31.01.2020

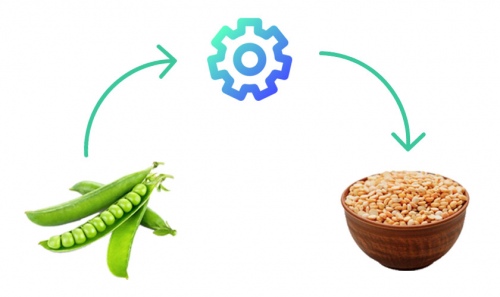

Beginning of 2020. It's new beginnings and initiatives. Clients often refer to us about cereal processing line foundation as a successful business creating. Now this theme is so actual. And we decided to explain clear algorithm to build cereal mill step by step for gain ground.

The creation of the groats mill is based on the main four "pillars":

- Company`s mission. Which product do you want to produce (capacity, grade, crops or flakes, which cereal exactly).

- How to choose the right manufacturing area for mill creation.

- The choice of technological equipment taking into account several mandatory technological processes for a cereal plant.

- The choice of supplier of raw materials. The raw materials must be of good quality, otherwise it will affect the quality of the cereal (finish product).

You also should take into account the grain storage rules, cereal requirements, finish product packaging rules, full compliance of the production process with standards and, of course, quality of raw materials.

Behind each of these points is the main word - professionalism. Our professional team of “AGRO-SIMO-MASHBUD” works to help customers. We help to follow up on your needs and inquiries. Our specialists will find the best solution for you from design stage to start-up of mill.

We`ll tell you in detail about some basic points.

Cereal Mill or Aggregate cereal mini factory

If you have a decision about kind of cereal and flakes you want to produce, you can step forward. In the next step you should know what productivity do you need, what production volume are you interested in at the stage of launching a business project, as well as at the stage of the next 5 years. A professional technologist will ask you such a question. Aggregate cereal mini factory provides productivity up to 22 tons of processed grain per day. While industry cereal mills provide from 24 to 250 t/d. This productivity depends on customer`s requests. As a rule, cereal mills are located in three- or five-floor buildings.

Aggregate cereal mini factory is a special small-sized installation, which is mounted on a compact metal structure and is located in a one-floor building (a hangar up to 6 m high). Basically, such building is both a warehouse of raw materials and a warehouse of finished products.

Industry cereal mills is a complex that includes a complete set of industrial specialized equipment. It consists all machines from preliminary cleaning machines to finish product control machines (for example, color sorters etc.) Industry cereal mills have own floor storages and elevator storages for 2-6 months of work. They have also storages for finish product up to 1.5 storing months. At such mills, over time it is easier to modernize production with increased productivity and yield of finish product by replacing or improving parts of the equipment. At the same time, aggregate cereal mini factory have advantages, namely, low cost, small sizes and small quantity of workers. These factories are good for starting of business.

The choose of manufacturing area for cereal mills

You should take notice of logistical costs. The costs are significant part of total expenses. Thus, Cereal mills should be brought as close as possible to sources of raw materials and to channels of distribution. Availability of human resources is important detail for choose of manufacturing area too.

Let`s add up this information. It`s very important to calculate technological line and list of equipment. It`s very important to understand you will have investment return if you have high quality equipment.

Don’t save many for supply base. Keep a brand of quality product and strive for better performance!

Make informed choices when you are purchasing grain processing equipment.

Therefore, together with competent management and marketing, your project will pay off in 2 - 3 years.