Purpose:

Sewing machine МЗМ-40 is designed for sewing fabric bags according to State Standard (ГОСТ 8516-76 and ГОСТ 2226-75) filled of bulk product. These machines are designed to work at enterprises of the Ministry of Agriculture and Food, as well as at other enterprises where the technological process includes the operation of sewing bags. The machines are completed with sewing heads for sewing fabric or polypropylene bags 38А or 38Д.

With a technical performance, the weight of the product in sewn-in bags is 50-55 kg. It is allowed to sew bags with a product weighing 100 kg, while the capacity value is not more than 60% of the technical capacity.

Specifications:

| Name |

МЗМ-40 |

| 1. Technical capacity (the weight of sewn-in bags is 50 kg), pcs/h |

600 |

| 2. Maximum weight of sew-in bag, kg |

100 |

| 3. Speed of transporter belt motion (sewing speed), m/s |

0,15 ± 0,02 |

| 4. Transporter length between drum axis, mm |

3 000; 4 000; 5 000 |

| 5. Weight, kg, max |

450; 560; 630 |

| 6. Dimensions, mm |

|

| - length |

3 285; 4 285; 5 285 |

| - width |

1 200 |

| - height |

1 530 |

| 7. Power of transporter drive, kWt |

1,1 |

| 8. Power of sewing head drive, kWt |

0,25 |

| 9. Installed failure-free operation, hours, minimum |

160 |

| 10. Average time to fail, h, min. |

1 500 |

| 11. Installed service life, year, min. |

|

| - to average repair |

3 |

| - full |

10 |

| 12. Specific total operative laboriousness of technical service, max. |

0,011 |

| 13. Specific total operative laboriousness of average repair, max |

0,018 |

| 14. Readiness rate, min |

0,99 |

| 15. Technical using rate, min |

0,95 |

Product structure:

