is mounted on brackets on the left side of the body (on request, the engine can be mounted on the right side of the body). The belts are tensioned by moving the sub-engine plate along the grooves using tensioning screws. Initially the grain heap from the gravity flow enters the feeder where it is distributed over the entire width of the machine and is pre-cleaned by air flow from light impurities. At the top, in the front part of the body, there is an inlet pipe (Pic. 4), which serves to supply the sorted product from the feeder to the body.

The separator body makes circular movements, under the influence of it the product moves along the sieve and is sorted. Large impurities are removed from the separator through a tray (Pic. 4), and a mixture of grain with small impurities passes through the sorting sieve to the lower sieve frame. After have been waking up through the under-sowing sieve small impurities fall on the bottom of the separator and then are removed from the machine through a tray.

The cleaned grain on sieves from large and small impurities enters the inlet of the pneumatic channel. In the pneumatic channel of the separator the grain is blown again by the air flow of the second circuit thereby further cleaning it from the remaining light impurities.

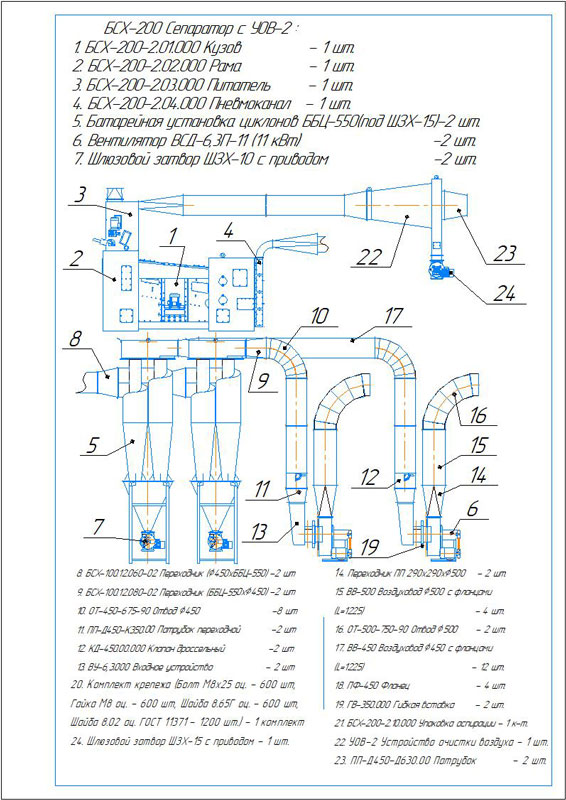

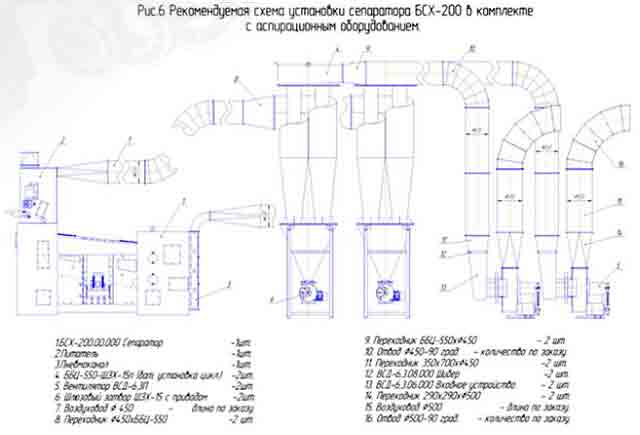

The recommended installation diagram of the separator complete with aspiration equipment is shown in Drawing 6.

Separators can operate in an elevator (pre-cleaning product), as well as in a mill (final cleaning) modes, depending on the types of sieves used. To clean the grain from impurities that differ from it in size, the separator can use sieves with round, elongated or triangular holes corresponding to the shape and size of the grain of the main crop and trash impurities.

Attention! The selection of sieves in order to obtain the required degree of purification is carried out by the consumer at the place of operation of the separator, depending on the original product and its properties (moisture, contamination, fractional composition, etc.).