Purpose of equipment:

Steamer ПЗ-3 is designed to cook cereals and grains, as well as other bulk products under the saturated steam overpressure and continuous product stirring with a stirrer.

Specifications:

| Parameter |

ПЗ-3 |

| 1. Volume, m3 |

|

| - full |

1,0 |

| - load |

0,75 |

| 2. Capacity (depending on crop and steaming mode), kg |

1 000 - 1 500 |

| 3. Working pressure, MPa |

0,05 ÷ 0,4 |

| 4. Maximum ambient temperature in the housing, оС |

148 |

| 5. Rotation speed of mixer, (RPM) |

18 - 21 |

| 6. Dimensions, mm: |

|

| - length |

1 600 |

| - width |

1 760 |

| - height |

4 085 |

| 7. Weight, kg |

1 400 |

Steamer device:

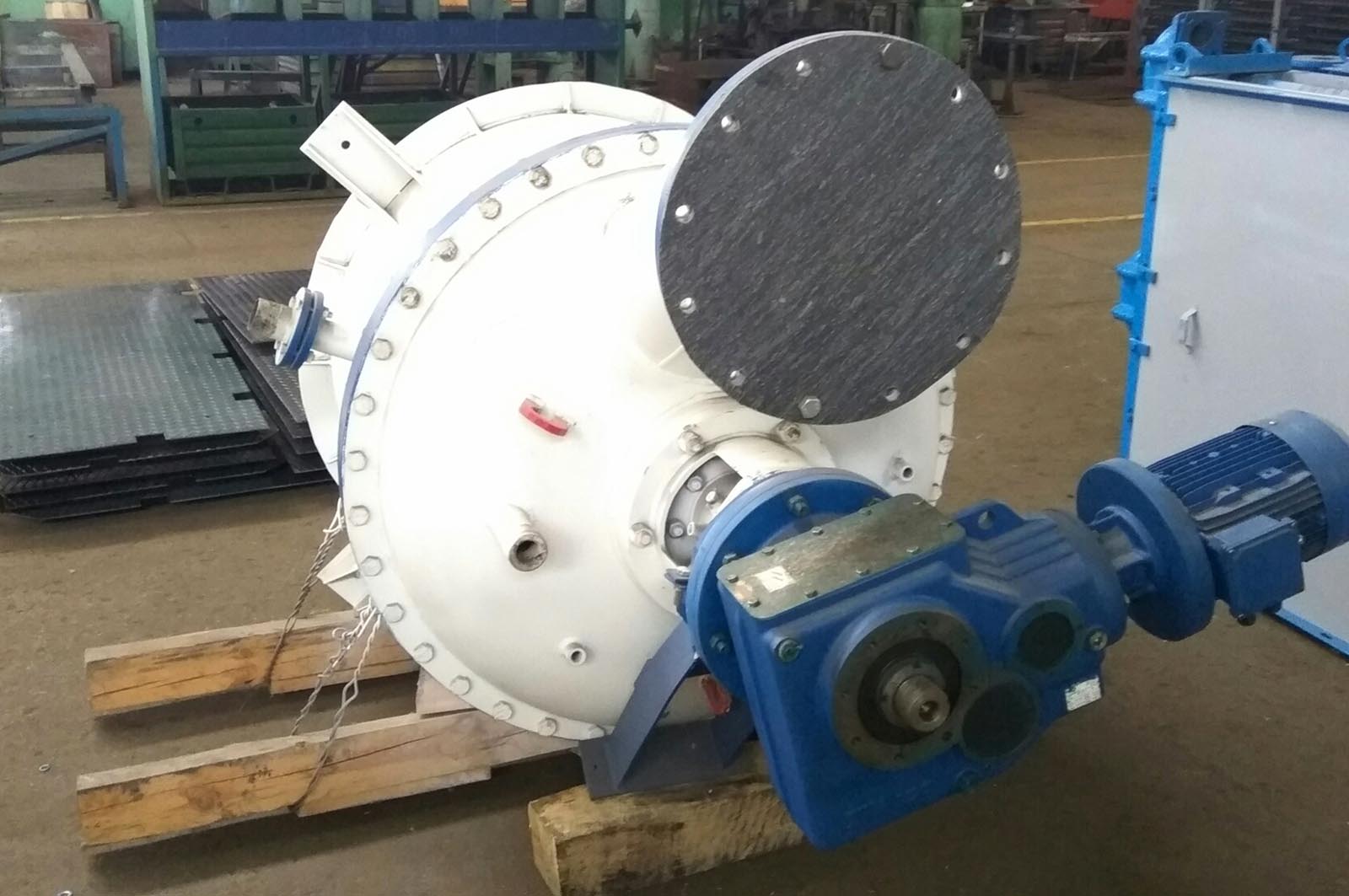

The machine has cylindrical case, spherical bottom and cover. There is gearbox (made by FLENDER) in the center of the spherical cover. This gearbox is needed for mixer drive. There is the inlet nozzle (Ø 300 mm) in the spherical cover, but it located away from the driver. The loading unit is mounted to the inlet nozzle by flange connections. The loading unit is made in the form of cylindrical pipe (Ø 300 mm, height = 1 200 mm). There are gate valves with pneumatic drive at the inlet/outlet of the cylindrical pipe. Operation of the loading unit looks like lock chamber work. There are electric manometer, explorer safety valve and level sensor (t – 250 оС) are at the spherical cover. There is the outgoing hole at the center of the spherical bottom. The sealing lock feeder with drive unit is mounted to the outgoing hole.

The steam shirt mounted to the spherical bottom all over its surface. This steam shirt has steam pipes and condensate outlet nozzles. The special mixer is inside the steam machine. There are nozzle for steam supply and technical hatch for inside work in the side of the cylindrical body. The machine is made of food stainless steel.

The machine controlled by control panel based industrial controller. It let us change modes of steaming and cooking (the pressure of steam and time of cooking) for different type of products.

Principle of operation :

Before steamer work, it should be heated by blow steam through the steam shirt. After body heating, control panel is adjusting for automatic operation. The start of the work is opening upper gate valve of the loading unit. The opening is carry out by pneumatic cylinder. Then the product goes from the loading hopper to the loading nozzle. After then the upper pneumatic gate valve is closing. And, the lower pneumatic gate valve is opening, and the product goes from the loading unit inside the body of steamer.

