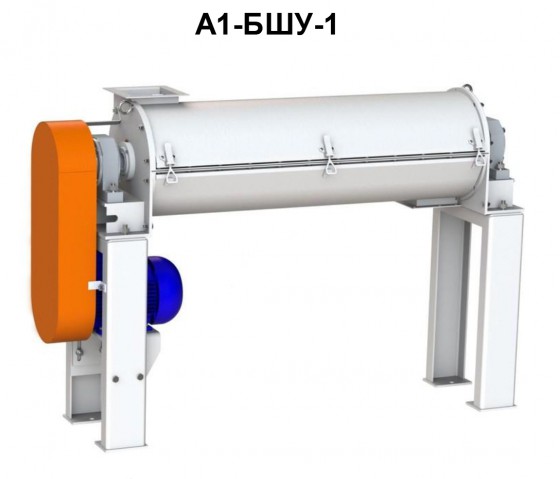

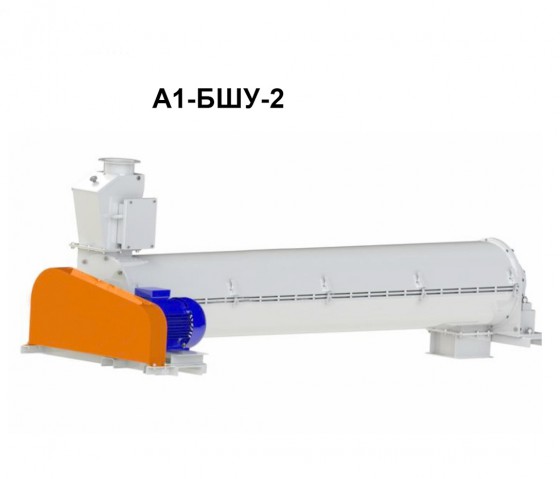

Purpose:

Dampener of grain А1-БШУ-1 is designed to increase the level of moisture in wheat grain in preparation for grinding. Dampener А1-БШУ-2 is designed for intensive moistening of wheat grain in preparation for grinding. The machine is manufactured in climatic design УХЛ-4 (products for use in areas with a temperate and cold climate with placement category 4 (in rooms with artificially controlled climatic conditions) State Standards 15150.

Dampener of grain is a collapsible metal structure and consists of the main assembly units: a cylindrical rotor body, a drive, a grain indicator and a water supply control panel. The body is made of carbon or stainless steel with 3 mm thickness and has a horizontal connector. Both halves are bolted together. The housing has walls from the ends where the supports for the installation of the bearing housings are bolted. The body has an inlet (top) and outlet (bottom) branch pipes.

Specifications:

| Indicators |

А1-БШУ-1 |

А1-БШУ-2 |

1. Technical productivity for wheat grain with an average density

(770-850 kg/m3) and humidity from 10.5 to 14.5%, not less, t/h |

12 |

6 |

| 2. Increasing grain moisture, maximum, % |

5 |

5 |

| 3. Diameter of the cylindrical part of the machine body, mm |

300 |

300 |

| 4. Length of the cylindrical part of the machine body, mm |

1150 |

2150 |

| 5. Quantity of beaters, pieces |

8 |

16 |

| 6. Machine rotor speed, rpm |

1 160 |

1 160 |

| 7. Electricity consumption, kW/h |

2,4 |

3,1 |

| 8. Water consumption, within, l/h |

150 |

360 |

9. Water pressure at the inlet to the pressure reducing valve, MPa |

0,2 |

0,2 |

| 10. Weight, kg |

309 |

383 |

Dampener design:

The rotor is the main working body of the machine. It consists of a shaft made of a hollow steel tube with beaters welded onto it. The beaters have races installed with a plane to the rotor axis at an angle of 60° or 7 ° - 8 pcs. The beaters and races are made of alloy or stainless steel. The rotor is driven by an electric motor through a V-belt transmission.

The drive and grain feeding is controlled by the remote automated mode from the central control panel. The machine is idle from the central control panel. Than product is fed through the inlet of the grain indicator. Under the action of the grain flow, the plate with the lever is deflected and a sensor is triggered, which sends a signal to the membrane valve located on the water supply control panel. The water supply control panel is a vertically positioned metal platform on which filtering, regulating, executive and control devices are located. A diaphragm valve with an electromagnetic drive opens the opening for the passage of water. Water from the water supply through the valve, filter, membrane valve, and the rotameter enters the inlet of the machine, mixing with the grain.

Thanks to the special design of the rotor and its high speed, the grain is intensively mixed, saturated with moisture and moved from intake to discharge. Further, the grain is fed by gravity for further processing.