Purpose:

Grain-cleaning separator А1-БМС-6 designed to clean of grain (wheat, rye, oats etc.) from the impurities different in dimensions and aerodynamic properties. Separators are designed to use the grain cleaning machines at agricultural enterprises, including explosive enterprises.

Separators are manufactured according to the 3rd standard category (15150) in a climatic modification "U" for a domestic market and export to countries with a temperate climate. Separators have to work hard in operating modes at temperatures from minus 10 to plus 40°C relative humidity 80% at an average annual temperature of + 15° C, atmospheric pressure from 650 to 800 mm Hg (86.6 ÷ 106.7 kPa). When using special greases, the separator starts and works reliably at temperatures from minus 30° С.

Specifications:

| Parameter |

БСХ-3-1 |

А1-БМС-6 |

| 1. Technical productivity*, t/h: |

| - Preliminary cleaning (elevator mode) |

12 |

25 |

| - Finish cleaning (mill mode) for wheat with humidity of 15% (max) and impurity content up to 3% |

3 |

6 |

| 2. Efficiency of cleaning of impurities, %, min: |

| - Preliminary cleaning |

20 |

20 |

| - Finish cleaning для пшеницы with humidity of 15% (max) and impurity content up to 3% |

80 |

75 |

| 3. Installed capacity, kW, max |

2,95 |

3,75 |

| 4. Air consumption, m3/h, max: |

2 600 |

3 200 |

| 5. Circular frequency of a sieve body, RPM |

325 |

| 6. Radius of Circular frequency of body mm, max |

9 ± 2 |

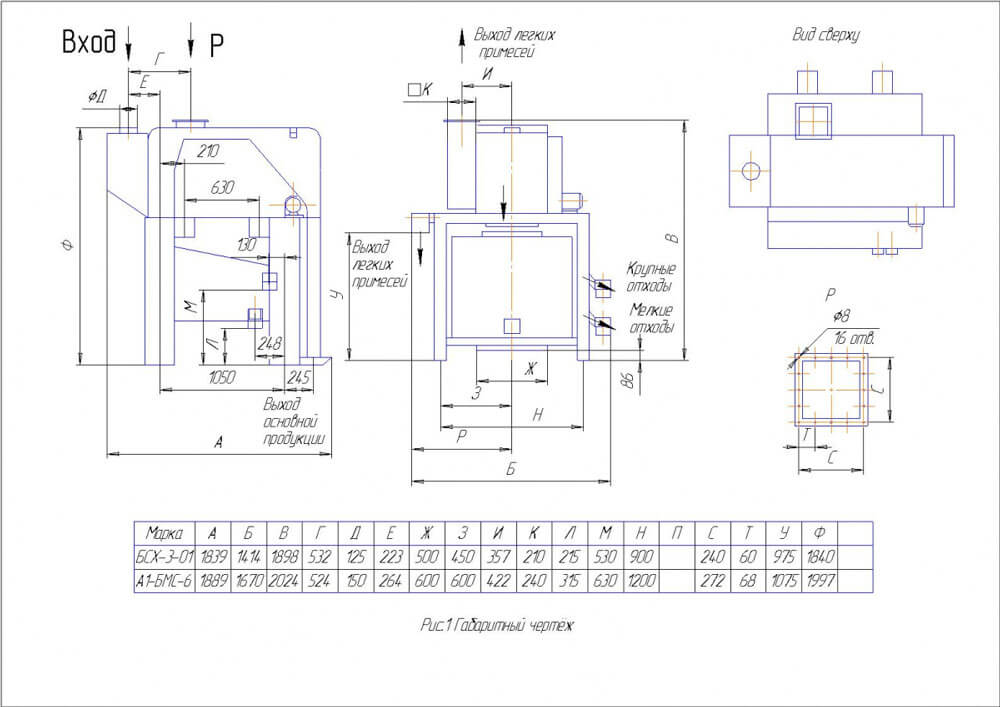

| 7. Separator dimensions, mm, max, (without cyclone): |

| - length |

1 839 |

1 889 |

| - width |

1 284 |

1 540 |

| - height |

1 898 |

2 024 |

| 8. Weight, kg, max |

810 |

965 |

| 9. Service life, years |

8 |

Note.* Technical productivity (indicated in line 1) relates to the cleaning of raw grain (for wheat with a bulk weight of 760 kg/m3 and the content of impurities (seeds and cultivated plants):

- For pre-cleaning of 15% humidity up to 20 %;

- For final cleaning of grain with impurity up to 3 % and humidity 15 %.

With an increase in the above norms of impurity and humidity of the raw material, the technical productivity of the separators decreases by 2% for every percent of impurity and by 5% for every percent of humidity. For cleaning crops other than wheat, productivity is reduced as follows:

- For Rye and corn – up to 90%;

- For millet and barley - up to 80%;

- For buckwheat and oats – up to 70%;

- For sunflower – up to 50% of the nominal.

Design and operation:

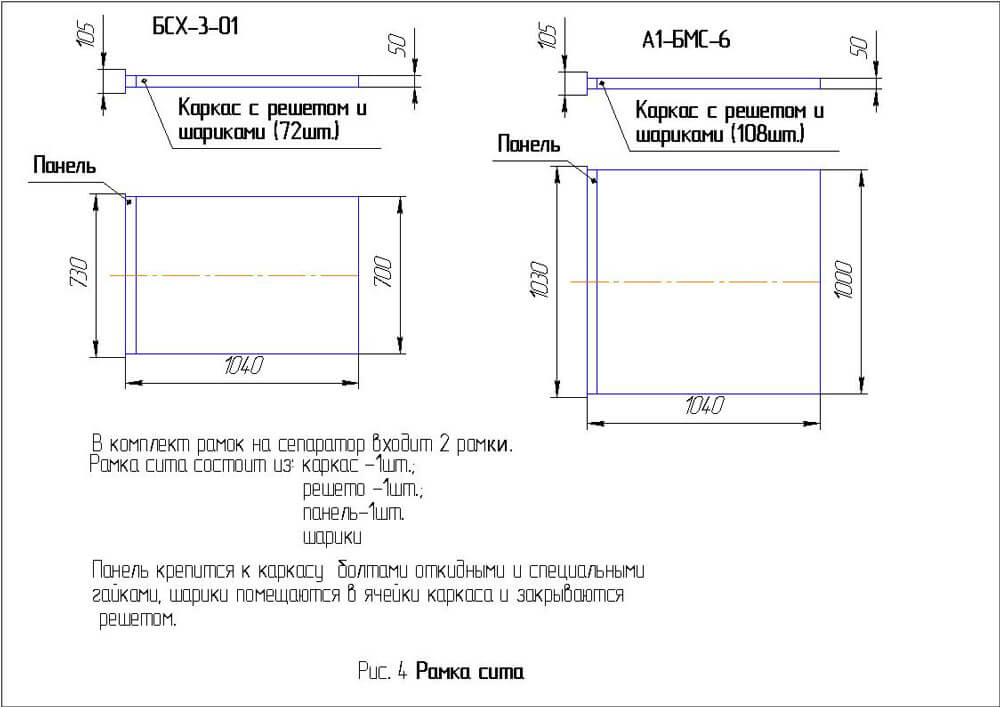

Grain-cleaning separator А1-БМС-6 consists of next points: base, body with sieve frames, traverses with balanced mechanism, fan, drive of fan, sediment chamber, pneumatic channel, screws, drive, outlet tray and fence.