26.11.2025

Experienced grain processors know that to achieve impeccable product quality, it is necessary to ensure that modern technological equipment is available in production facilities in a timely basis. The main tasks of cereal, flake and flour producers: high quality of the final product, the possibility of expanding the assortment, effective output indicators of finished products with minimal electricity consumption.

In this article, we will discuss the top five current high-quality grain processing equipment.

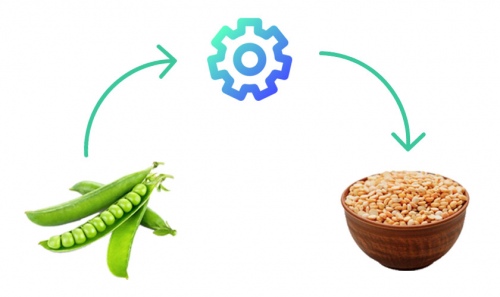

1. Peas shelling machine (manufacturer's name - Impact dehuller СІМО ЦШС-3 (02)). This machine has no analogues, which is why it has become the perfect and indispensable equipment for the production of pea groats. The first machine was manufactured in 2016. Over the period of nine years, the pea shelling machine has been modernised twice, and approximately one hundred units of equipment have been delivered and commissioned at grain processing mills both in Ukraine and abroad. It is rightly considered the most efficient machine for processing peas into groats with a very high yield of finished product.

Advantages:

- Simultaneous peeling of peas and splitting them into two halves (cotyledons);

- Yield of finished groats (whole halves) - 88 - 90%;

- High quality of the processed product - peas halves have smooth, unscratched edges, surfaces without scrapes, and the product retains its bright natural colour.

2. Abrasive dehuller for legumes ЛАБ-1,5. This is a new exclusive machine of 2024, which designed for dehulling of the following legumes: lentils, chickpeas, lupins, soybean and others.

Advantages:

- Provides yield of finished product of 85%;

- A unique machine specially designed to process the legumes that are becoming more popular in the modern diet;

- Perfectly fits into a universal grain and legume processing plant.

3. Steamer ПЗ-1. Steamers play kea role in hydrothermal treatment of grain. This treatment of grain with excess pressure of saturated steam improves the technological properties of the grain, creates optimal conditions for grain processing and for producing groats that meet the highest nutritional requirements. The use of hydrothermal processing allows for the production of quick-cooking cereals and increases the yield of finished products. It used in the flour and cereal industry for processing buckwheat, wheat, barley, oats, corn, rice, peas.

Advantages:

- Leads to increased core strength and easier separation from shells;

- Using of steam treatment of grain leads to an increase in the yield of groats by 5 to 12% and improves its consumer properties;

- The nutritional value of the product and its stability during storage are increased.

4. Roll huller СГР-600М. Roll hullers СГР-400, СГР-600 and СГР-600М are used for hulling buckwheat and millet at grain processing mills and enterprises. Hulling as a grain processing method is one of the main operations in cereal product technology.

Advantages:

- The output of finished products (cereals) and their quality are significantly increased after the husking process using such machines;

- Ideal for grain crops whose husks are not joined to the kernel (millet, buckwheat), making them indispensable in the production of millet and buckwheat groats.

5. Flaking mill ПС. Flaking mills ПС-400 и ПС-600 are used in cereal flakes producing lines. Ideal for flattening cereals and hulled grains while manufacturing oatmeal, buckwheat, pearl barley, finely ground barley, corn, wheat, rice and other flakes. Upgraded flaking mill ПС-600М was made in 2007.

Advantages:

- Relatively low metal content in the machine structure, with working parts made of bleached cast iron;

- Reduced noise during operation;

- Optimal working gap between flattening rollers is 0,05 mm;

- The rollers have an extended wear-resistant zone, which allows for surface renovation without compromising performance characteristics;

- Improved heat removal process from the surface of the working rollers and cooling of the entire roller as a whole;

- The use of a hydraulic puller is permissible, and the process of disassembling and assembling the machine during major repairs has been significantly improved;

- The machine is driven by two electric motors, which completely eliminates inter-roller transmission with its undesirable consequences;

- An automatic control panel using a microprocessor allows the human factor to be eliminated.

Competent grain processors focus on quality, guarantees and service possibilities when choosing equipment. It is ideal combination that guarantees stable production and high quality of the finished product. Modern technologies and equipment allow to optimise all stages: from primary cleaning and drying to deep processing, as well as reducing costs and increasing the competitiveness of the enterprise.