The pneumatic gate valve is closing, and pneumatic valve is opening to get the steam excessive pressure out of loading unit (6) for 6 seconds. Afterwards, this process repeats the same way.

While loading and before the first portion of the product enters the machine, mixer drive is starting, and pneumatic valve is opening for steam supply inside the body. The mixer mixes the product while simultaneously exposed to steam and the high temperature of the wall of the spherical bottom heated by steam.

The loading carries out until the sensor of product level in steamer turns on. After then the loading is finished, and the product is processed by steam condensate agent for determined period. Afterwards the sealing gateway is starting work. It provide with discharging of needed productivity.

It a minute, the steamer loading continues. You should glean needed productivity (from 0 to 1 500 kg/h) due to adjustment of the rotor rotation speed of the sealing gateway. In depend of processed product, you should choose steam mode due to microprocessor keyboard. It may be steam pressure and time of steaming. Then you choose these parameters you can turn on automatic mode of the steamer. At the request of the operator, the steamer control mode can be changed to semi-automatic or manual.

The Steamer completed with:

| Position |

Name |

Number |

| 1 |

Steamer ПЗ-3, body with mixer inside (100% made in stainless steel) |

1 |

| 2 |

Safety valve 17с12stainless st, disraptive |

1 |

| 3 |

Stop valve with pneumatic drive 22Б604р Dу 50 for steam, pcs. (for steam come in and for exhaust of used steam) (stainless steel, bronze) |

2 |

| 4 |

Manometer ДМ 2010 Сr, pcs |

1 |

| 5 |

Switch of grain limit level СУ, pcs. (tпред.= 250oС) |

1 |

| 6 |

Pneumatic gate valve for inlet and outlet of the grain ДУ-200 with position sensors |

2 |

| 7 |

Automatic control panel for the Steamer. It is on the base of the controller and component parts of Siemens |

1 |

| 8 |

Panel of preparation and control of pressed air. It is on the base of the component parts of Camozzi |

1 |

| 9 |

Passport ПЗ-3, pcs |

1 |

| 10 |

Documentation package is including: |

|

| а) general view of the Steamer, scheme of outlet – 1 page |

1 |

| б) electric scheme - 4 pages. |

1 |

| в) pneumatic scheme |

1 |

Attention! Thermal insulation material, external piping, external connection cables are not included in the scope of delivery of the manufacturer.