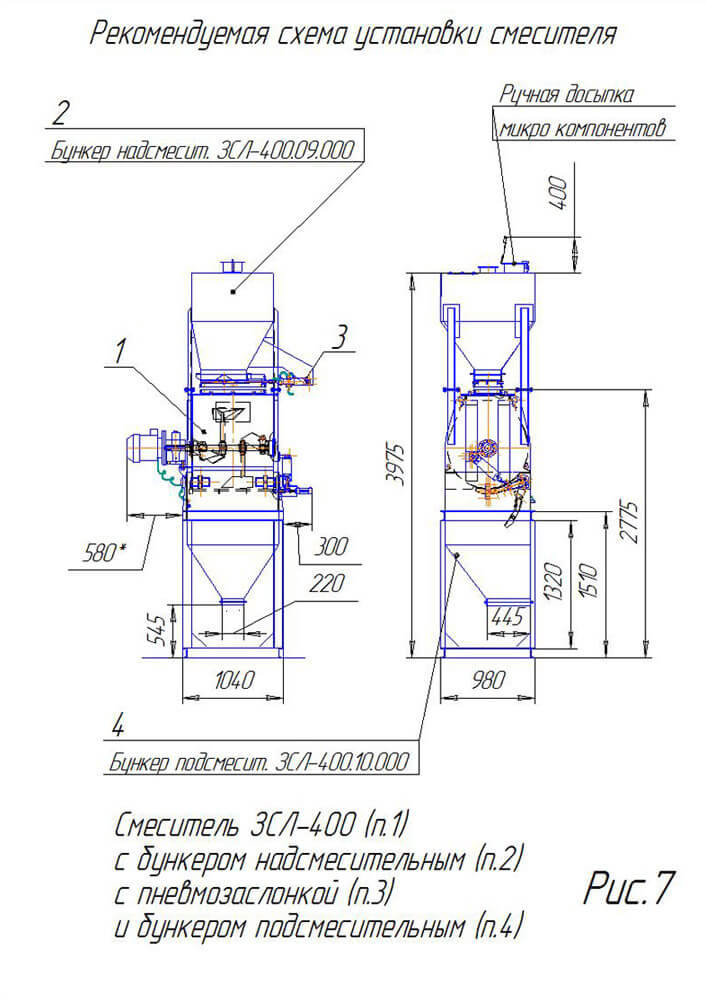

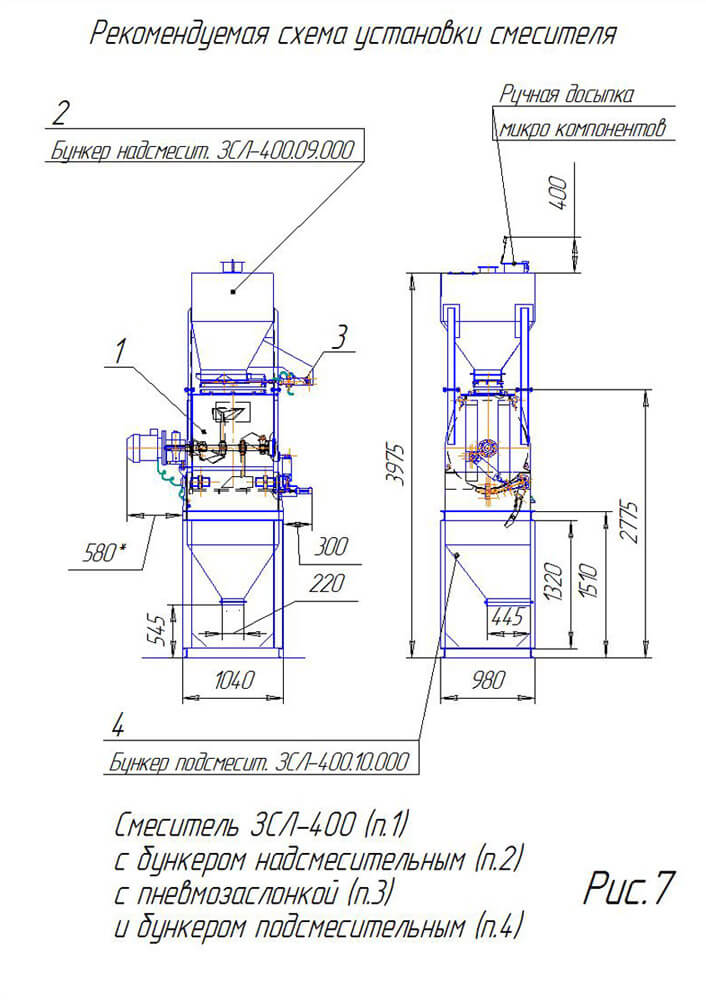

Purpose:

The Mixer ЗСЛ-4000 is designed for blending the premix components after these ingredients have been dosed. It's suitable for mixing mineral fertilizers. Dimensions of the individual mixing components should be in the range of 0.1 to 3.0 mm. The Mixer can be applied at the turnkey feedstuff plants and enrichment mixtures production workshops.

It perhaps to make Mixer Н-ЗСЛ-4000 for mixing of premix and food components. All the parts are in contact with the mixing products is made of stainless steel.

Specifications:

| Parameter |

ЗСЛ-400 |

| 1. Capacity, kg per cycle, max |

200 |

| 2. Volume, cubic meters |

0,4 |

| 3. Mix homogeneity rate, %, max |

95 |

| 4. Mixing cycle, min.: |

3,4 |

| - Loading time |

0,45 |

| - Mixing |

2,5 |

| - Discharge |

0,45 |

| 5. Rotor speed, RPM |

47 ± 3 |

| 6. Installed power, kW |

7,5 |

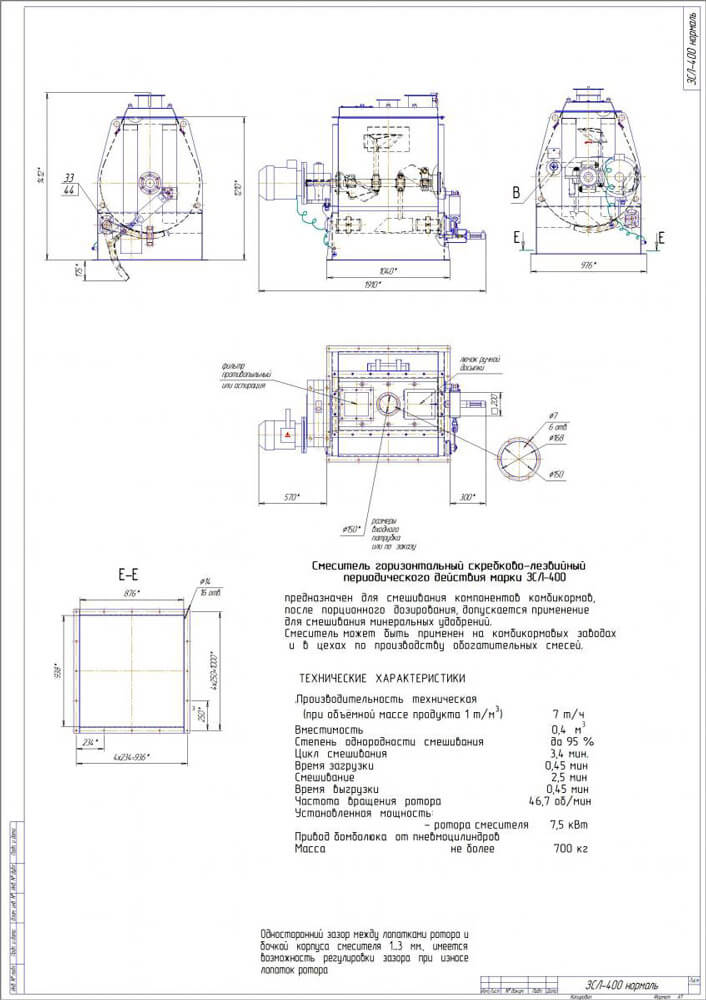

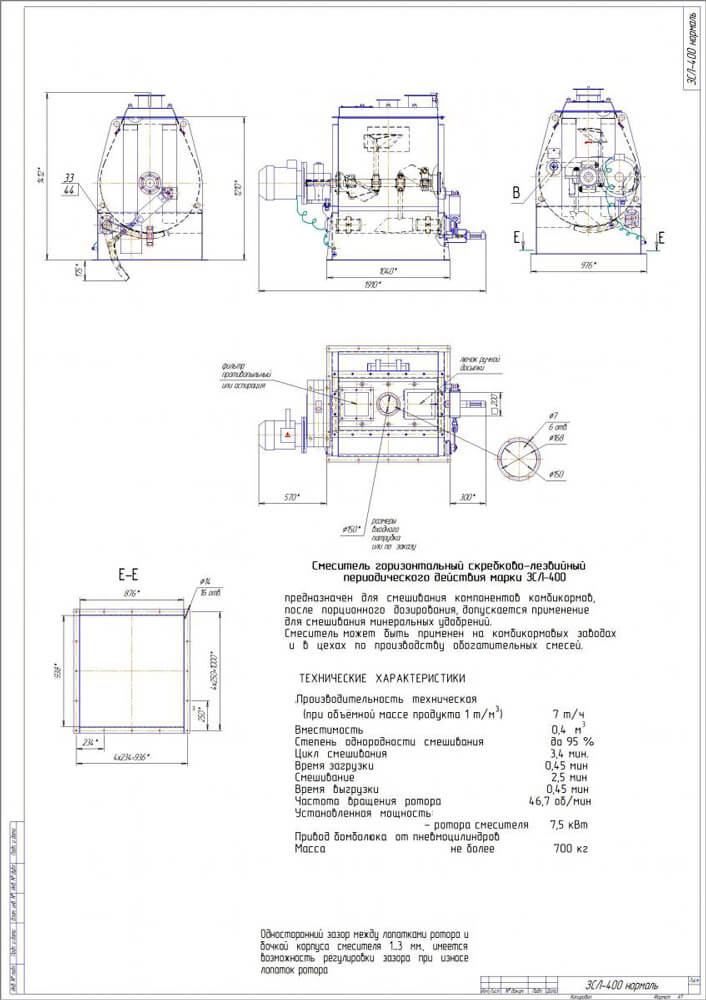

| 7. Dimensions, mm: |

|

| - length |

1 910 |

| - width |

980 |

| - height |

1 410 |

| 8. Weight, kg, max |

700 |

Design:

The mixer consists of body (1), rotor (2), drive (3), discharging hatch (4), pneumatic drive of discharging hatch (4), support device of discharging hatch (6). The body is steel welded semi-cylindrical construction. There are covered windows in the side walls of body. The windows linked to electric engine by switch. These windows are designed for repair works and visual control.

Rotor is a roller which have 4 paddles. The paddles are at specific angles. It provides intensive mixing of loading raw material. Rotor roller are supported by bearings, which installed on mixer body. Driver provides necessary frequency of rotor rotation due to reducer. Discharging hatch consists of door leaf curved along the radius. Discharging hatch has welded plates and stiffeners. The leaf is installed on roller due to levers. Opening and closing of discharging hatch are due to pneumatic cylinder.

Principle of operation:

The principle of operation is that the fillers entering the mixing hopper accumulate until the batch / level is reached. Then the dosed components are loaded in manual mode. Short loading time prevents delamination of components. When the rotor rotates, the components are subjected to intense counter-mixing by the paddles in the mixer body. After the mixing time has finished, the discharging hatch opens and the resulting mixture is sent to the place of unloading from the body. Unloading control is carried out manually or using automation (PC).