Purpose:

Pre-cleaning grain separator СПО-80 is designed for preliminary cleaning the incoming grain from the impurities. The raw grain is with a moisture content of up to 35% and waste impurity content of up to 20%. The separator works in the receiving and preparation departments of mills, elevators, the grain processing lines. The machine made according to 3rd category of State Standard (No 15150, climatic execution “У”).

Specifications:

| Name of indicators |

СПО-80 |

1. Productivity for wheat cleaning with a bulk weight 0,67 t/m3waste impurity content

of up to 10% (including straw up to 1%) with a moisture content of 20% |

Up to 80 t/h |

| 2. Installed capacity, kW |

11,0 |

| 3. Dimensions, mm |

|

| - length |

3 089 |

| - width |

1 828 |

| - height |

3 023 |

| 4. Rotation speed of fan roller, RPM |

827 |

| 5. Rotation speed of sieve roller, RPM |

68 |

| 6. Rotation speed of waste roller, RPM |

512 |

| 7. Weight, kg, max. |

1 500 |

-

Productivity for other grain

-

For other crops, the nominal productivity of the machine should be determined taking into account the factors given in the table:

| Name of culture |

Bulk weight, kg/m3 |

Conversion factor |

Mesh cell size* |

| Wheat |

760 |

1,00 |

15x15 |

| Corn |

700 |

1,00 |

20x20 |

| Peas |

800 |

1,00 |

20x20 |

| Beans |

850 |

1,20 |

20х20 |

| Spring barley |

720 |

0,85 |

15x15 |

| Rye |

700 |

0,90 |

15x15 |

| Winter barley |

650 |

0,80 |

15x15 |

| Soy |

720 |

0,75 |

20x20 |

| Hemp |

615 |

0,75 |

10х10 |

| Buckwheat |

650 |

0,70 |

15x15 |

| Spring vetch |

800 |

0,70 |

15x15 |

| Winter vetch |

800 |

0,60 |

15x15 |

| Sorghum |

750 |

0,60 |

10x10 |

| Rice |

700 |

0,50 |

15x15 |

| Sunflower |

355 |

0,40 |

20x20 |

| Sugar beet |

300 |

0,40 |

20x20 |

| Millet |

850 |

0,80 |

10x10 |

| Rape |

700 |

0,30 |

10x10 |

| Oats |

500 |

0,70 |

15x15 |

* Size of cell mesh can changed depend on size of grain and it accords with the Customer.

With an increase in the indicated norms of contamination and moisture content of the source material, the nominal productivity of the machine decreases by 2% - for each percentage increase in contamination and by 5% - for each percentage increase in moisture.

Design and operation:

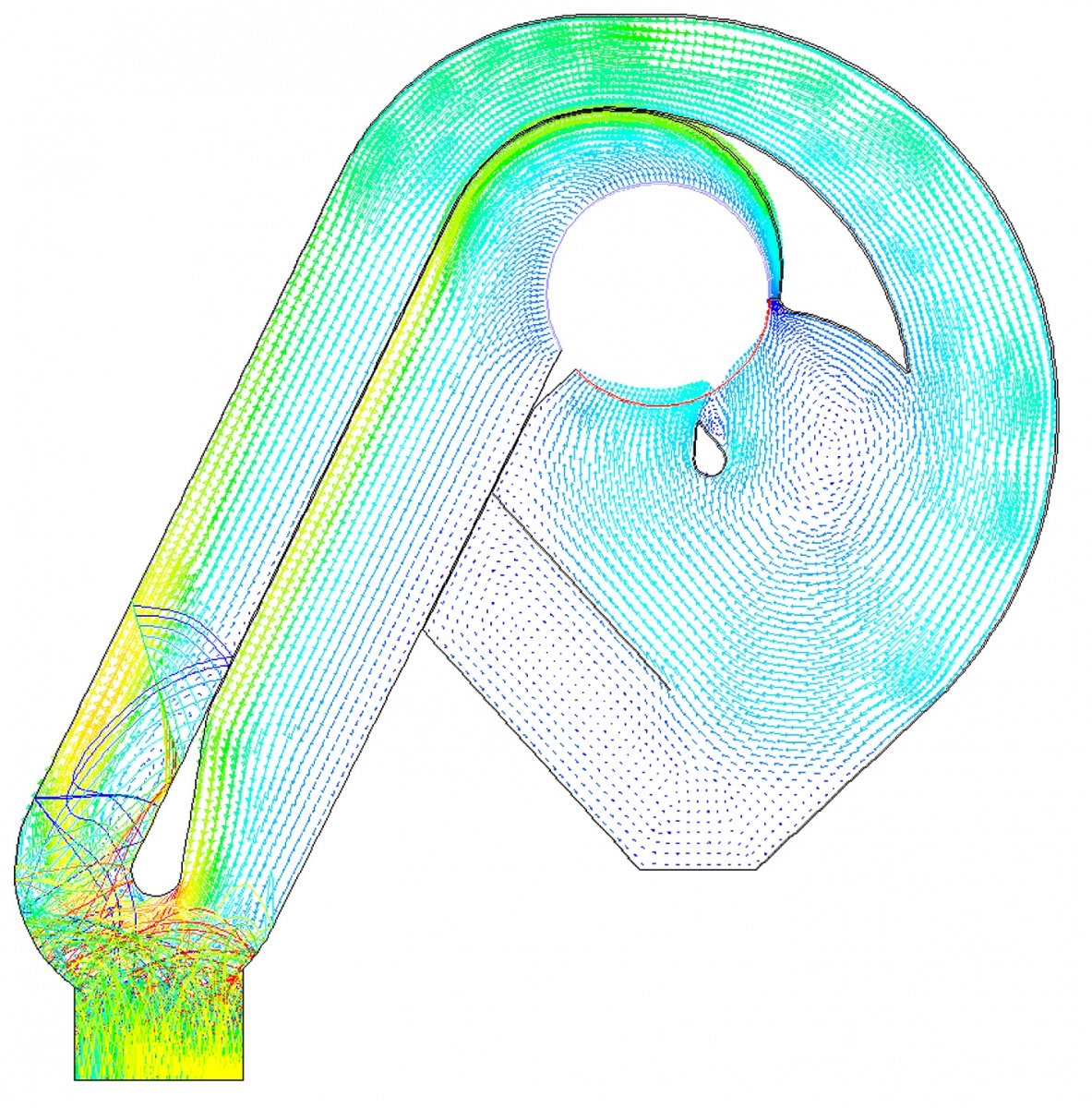

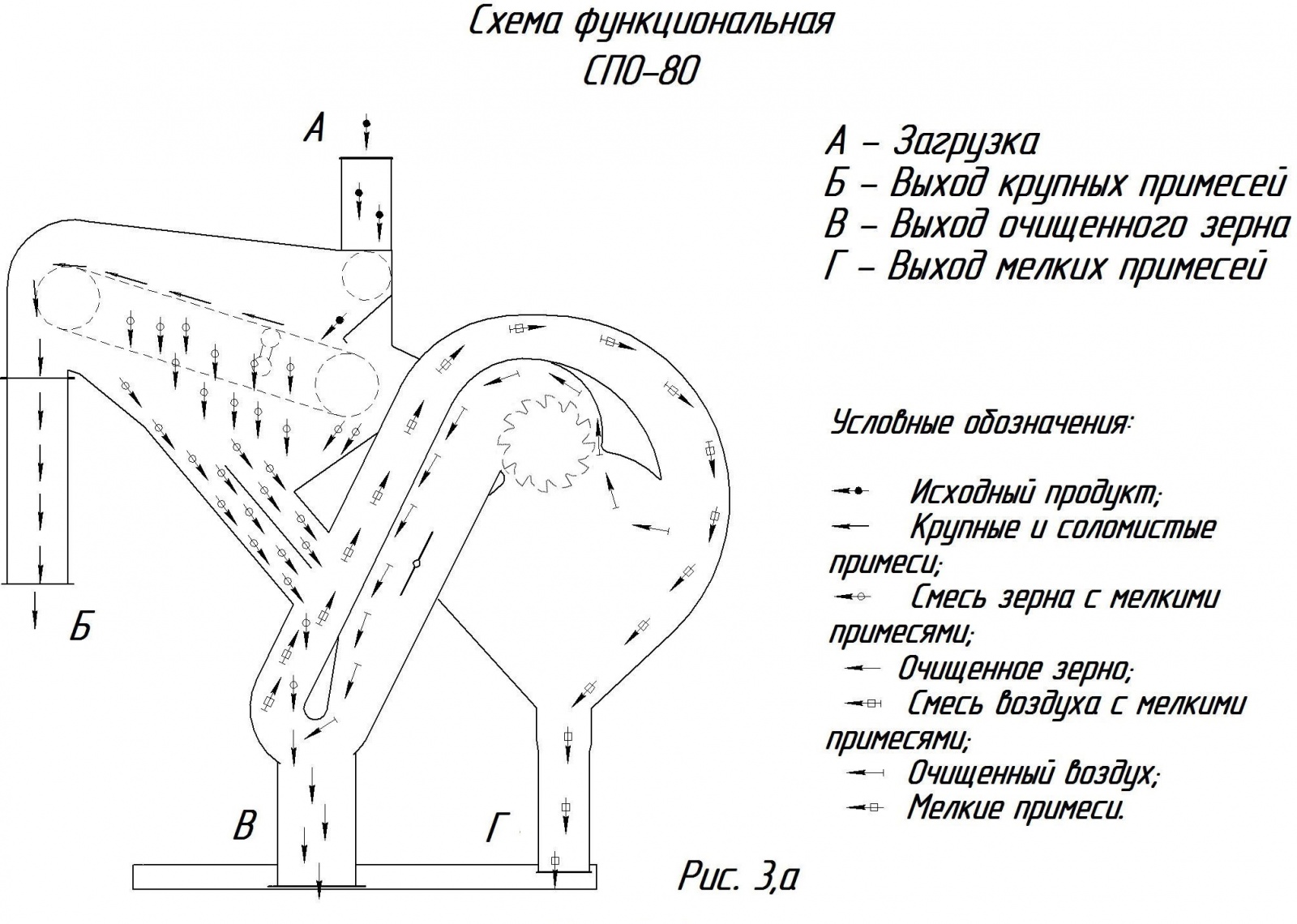

Pre-cleaning grain separator СПО-80 (drawing 1 a) consist of receiving chamber (1) and pneumatic separation system (2). These chambers made as assembled welded construction of sheet material.

Receiving chamber consists of distribution auger (3) with valve-feeder and controlled weights, infinite mesh transporter (4), bitter (5), slave valve (6), lead valve (7) with drive and supporting rollers, discharge hopper (8) for getting out of impurities (including straw).

There are diameter fan (rotor, 12) and unloading auger (13) to get waste out. In the lower part of the pneumatic separating channel there are two outlet nozzles (14) to get the cleaned grain out of separator. The grain go through receiving nozzle and distributing auger (3) to the pre-cleaning grain separator. Then the grain go to mesh transporter (4) by uniform layer. Afterwards, the grain with dust and small impurities through mesh move into the air separating area. Large impurities get up by mesh transporter and get out through hopper (8).