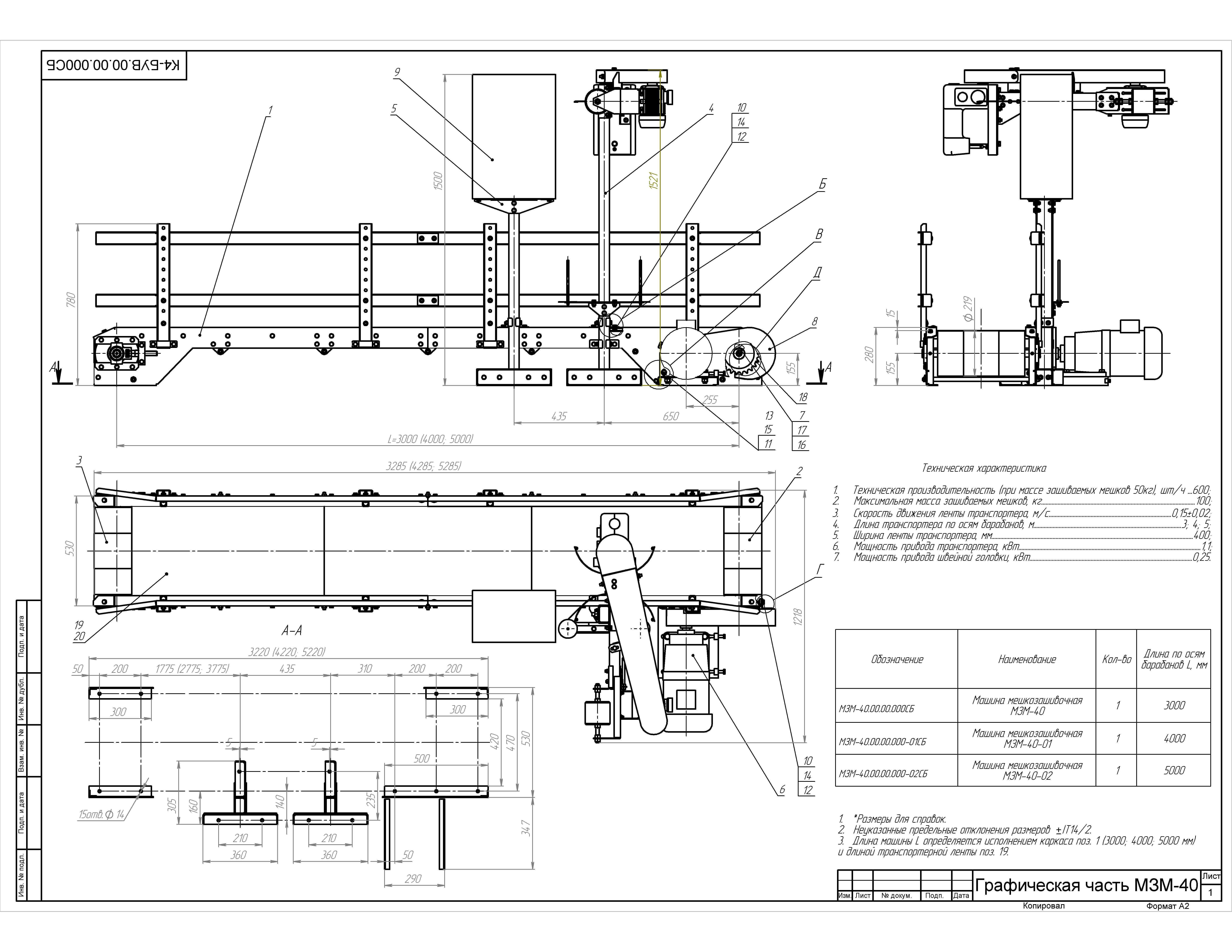

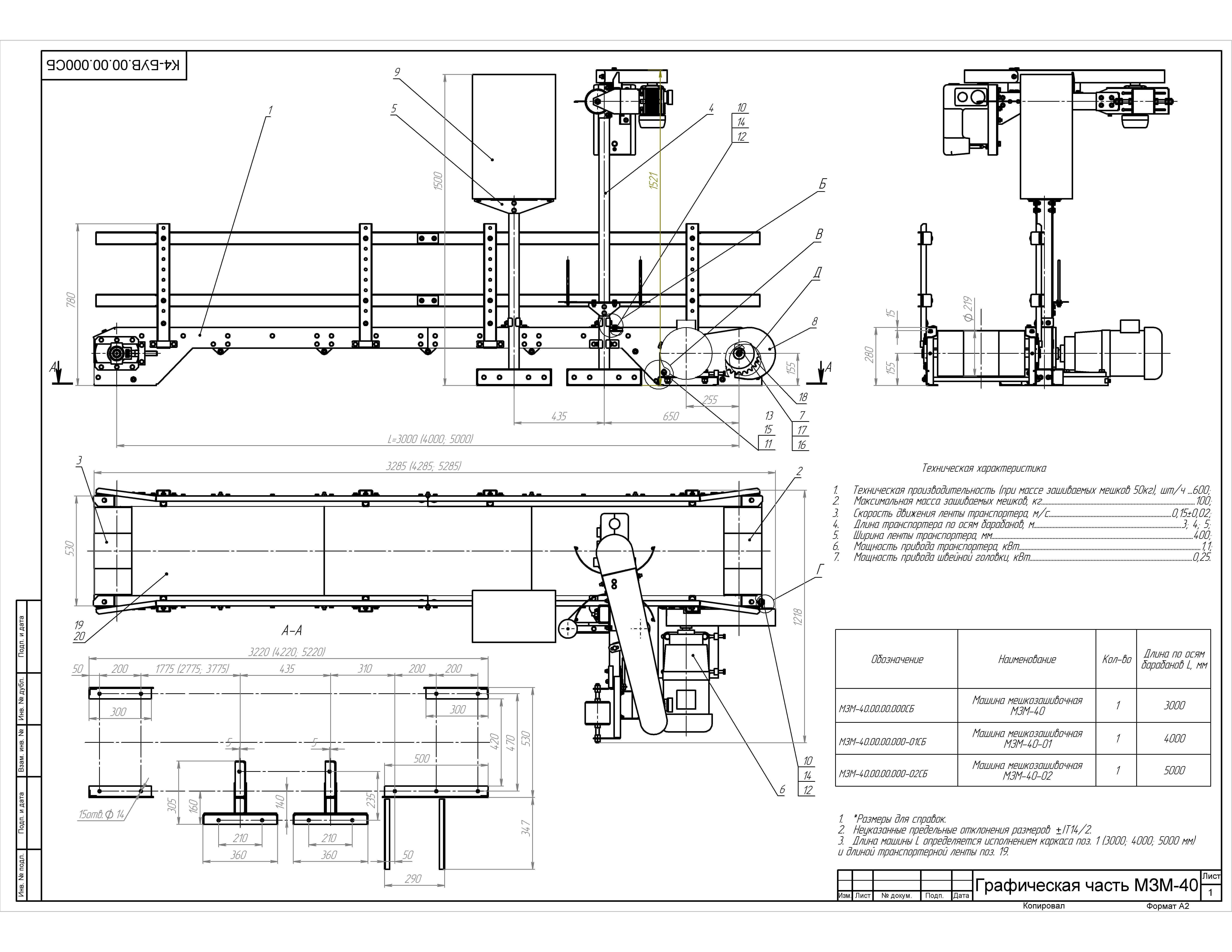

Sewing machine МЗМ-40 (Annex №2) consists of the following parts:

- frame;

- drive drum 219 mm;

- non-driven drum 219 mm;

- sewing head;

- support of control cabinet;

- drive;

- drum sprocket;

- control cabinet.

