27.05.2025

Today, professional media platforms are more and more frequently mentioning that corn (maize) is the main raw material in the global bioethanol production market. And this is due to the high starch content of this crop. There is also high consumer value of corn products such as corn groats, flour and corn oil.

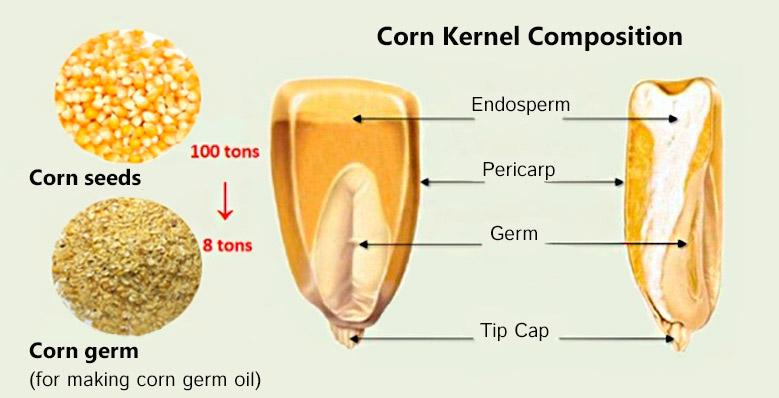

The first stages of maize processing into different products are almost identical - after cleaning from impurities, maize is grinded in degerminators for further extraction of maize germ. The content of germ ranges from 8 to 14%, depending on the variety of maize. The maize germ oil content, depending on the place of origin, grade and climatic conditions, can be 24-30 per cent.

The germ extraction is due to the fact that during the processing of maize into bioethanol, germ fat significantly reduces the efficiency of fermentation of complicated maize starch molecules. Thus, because of the above, the percentage of bioethanol output may decrease, and when processed into cereals and flour, it reduces their organoleptic properties and storage life due to rancidity (oxidation, damage and loss of quality).

