Purpose:

Husk separator is designed to separate oil dust from the sunflower husk. It used at crushing section of extract oil plants. It also can be used for sifting of sunflower meal and wheat cleaning too, if this model is modernized in sieve replacement and change of frequency of drum and rotor rotation.

Specifications:

| Name |

СЛ-40 |

| 1. Productivity for husk, t/day |

40 * |

| 2. Installed capacity, kWt |

|

| - basic drive |

15,0 |

| - screw |

1,1 |

| 3. Rotation speed, RPM |

|

| - rotor |

620 |

| - drum |

20 |

| - screw |

75 |

| 4. Inner diameter of impact kit, mm |

420 |

| 5. Length of impact kit, mm |

3 200 |

| 6. Reduction of husk oil properties, % |

0,2 - 0,5 ** |

| 7. Periodicity of sieve blowing, sec |

20 ... 60 |

| 8. Pressed air requirements: |

|

| - working pressure, mPa |

0,5 … 0,6 |

| - consumption, l/min |

120 … 130 |

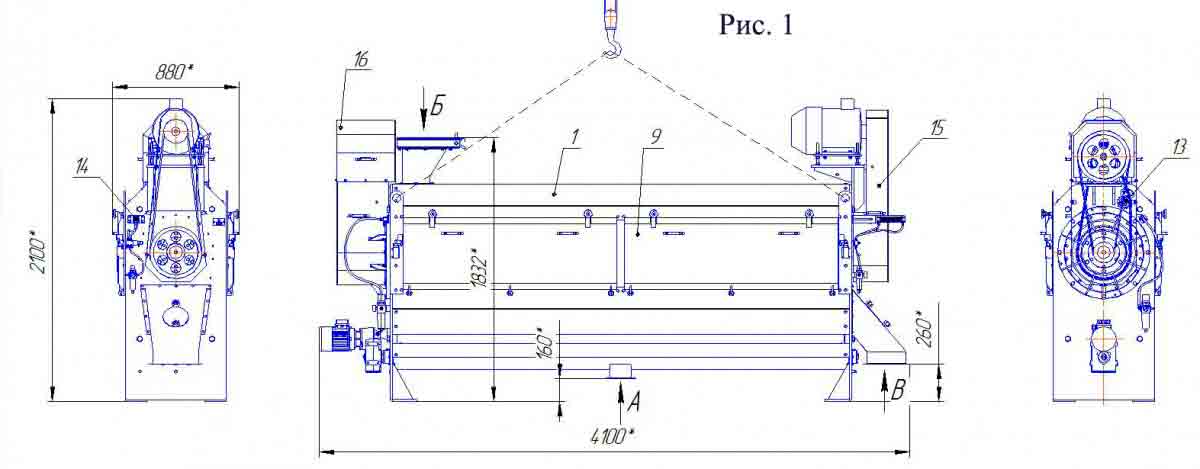

| 9. Dimensions, mm, max.: |

|

| - length |

4 100 |

| - width |

880 |

| - height |

2 100 |

| 10. Weight, kg |

1 770 |

* A short-term increase in productivity up to 45 t/day is possible with a decrease in the quality indicators of the machine.

** The oil content reduction rate depends on the initial moisture content of the product. (The optimum moisture content of the husk is 10 - 11 %, with the moisture content of sunflower 6.8 - 7.2%). With a decrease in humidity, the oil removal rate falls accordingly. It is carried out ineffective selection whole and parts of kernel (with one size is more than 2,5 mm), which increase total oil of product. It is carried out due to special machine construction which designed for selection of oil dust. The customer have to delete whole and parts of kernel before Husk separator СЛ-40.

Design and operation:

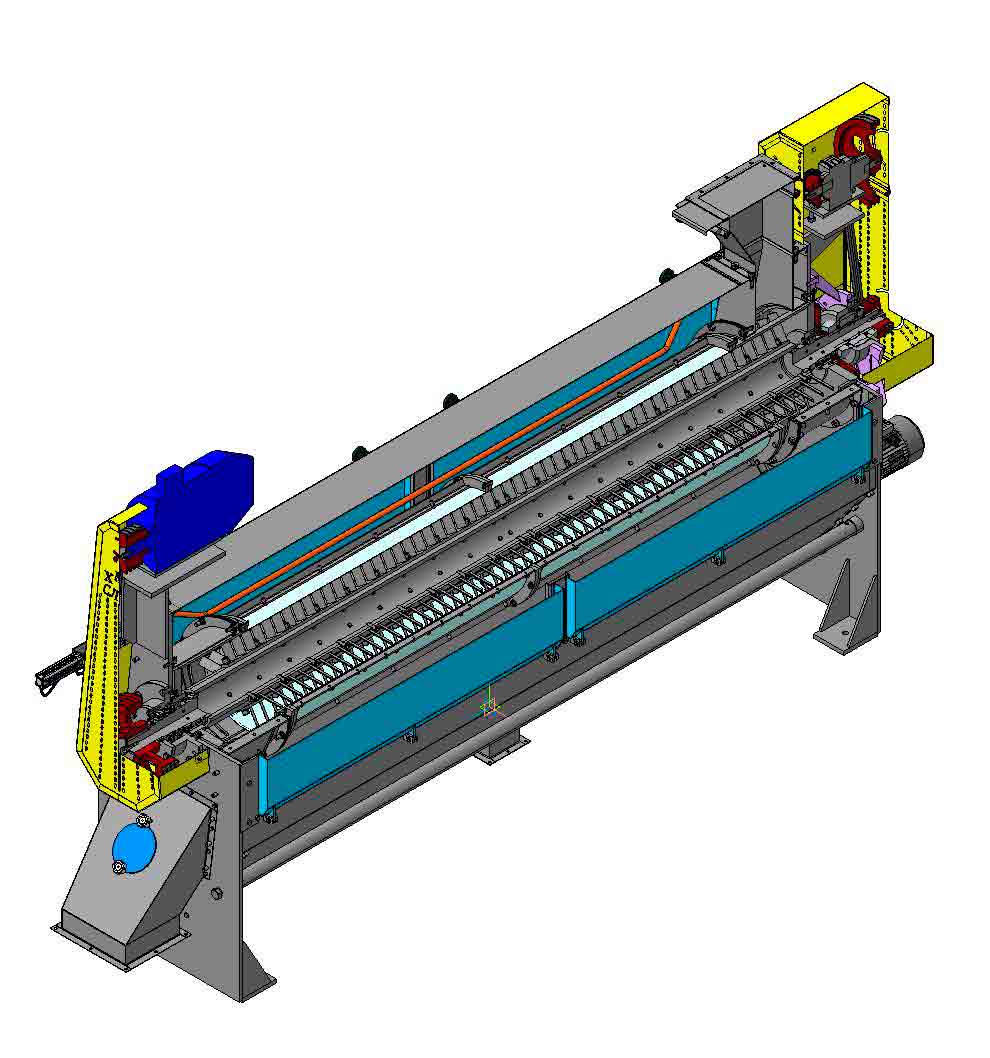

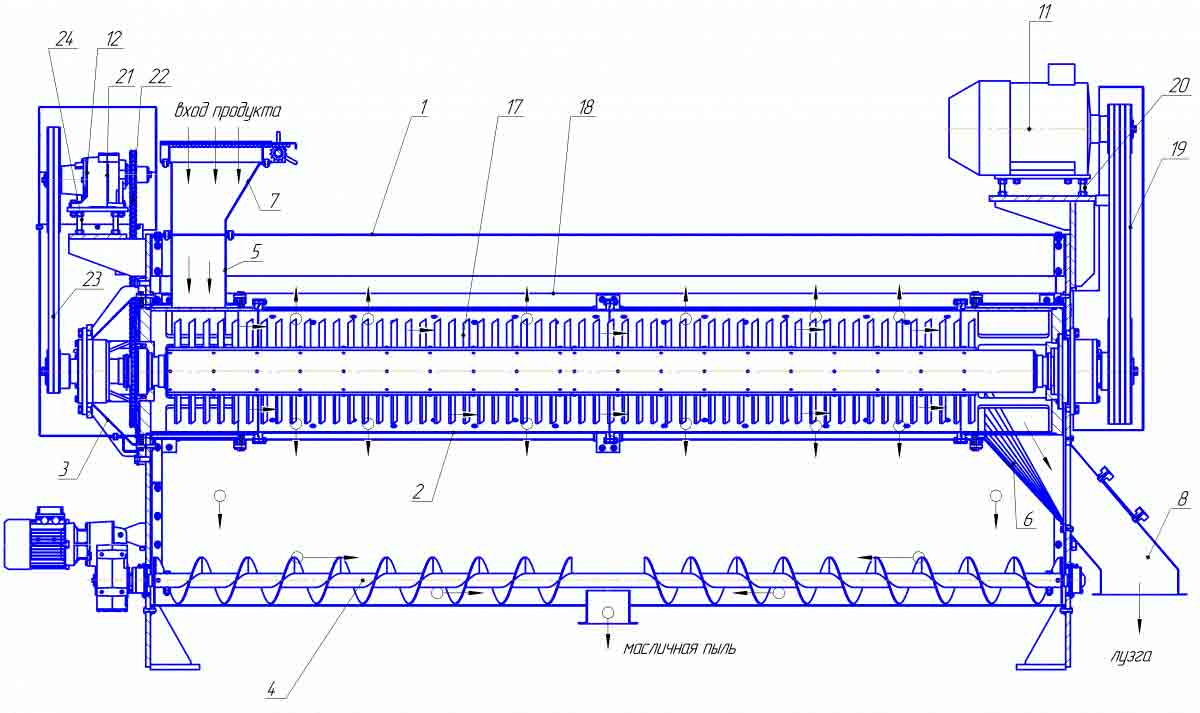

The machine consists of the following main parts: body (1), impact kit (2), bin (3), auger (4), loading device (5), unloading device (6), nozzles of loading (7) and nozzles of unloading (8), door (9), valve (10), drives (11 and 12), chain tensioner (13), cleaning system (14), fences (15 and 16) (drawings 1 and 2).

There is the main part of the machine in the body. It called impact kit. It consists of impact rotor (17), which installed in the bearing units. These units mounted to the end walls of the machine body (1) and drum (18). The drum is placed in the bearing units (on rotor roller). Thus, different rotor and drum speeds are provided. Rotor rotation is carried out by the main drive through belt drive. Standard paw engines with power 15,0 kWt are used to drive.

Belt tension (19) is carried out due to tension screws (20). Drum rotation is carried out by belt drive, reducer (21) and chain gear (22). Belt tension (23) is carried out due to tension screws (24). Chain tension is carried out due to tensioner (13). There is also auger in the bearing units installed on the end walls. Auger rotation is carried out through gear motor. The product go through inlet nozzle (7) and loading device (5) to working area, where rotary and axial motions are carried out. Product is broken by impact in the gap