Set complete:

The machine is supplied disassembled partly as per the list of elements (Annex №3). Maintenance documentation (Annex №1).

Design and principle of operation of the machine and elements:

- Unit for sewing head. Unit for sewing head is designed for fixing of sewing head and for adjusting of sewing process. It consists of support, bracket, drives, sewing head, fence, thread routers, thread holders, the weight on the bracket.

- Transporter . Transporter is designed for moving bags filled on by product, into the sewing head for sewing. It consists of the frame with bag fence installed on the supports due to clampings; drive and non-driven drums (219 mm) installed and moving in the framework of frame; transporter belt. Routers of the bag fence are adjusted in depend on bag height.

- Drive. Drive is designed for torque supply due to chain transmission from gear motor drive drum of transporter. It consists of: gear motor with sprocket; the frame of gear motor installed at the frame of the transporter; chain fence.

- Control cabinet. Control cabinet is designed for placement of electric equipment and control tool. It installed on the support with hole. The hole is designed for mounting to the foundation and frame of the transporter. There are management bodies with explanatory nameplates on the façade of the control cabinet. There is a torch on the frame of the control cabinet. The torch is designed for lighting sewing process. The drives are connected to the control cabinet by cables.

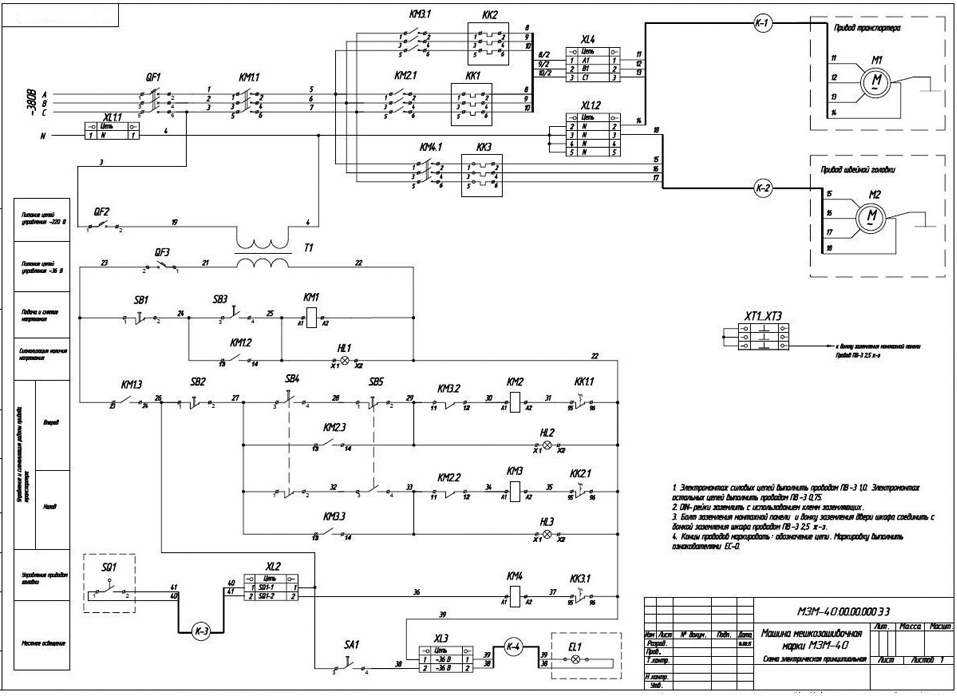

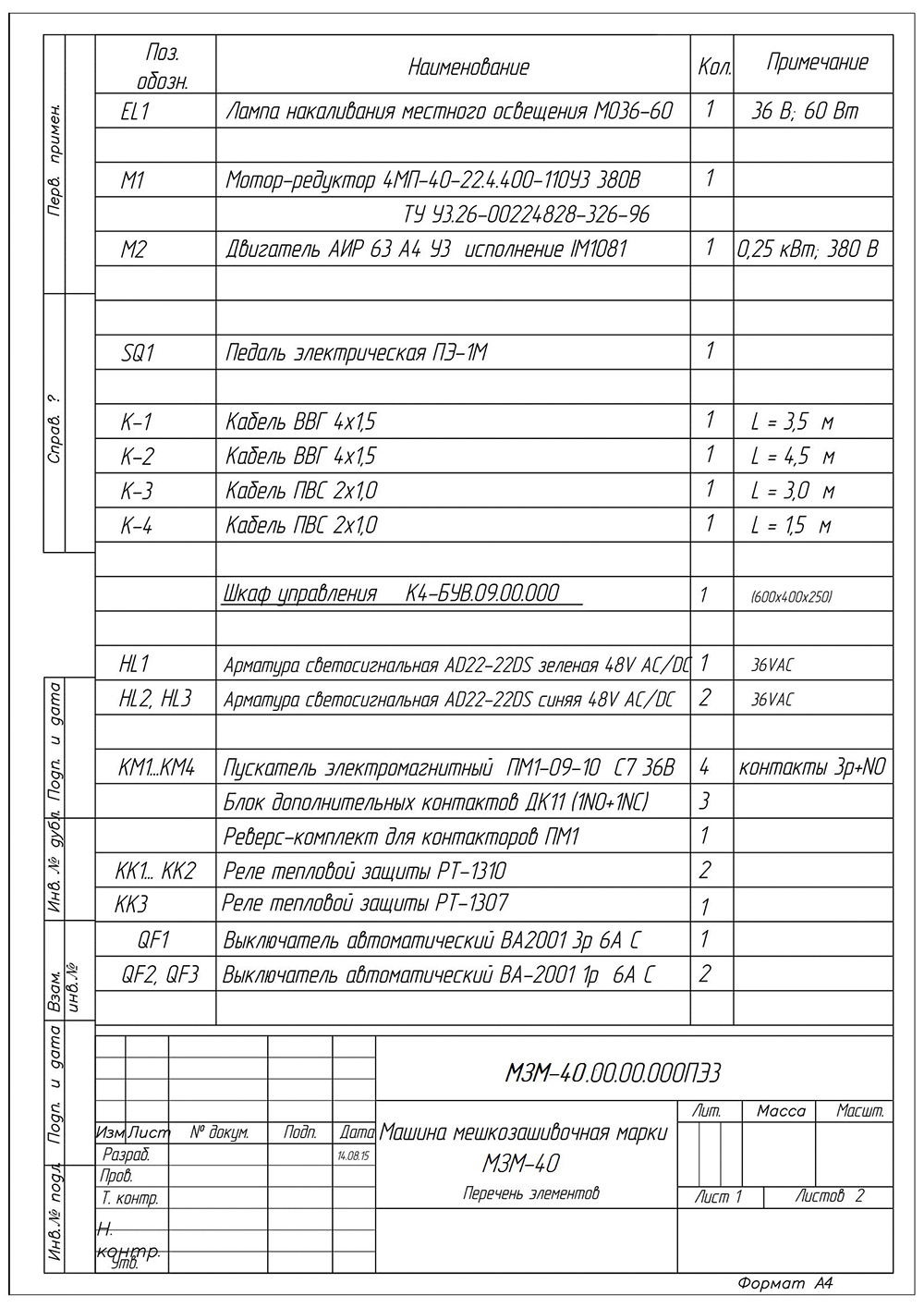

There is the following electric equipment on the machine:

- Electric drive of the transporter (М1);

