Purpose:

Dosing scales ДВС-301-1000-1-П-1 is designed to prepack bulk products into bags of Big-Bag type and with display indication of:

- the current value of the mass of material filling the container, kg;

- accruing totals in tonnes, and/or number of doses in units;

- a range of supporting parameters by keypad call.

The dosing scales completed with bags exit system from the section of dosing. The machine also completed with automatic strap reset.

Specifications:

| Parameter |

ДВС-301-1000/2000-1-П-1 |

| 1. Productivity, bags/hour |

Up to 30* |

| 2. Maximum limit of weighing (НПД), kg |

500 - 1 000 / 2 000 |

| 3. Minimum limit of dosing (НмПД), kg |

500 |

| 4. Set time for steady-state operation mode, min. |

Up to 5 |

| 5. Measuring and displaying time, s |

Up to 0,1 - 1,0 |

| 6. Sensitivity threshold of the weighing device, max., kg |

0,28 / 0,7 |

| 7. Dosing scales managing |

Electric-pneumatic and electro-mechanical |

| 8. Tolerance limits for deviations of the actual dose mass from the average value, over the entire dose range (values in percent should be calculated from the nominal value of the dose mass), %:: |

|

| - during initial verification or calibration* |

± 0,1; ± 0,25* |

| - during initial verification or calibration while operation* |

± 0,2; ± 0,5* |

| 9. Accuracy grade of the Dosing scales as per state standard ГОСТ 10223-97 |

0,2; 0,5* |

| 10. AC current power supply, V/Hz |

(220 ± 22/33) / (50 ± 1) |

| 11. Power consumption (without actuation mechanisms), max., VА |

25 |

| 12. Total power consumption of the drive, max., VA |

3 500 |

| 13. Compressed air pressure, MPа |

(0,6 ± 0,06) |

| 14. Compressed air consumption, max. |

0,1 m3/hour |

| 15. Ambient temperature, °С (sub-zero temperatures are acceptable when the air in the pneumatic system is dry) |

from - 10 to + 45 |

| 16. Humidity, % |

Up to 95 if t = 35 °С |

| 17. Degree of protection against environmental exposure (as per state standards ГОСТ 14254-96) of: |

|

| - weighing processor ПВ-310 |

IP 65 |

| - load receiving device |

IP 68 |

| 18. Dimensions (LхWхH), mm |

|

| - weighing device |

2030 х 1975 х 3595 |

| - storage conveyor |

3049 х 1750 х 775 |

| 19. Weight, kg |

|

| - weighing device |

910 |

| - storage conveyor |

1126 |

| 20. Total weight, kg |

2036 |

| 21. Full average life of the dosing scales, min |

10 years |

* — The capacity depends on the physical and mechanical properties of the material to be weighted and processed.

Design of Dosing scales:

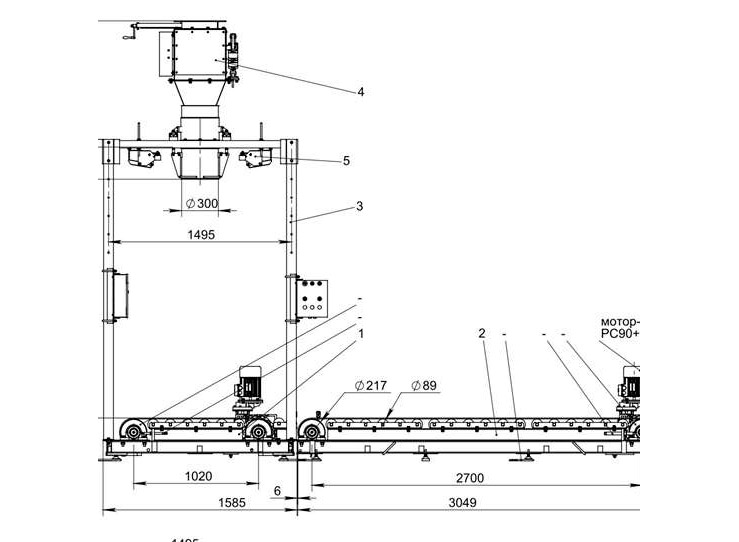

Dosing scales – semi-automatic discrete unit. It consists of device of product supply (УПМ), weighing device (ВУ), load receiving device (ГПУ), pneumatic system (ПС), automatic device of weighing (dosing) control (УУ), bag opening (inflating) system. The weighing processor takes care of all dosing control, except for bag fixing and inflation operations.

