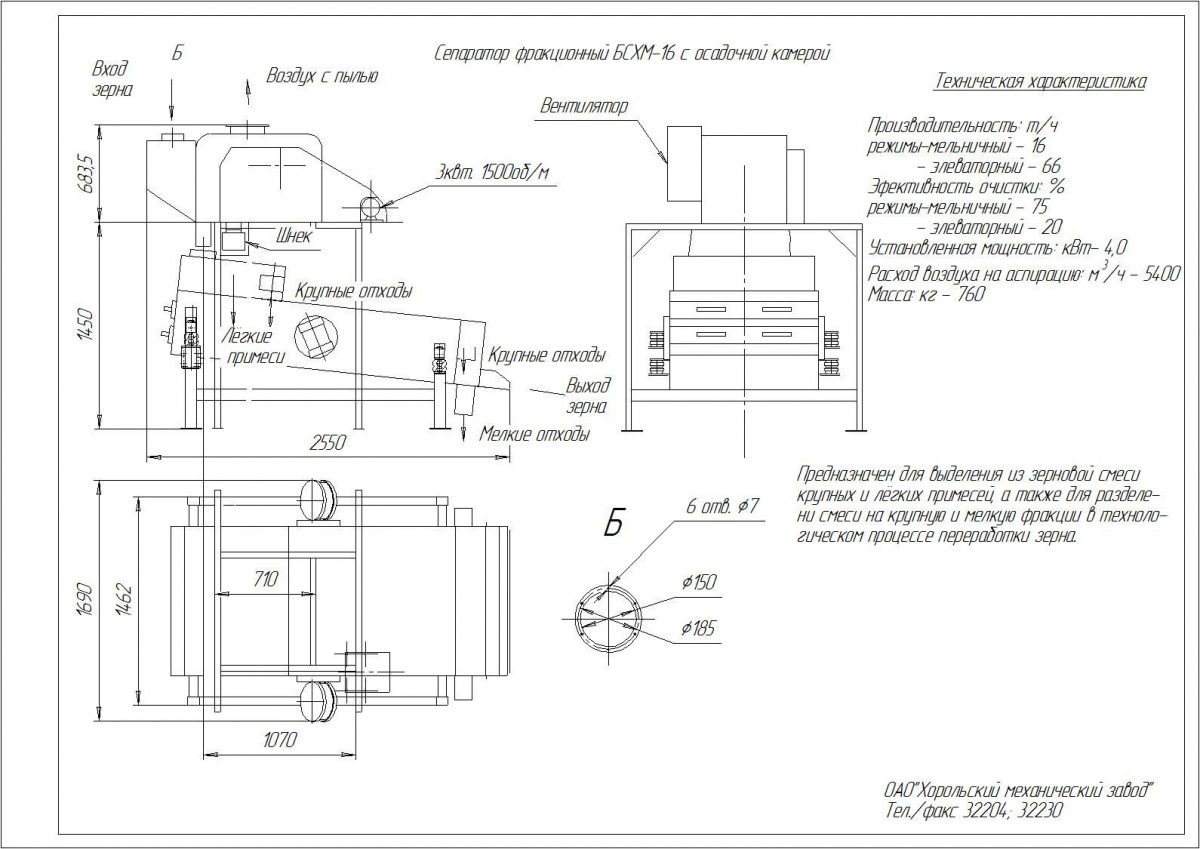

Purpose:

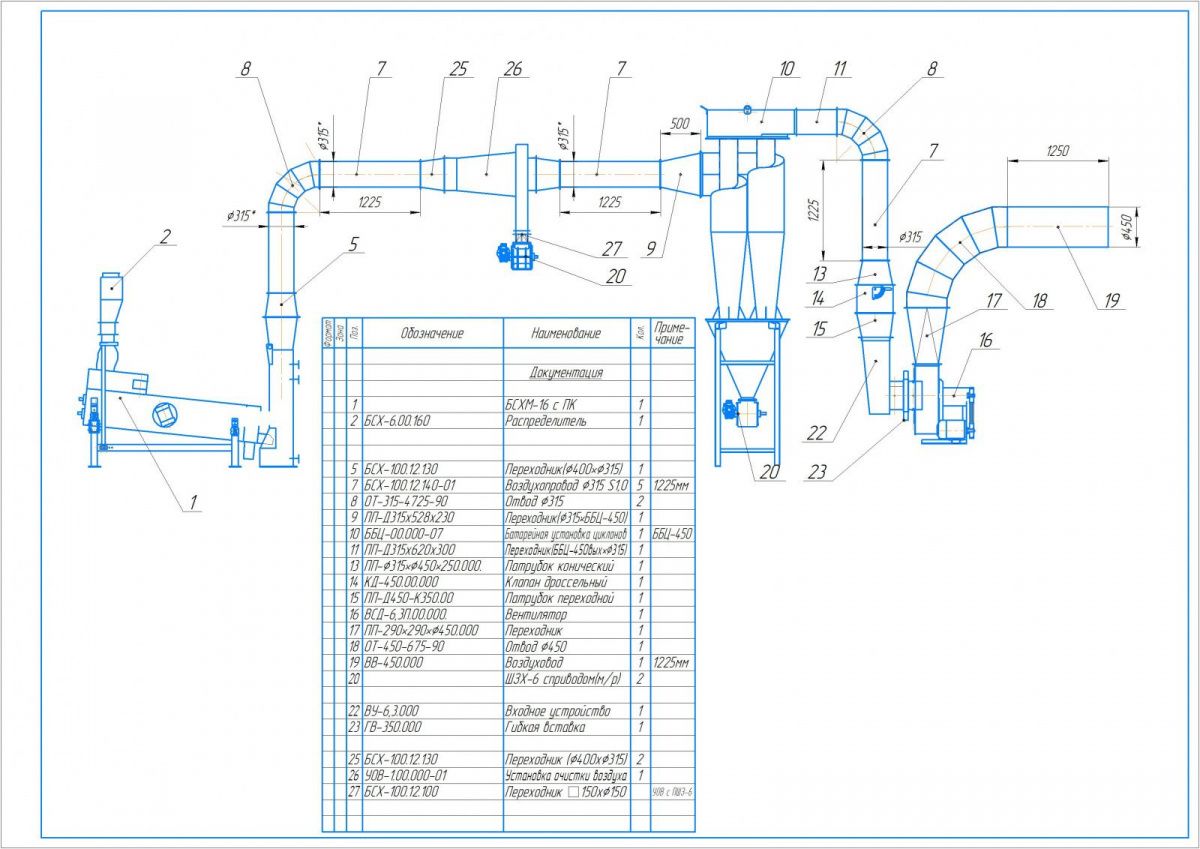

Grain-cleaning separator БСХM-16 is designed for cleaning grain from the impurities, different from it in size and aerodynamic properties; as well as for grading grain mix into separate grades.

Grain cleaning separators are installed at the mills, elevators and cereal mills.