between the sieve and the rotor. And subsequent separation of the oil mass also is carried out there. Afterwards the oil mass is discharging by the auger. The husk goes out of machine through unloading device and outlet nozzle.

Attention! If for any reason replacement of one scourge is required, then the opposite scourge also must be replaced. If possible, it's recommended to replace the complete set. After replacement of scourges, the rotor should be balanced.

The Drum (18) (drawing 2а) consists of inlet (25) and outlet (26) and sieve drums joint in vertical surface.

For correct disassembly sieve cylinder, the customer should start work to disassemble frames (27) from side of product loading. For correct disassembly bearing units on bodies, there are threaded holes for release bolts. It pointed in drawing 2a. Clearing system (drawing 3) is designed for removal of product from the mesh of sieves.

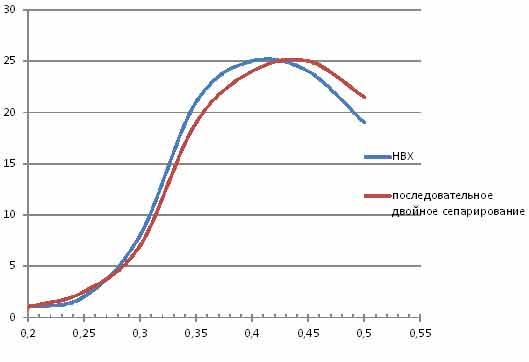

Work efficiency of the machine СЛ-40:

Reduction of husk oil content in the specification:

| Reduction of husk oil content, % |

0,1 |

0,5 |

| 1. Additionally obtained oil from 1 ton of husk, kg |

1 |

5 |

| 2. Productivity of husk processing, kg/day |

40 000 |

40 000 |

| 3. Additionally obtained oil, kg/day |

40 |

200 |

| 4. Operation mode, days in a year |

320 |

320 |

| 5. Additionally obtained oil, kg/year |

12 800 |

64 000 |