- Electric drive of the sewing head (М2).

Foot switch (SQ1) for control of sewing head drive is on the floor next to the operator working place.

There is the following tools on the facade of control cabinet:

- Button “Unplug the unit” (SB1) – it means complete removal of supply voltage;

- Button “STOP” (SB2) – it means stopping the conveyor when moving in any direction;

- Button “Activate” (SB3) – it means zero protection function in the electric supply scheme;

- Button “Ahead” (SB4) – let go transporter ahead;

- Button “Back” (SB5) – let come transporter back;

- Warning light (HL1) – control of power presence;

- Warning light (HL2) – control of the movement of transporter forward;

- Warning light (HL3) – control of the movement of transporter back;

- Switcher (SA1) – switching on and off local lighting.

There are the following device inside cabinet:

- Automatic switches (QF1, QF2, QF3) – carry out protect of circuit protection against short-circuit currents;

- Transformer (Т1) – feed the voltage control circuit ~36 В;

- Starters (КМ1, КМ2, КМ3, КМ4) – provide the power and control drives of the transporter and sewing head.

- Thermal relay (КК1, КК2, КК3) – carry out thermal protect of drives.

- Description of work scheme. For voltage supply into the cabinet, it's necessary to turn automatic switch on (QF1, QF2, QF3) and push the button “Activate” (SB3). Pushing the button “Ahead” (SB4) you activate reversible starter and transporter drive (M1). The bag moves through transporter under the paw of sewing head. Herewith the operator should push the foot switch (SQ1) to turn sewing head (M2) drive on. Starter began to work, and the sewing began too.