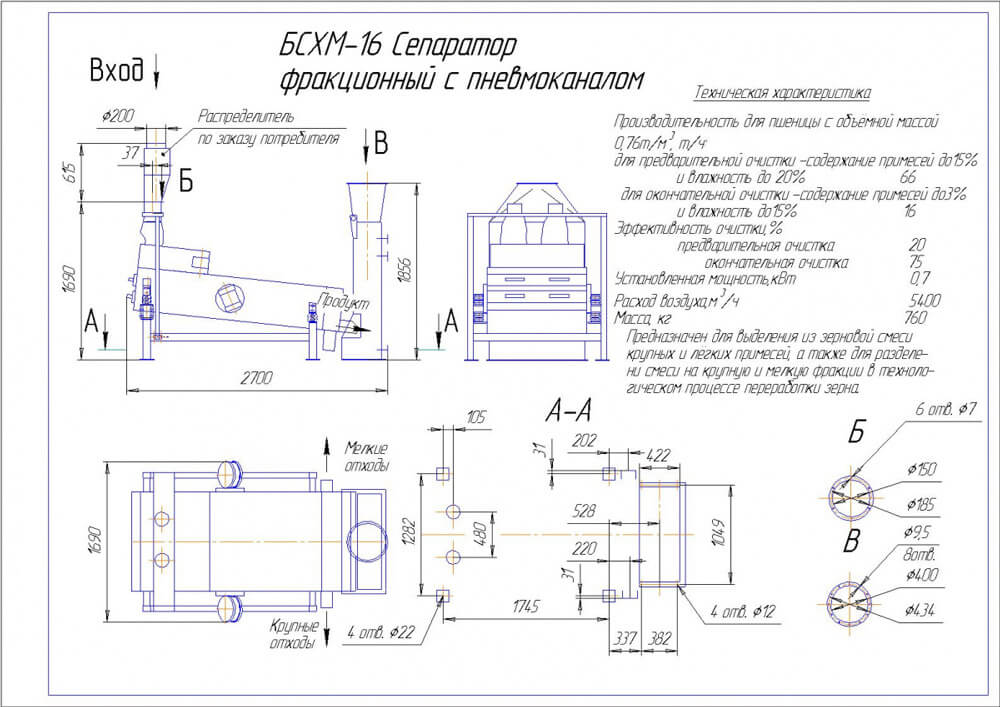

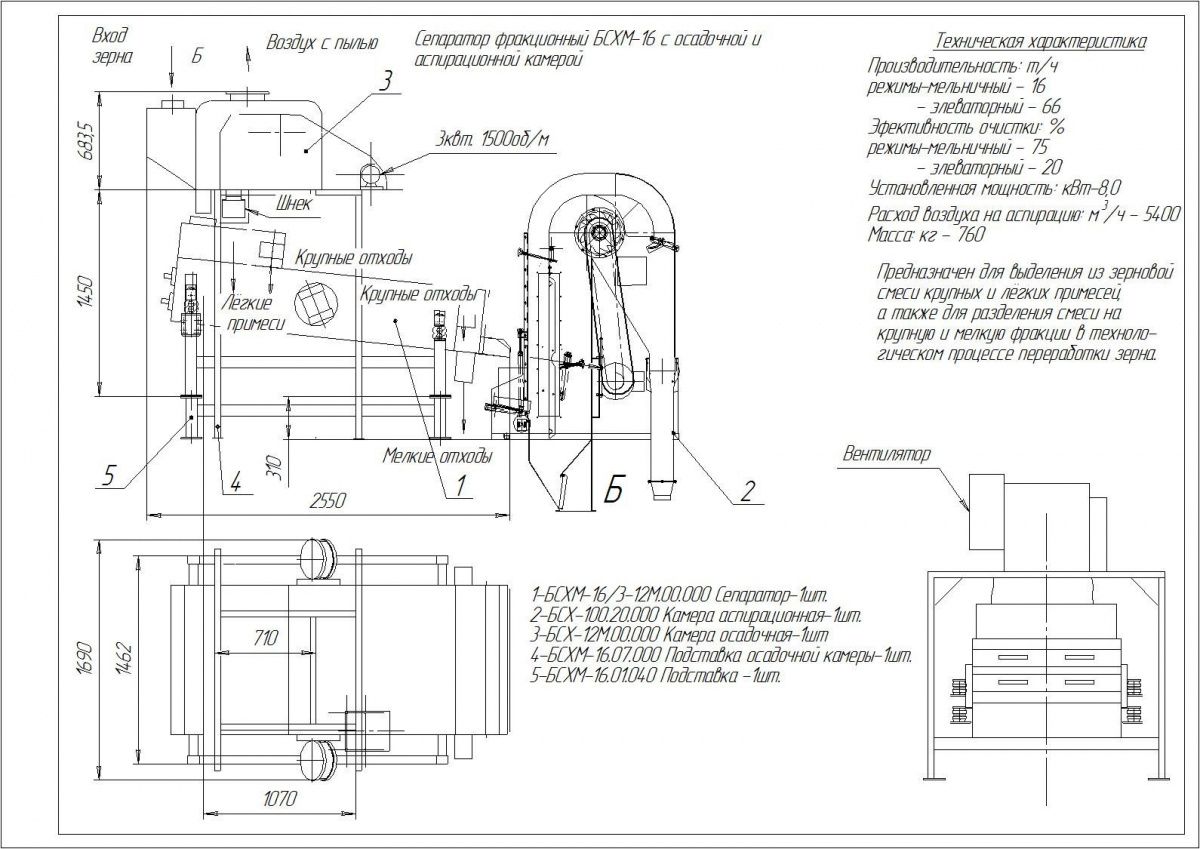

Technical specifications:

| Parameter |

БСХМ-16 |

| 1. Capacity, t/hour: |

|

| - elevator mode |

66 |

| - mill mode |

16 |

| 2. Cleanup factor, %: |

|

| - elevator mode |

20 |