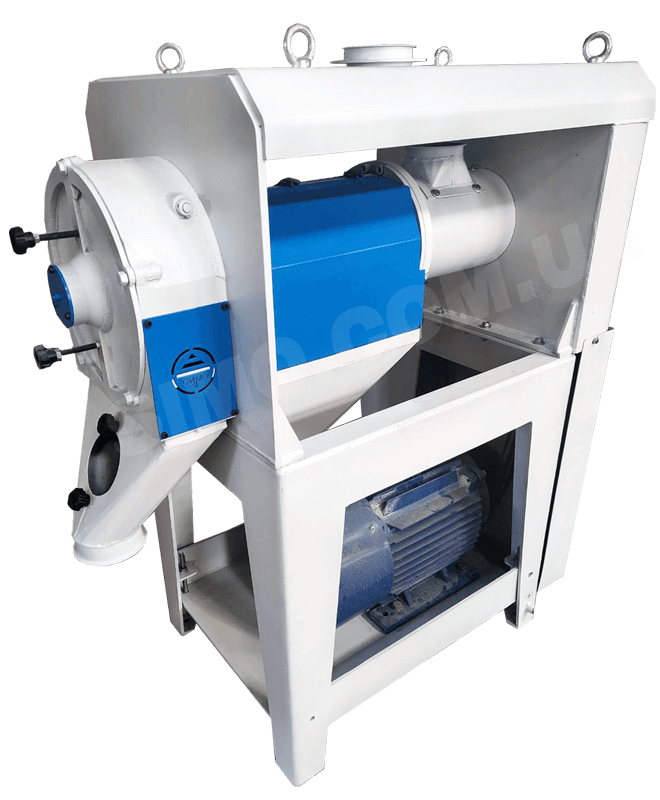

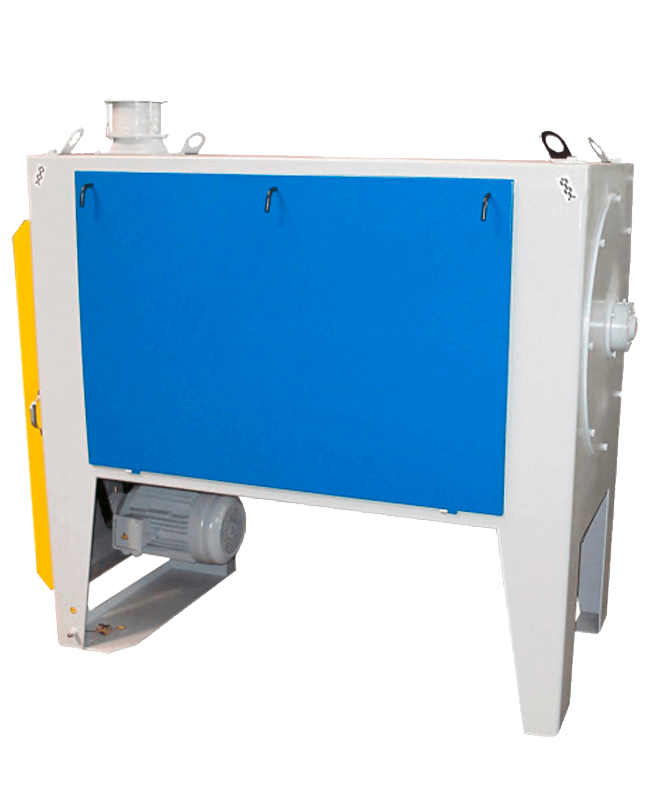

Our company propose two variants of corn processing technologies – two variants of degerminators to germ separation. At productivity up to 60 t/day of maize grain we offer a reduced processing scheme with the use of the Degerminator ДС-2. The use of this machine makes it possible to break the maize kernel by high pressing forces and, directly in the dehairminator itself, to extrude the crushed germ together with the peripheral parts, the tip and bran flour. Such a mixture of ground germ and bran flour can be used for feed purposes only or as an ingredient in the preparation of feedstuff.

At productivity more than 80 tonnes per day of corn grain we offer a complex technological scheme of processing with the use of Degerminators of MП type with different productivity - from 2,5 to 6 tonnes per hour. The use of this type of degerminators allows to effectively control the degree of corn grinding (regulate the size of the produced fractions). However, this keeps the germ in a mixture of milled maize kernels of different fractional compositions. And for its effective extraction, the maize grinding products are fractionated in the plansifter into several fractions, and each of them is sent to the table separator, where the pure germ is extracted. Depending on the variety of maize, between 7 and 10 per cent of the germ can be excreted like that.

The isolated germ is used to produce a very valuable corn oil. This oil is rich in vitamins A, F, E and unsaturated fatty acids. It is also important that corn oil does not form carcinogenic substances when heated, it does not smoke, foam or burn during cooking! The temperature of oil burning is 232 °C. For example, sunflower oil starts to smoke and actively share carcinogens already at 107 °C of heat. Corn oil also contains phytosterols (phytosteroids), which help reduce blood cholesterol levels.

So, corn oil is getting more and more recognition in the international market. Therefore, processing maize into oil becomes a more favourable strategy than exporting maize grain as a raw product. Let us take in account an example of maize grain exports from Ukraine in recent years. China has been the main importer of Ukrainian corn for the last few years. Therefore, China imported more than 30 per cent of all Ukrainian corn until 2022. Romania and Spain were also active importers of this crop. But due to the military actions in Ukraine and the blocking of sea ways, exports of grain and, accordingly, maize have significantly decreased. Moreover, China has started actively buying Brazilian corn. By the way, from 6 June this year, the EU will significantly increase import taxes on Ukrainian grain and stop special trade privileges (duty-free trade regime with transitional rules), although the sides are working constructively to reach a renewed long-term free trade solution and the European Commission will implement a transitional regulatory measure following the expiration of Ukraine’s current duty-free trade arrangement. Ukrainian corn export purchase prices are expected to fall and corn exports continue to slow down! Therefore, one of the main questions facing the agricultural industry is the choice between exporting raw materials and processing them into value-added final materials. And in the case of maize, the conversion (processing) of this crop into bioethanol, oil and other co-products such as bioethanol waste biogas, alcoholic bard, opens up many new opportunities to increase economic efficiency in grain processing.

You can get detailed consultations on germ extraction, bioethanol production, oil production technology and other related products from corn from experienced specialists-technologists of SIC «AGRO-SIMO-MASHBUD”.