Purpose:

Screening machine HPX-8 are continual process machine designed to clean oilseeds at oil extraction plants.

The machine made according to 3rd category of State Standard (GOST 15150, climatic execution “У”) for domestic market and export to temperate countries. Concentrator should operate in working terms at the temperature from - 10 °С to + 40 °С. Relative humidity should be 80 % if average annual temperature is + 15 °С and atmosphere pressure is 650-800 mmHg (86,6 – 106,7 kPa).

Operation modes can be one-shift, two-shift or three-shift.

Specifications:

| Name: |

НРХ-8 |

| 1. Technical productivity (depends on work intensity), max., t/day |

150 |

| 2. Rotation frequency, RPM |

|

| - with frequency control drive |

560 - 630 |

| - without frequency control drive: |

|

| - with motor pulley Ø 125 |

560 |

| - Ø 133,9 |

600 |

| - Ø 140,6 |

630 |

| 3. Rotor diameter, mm |

800 |

| 4. Rotor width, mm |

2 150 |

| 5. Installed capacity, kWt |

2 х 9,2 + 0,75 = 19,15 |

| 6. Airflow consumption for aspiration, m3/h |

1 400 |

| 6. Fixed operation life without overhaul, year, min. |

5 |

| 7. Total fixed operation life |

8 |

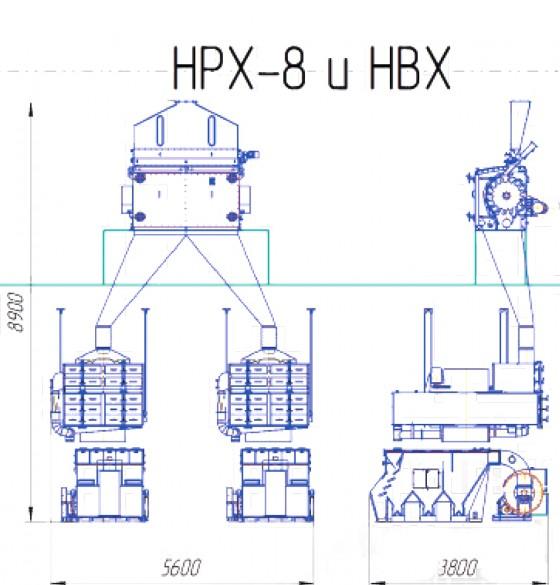

| 9. Dimensions, mm: |

|

| - length |

1 735 |

| - width |

2 900 |

| - height |

1 715 (1 915 asp) |

| - with hopper over the feeder |

2 725 |

| 10. Weight, kg (max.) |

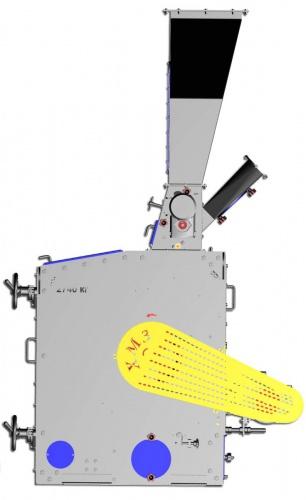

2 740 (2 880) |

Work quality parameters:

| Parameters |

Original mixture |

Large seeds |

| 1. Content, %: |

|

|

| - whole seeds |

10,98 |

12,68 |

| - unprocessed seeds |

8,84 |

4,82 |

| - kernel |

40,48 |

43,87 |

| - husk |

12,50 |

18,41 |

| - broken seeds |

11,07 |

8,49 |

| 2. Oil dust, % |

16,13 |

11,73 |

Design and principle of operation:

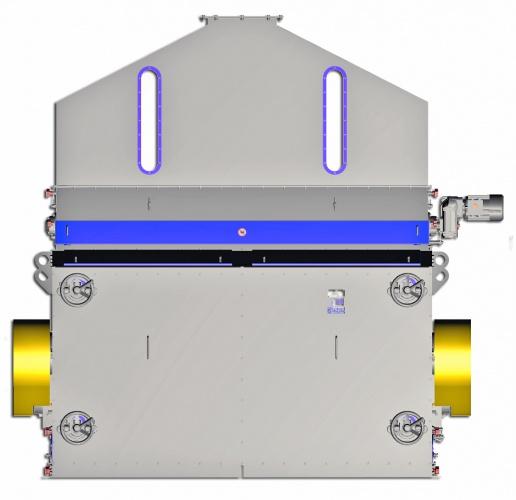

The machine (drawing 1) consists of body (1) with installed bearing units, which hold rotor (2), deck (3), deckholder (4), low and upper mechanisms of control of gap between rotor and deck (5 and 6), feeder (7), controlled reflector (8), drive (9), fences (10 and 11), aspirating nozzle (12). This machine doesn't have own fan and joins central aspiration pipe). Rotor rotates due to the belt drive of back wall drive (21).

There is feed roller (14) in the feeder (7). The roller rotates due to the motor gear (15). The product is spread on feeder due to adjusting valve (16) and feed roller (14). Then the product goes to the feed tray (17). The feed tray is designed to get seeds in the working area between the rotor and deck (in screening chamber). On request, the feeder can be equipped with magnetic protection. The seeds processed by impact kits and then seeds go to the grooved surface of the deck. After screening, Kernels and husk through the reflector move into the machine exit.

Seeds screening intensity is adjusted by changing gap between the deck and impact kits. Figure “0” on bolt scale means the gap is minimum (6-8 mm) between the deck and rotor. While adjusting minimum gaps, to avoid cutting of upper limiter, the index value of lower gap shouldn't be more 20 mm than upper gap. The difference of side indexes shouldn't be more than 1 mm.

Attention! To avoid the damages, the customer should carry out adjusting of the gap between the deck and rotor or reflector angle ONLY while the engines off. After the adjusting, you should rotate the rotor manual (without fence). The rotor should rotates easy. Afterwards, yu can engine on and machine start.

To achieve design performance, the following steps must be taken:

- To install normal circumferential speed (25 m/s = 600 rpm) for impact drum. To achieve seed distribution along the entire length of the drum by adjusting the gate in the feeder.

- To place the impact kits away from the grooved surface of the deck in accordance with kind of seeds and humidity. The adjusted position of the grooved surface of the deck in relation to the scourge drum and the selected circumferential speed of the drum must ensure the performance specified in the passport.

- To adjust seed flow due to gap change between valve and grooved roller.

- To adjust normal airflow mode in the screening chamber.

Airflow speed should be adjusted so, that no seeds are allowed in the small flow during intensive aspiration.

During machine work, you should control:

- To save the installed load, preventing its change, since a decrease or increase in the load reduces the efficiency of the machine;

- To work feeder roller and valve and to keep uniform distribution of seeds along the entire length of the roller;

- Reflector status;

- To keep normal air mode and normal seeds blowing, to cancel gaps in the machine and aspiration system to avoid suction outside;

- For good bearings condition (lubrication and temperature);

- For normal work of drive belts;

- For presence of fences of pulleys and belts;

- For clearance machine.