Dosing scales includes the following components:

- device of product supply (УПМ) – Image 1, with section gate valve. The gate valve is moved by pneumatic cylinder with two positions “Closed”, “Roughly” (basic supplying of the product) and “Exactly” (filling up the product to the set dose with a slow low flow). There are pneumatic cabinet, two pneumatic switchgears and fan of bag inflating on the body of product supply device. The pneumatic cabinet has air treatment station.

There is the hole (funnel) at the lower part of the product supply device. The funnel connects with the neck of weighing part of the machine. There is the nozzle for dusted air aspiration on the neck.

- weighing device (ВУ) is a platform with four load-receiving devices with strain gauges. Four racks are fastened to the platform. The frame is on the racks. The frame is adjusted by its height as per platform due to guide bolt М12 х 100. There are four devices for hanging the straps of the Big-Bag are adjusted on the frame by device's height. Loading device (Image 1) is fastened on the frame too. The neck of the loading device is attached to the neck of the bag due to a pneumatic clamp. An equalisation box is installed on the platform for parallel connection and alignment of the stain gauges' angle loads.

- automatic device of weighing control (УУ) is the combination of the electronic elements of the weighing device and the pneumatic system, which managed by weighing processor ПВ-310. You can see the neck of the dosing scales with the pneumatic clamp of Big-Bag neck on Image 2.

The weighing platform conveyor together with the storage and outfeed (discharge) conveyor with photo sensors form a bag conveying system. It is used to remove the bags from the dosing and weighing area, to transport them further away from the filling station to the storage area. The discharge conveyor can hold two Big-Bag containers at the same time.

Operating procedure:

Pallet is installed on the weighing platform. BIG-BAG loops are attached to the strap holders. The neck of BIG-BAG is attached to the neck of the Dosing scales, which installed on the frame. A fan is switched on from the control station and blows up the BIG-BAG. You should press the button “Tare” of the weighing processor to remember the tare weight (the processor display will be reset to zero). The pneumatic drive fully opens the gate by "Start" button and the material from the storage hopper flows into the BIG-BAG.

When the set point is reached "roughly", the pneumatic drive sets the gate valve to the "exactly" position and the material is refilled to the set dose value. The gate valve closes and the display shows the dose weight and the amount of material dispensed in cumulative total. After the container is full, the bag straps are automatically dropped and the conveyor drives are activated. The combined movement of the conveyors ensures that the container moves from the weighing device to the storage conveyor and to the discharge point. Photo sensors ensure that the belt conveyor is not switched on and that no new filling is started until the loader has cleared the belt conveyor. Then the cycle repeats.

The weighing processor ПВ-310 fully manages dosing (weighing) process, the measuring and controlling the weight of the material in the bag. The weighing processor contains an interface in Russian and English.

Product composition:

| Number |

Composition |

Quantity, pcs. |

| 1. |

Weighing platform with drive conveyor |

1 |

| 2. |

Supporting racks |

4 |

| 3. |

Frame with the neck and pneumatic clamp of the bag |

1 |

| 4. |

Product supply device |

1 |

| 5. |

Bag strap release device |

1 |

| 5. |

Strain gauges |

1 |

| 6. |

Strain gauges |

4 |

| 7. |

Fan for bag inflating |

1 |

| 8. |

Gate |

1 |

| 9. |

Diverting conveyor with gearmotor |

1 |

| 10. |

Pneumatic equipment set |

1 |

| 11. |

Pneumatic cabinet |

1 |

| 12. |

Electric cabinet |

1 |

| 13. |

Weighing processor |

1 |

| 14. |

Documentation set |

1 |

The machine has climatic execution “УХЛ3.1” in accordance with state standards ГОСТ 15150-69, but as per the following conditions: at minus 10 °C to 45 °C and an upper relative humidity of 95% at 35 °C. Dosing scales have output to external recording devices over the standard RS-485 interface.