| - mill mode |

75 |

| 3. Installed power, kW: |

0,74 |

| 4. Air flow, m3/h: |

5 600 |

5.Dimensions, mm: |

|

| - length |

2 700 |

| - width |

1 690 |

| - height |

1 856 |

6. Weight, kg: |

690 |

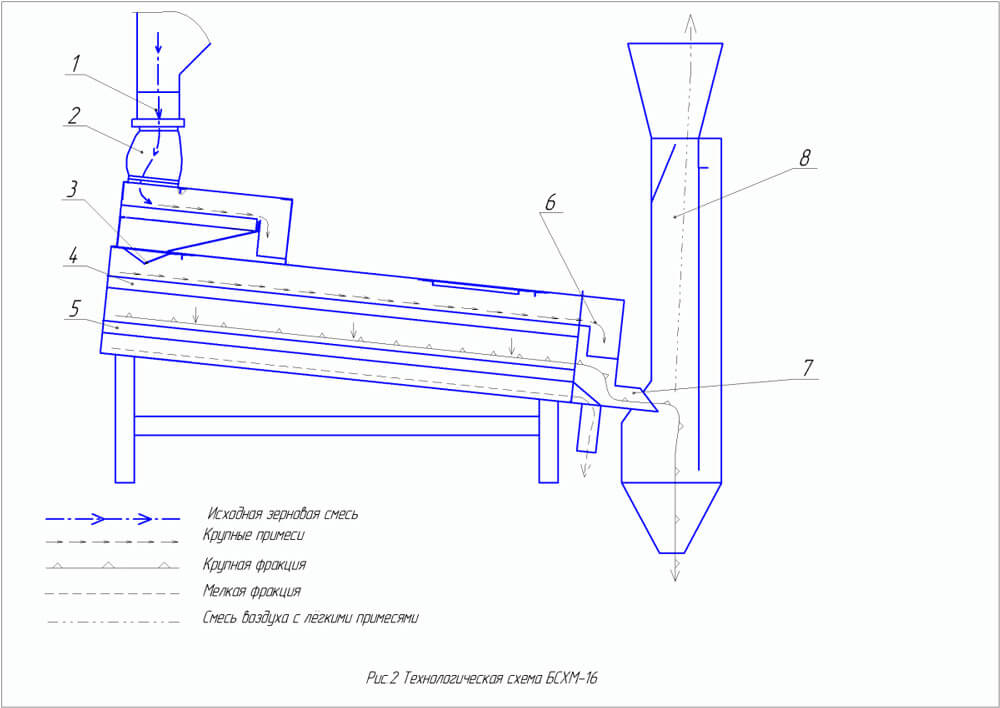

Principle of operation:

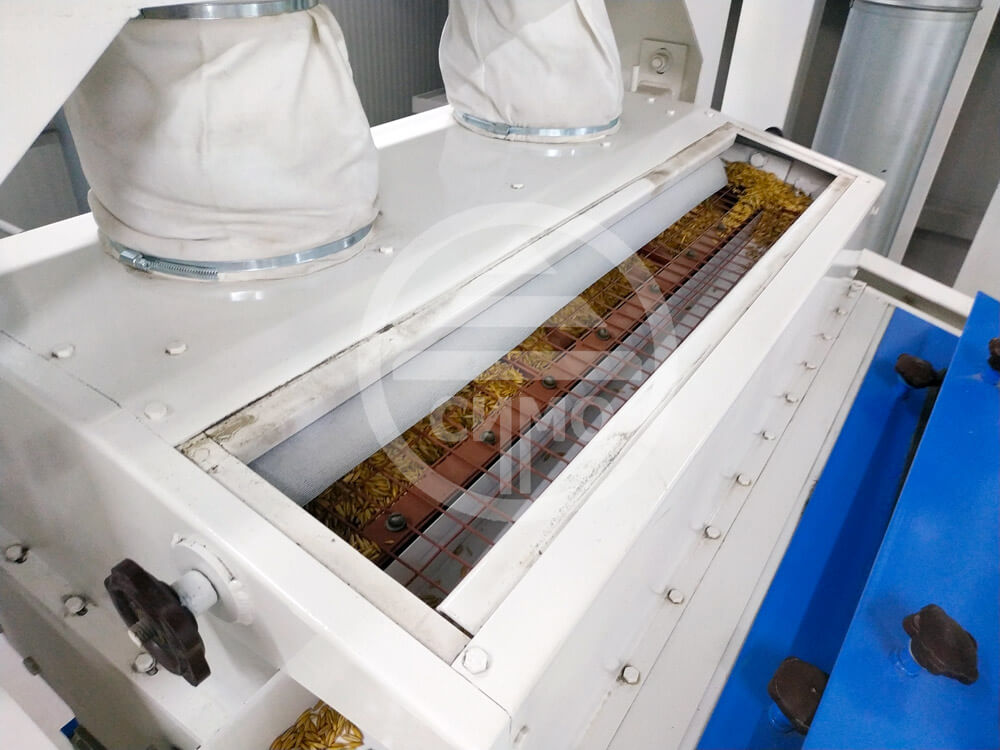

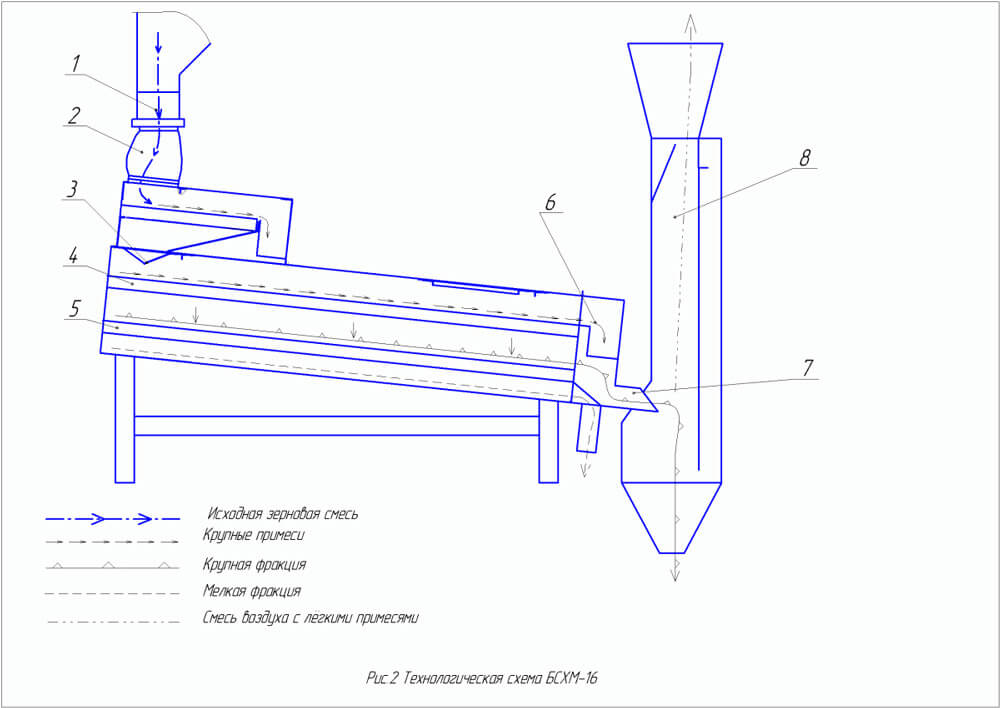

Grain-cleaning separator separates the initial grain mixture into fractions by successively sifting it through three tiers of sieves. The sieves make reciprocation motion and remove light impurities and dust from large fraction particles through flown up airs at pneumatic separation channel.

You can find the technological scheme on drawing 2. The raw grain moves into sieve of the 1st tier through inlet nozzle (1) and sleeve (2). The large impurities go out of separator through trays of the 1st tier. Remaining product moves into body distributer (3), sieves of the 2nd tier (4). Then, remaining product moves into the 3rd tier (5) and large impurities go out of separator through the upper channel of outlet device (6). The grain divided on fractions on the lower sieve. The large grain goes to pneumatic separation channel through channel (7). The light small grain go out through tray (9). The grain flown up by air in pneumatic separation channel. Therefore, the grain is cleaned by air from the light impurities and dust and grain goes to process according to the technological scheme.

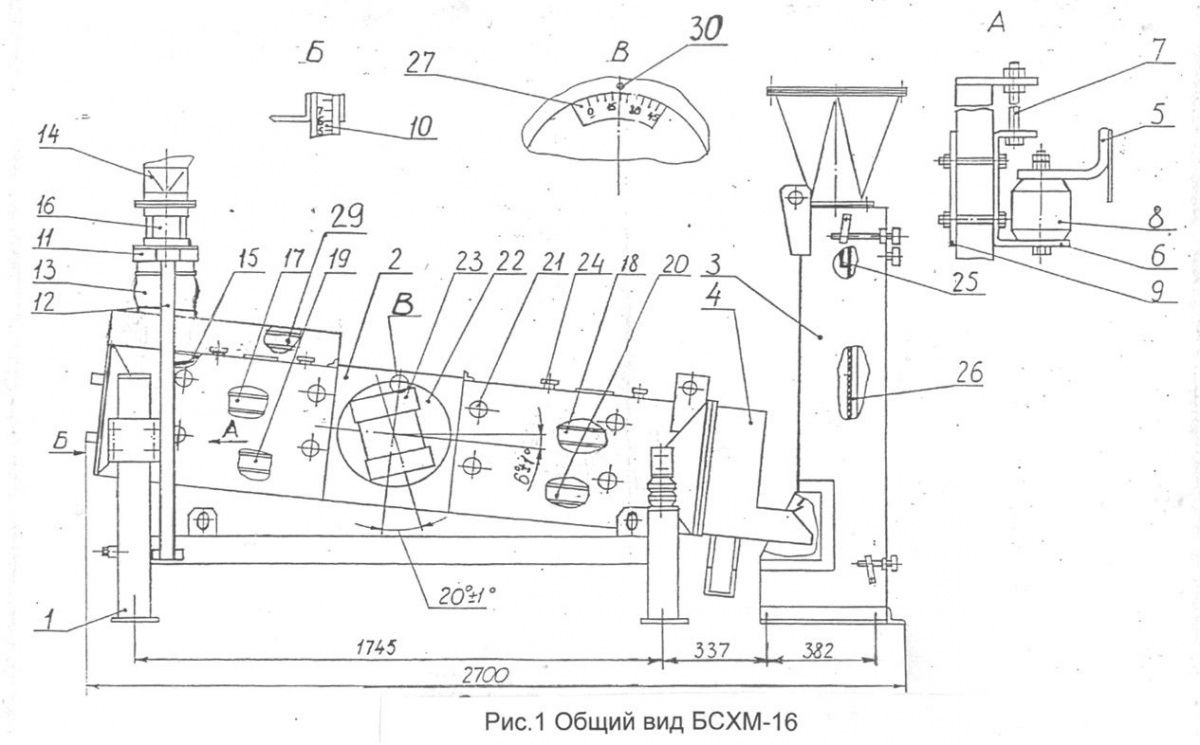

Design of Grain cleaning separator:

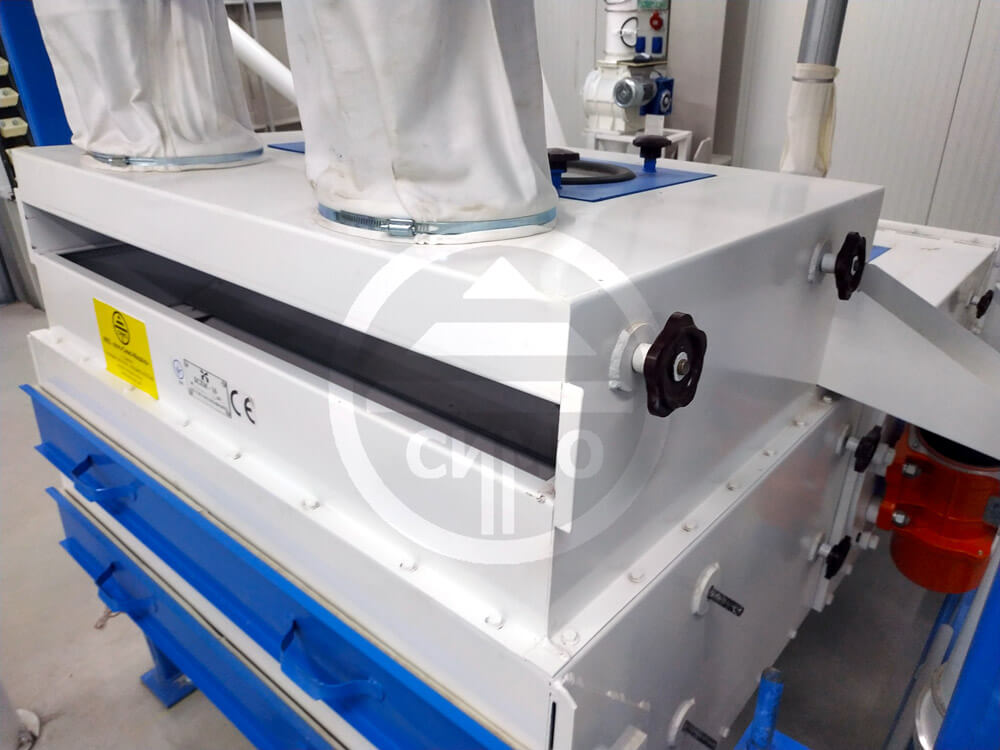

Grain-cleaning separator БСХМ-16 (drawing 1) consists of separator of large impurities dividing and pneumatic separation channel for dividing of light impurities and dust. Separator consists of bed, receiving device, body with sieve frames, outlet device.

The body (2) installed on the bed (1) due to brackets (5, 6) and rubber supports (8). Clamping planks (9) and bolts (7) allow to install the body in right position. The angle of inclination of the body can change from 0 to 10°. Receiving device consists of distributor (14); two nozzles (16) installed on crossheads (11) and racks (12): two sleeves (13), two nozzles on the body and on the distributor (15) for uniform supply of the product. The body is housing by steel with bottom. Inside, three-tiered sieve frames.

The customer choose sieves locally depending on raw product and its characteristics.