Purpose:

Shaft dryer СШ is designed to dry cereal grain and groats.

Premium (part number СИМО.СШ-001). This kind of machine should be used for drying of cereal grain and groats of high humidity, because bodies and other part, which contact product, made in stainless steel. The walls made in galvanized steel.

Standard (part number СИМО.СШ-002). This kind of machine can be used for drying of unhulled grain. All parts, which contact product, made in galvanized steel.

At customer require, it is perhaps to order so separate spare parts as boxes, walls, adapters etc.

Specifications:

| Name of indicators |

СШ (2 sections) |

СШ (3 sections) |

| 1. Number of sections, pcs. |

2 |

3 |

| 2. Grain volume in the dryer, m3 |

3,07 |

4,28 |

| 3. Productivity, t/h: |

|

|

| - oats |

0,5 ... 0,8 |

0,8 ... 1,0 |

| - buckwheat |

0,5 ... 0,8 |

0,8 ... 1,0 |

| - pea |

1,5 ... 1,8 |

2,8 ... 2,2 |

| 4. Product volume in one section, m3 |

1,21 |

1,21 |

| 5. Grain humidity at the entrance to the dryer, max., % |

20 |

20 |

| 6. Steam pressure, kPa |

400 |

400 |

| 7. Steam consumption, kg/s |

0,025 |

0,038 |

| 8. Air flow consumption, m3/h |

4 000 |

8 000 |

| 9. Power of electric motor, kWt |

2,2 |

2,2 |

| 10. Dimensions, mm |

|

|

| - length |

2 130 |

2 130 |

| - width |

2 300 |

2 300 |

| - height |

3 860 |

4 710 |

| 11. Weight, kg |

1 400 |

1 900 |

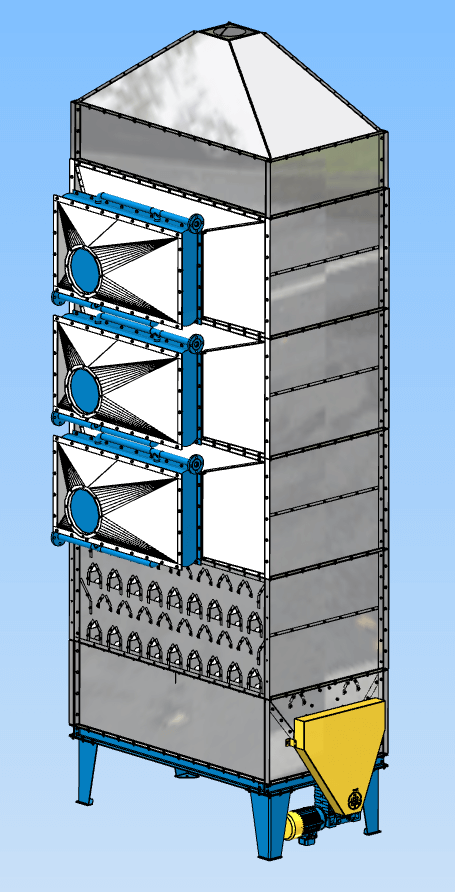

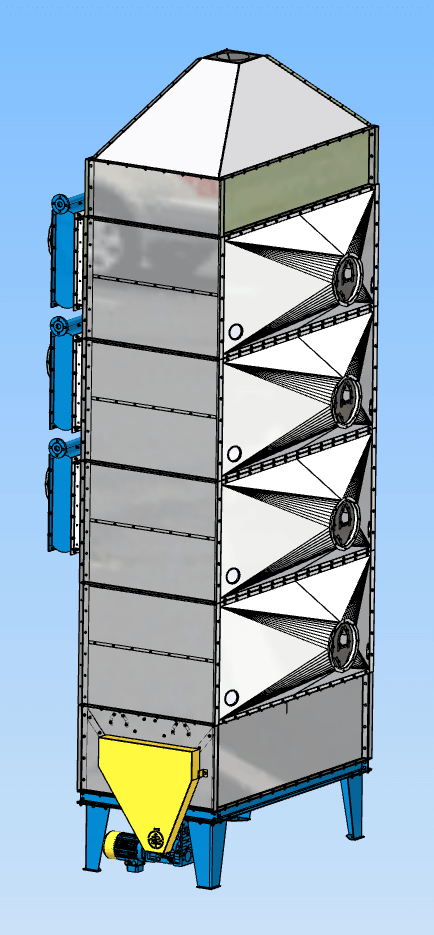

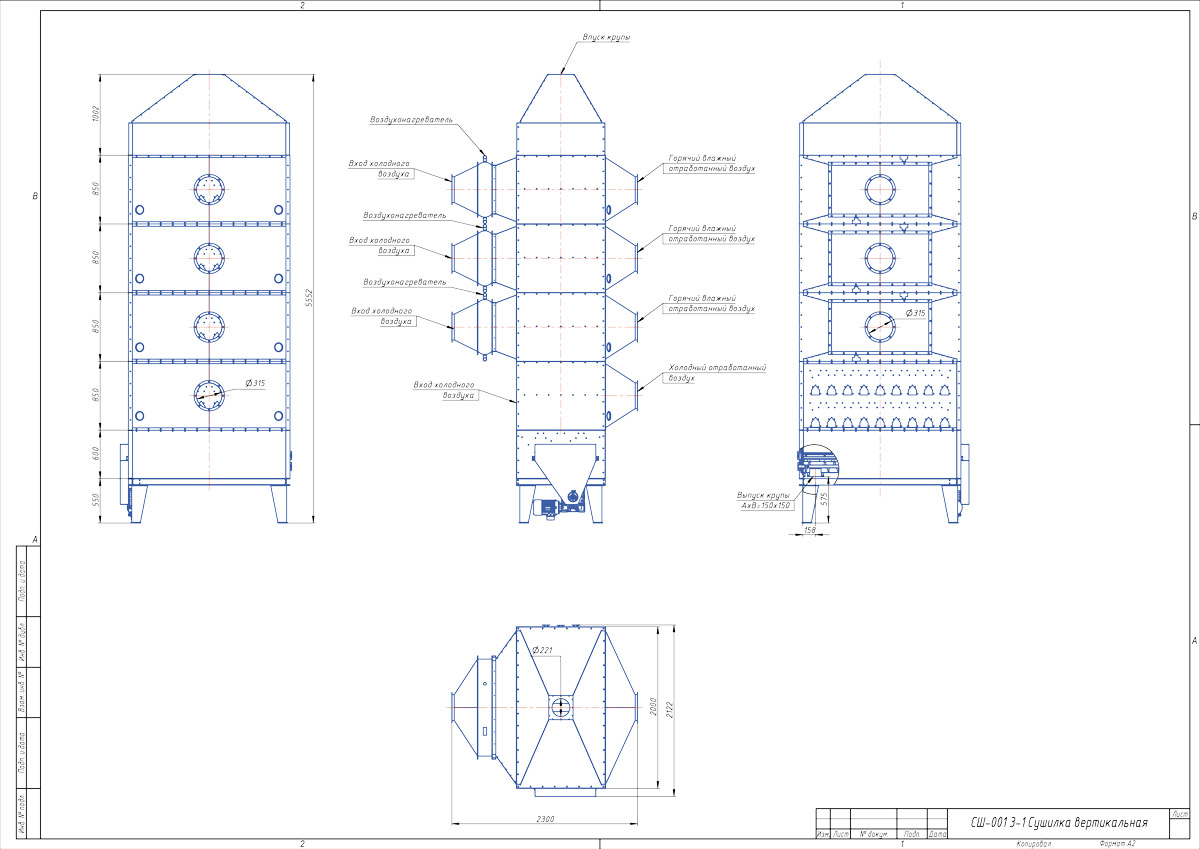

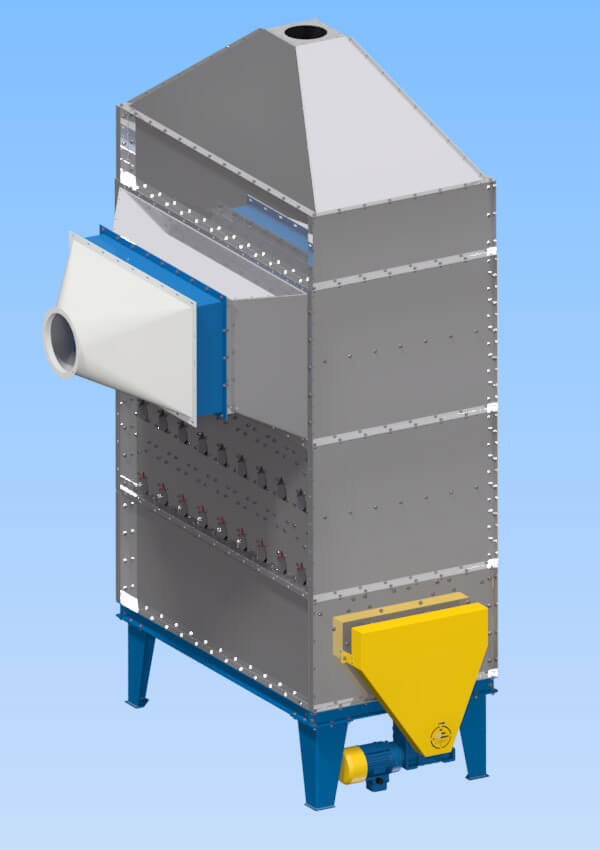

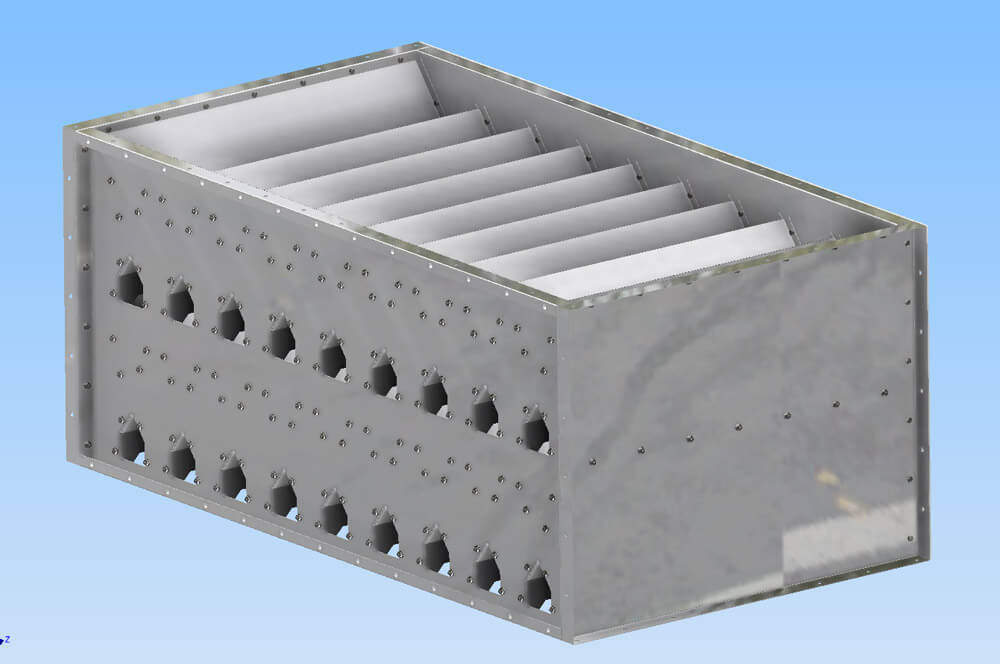

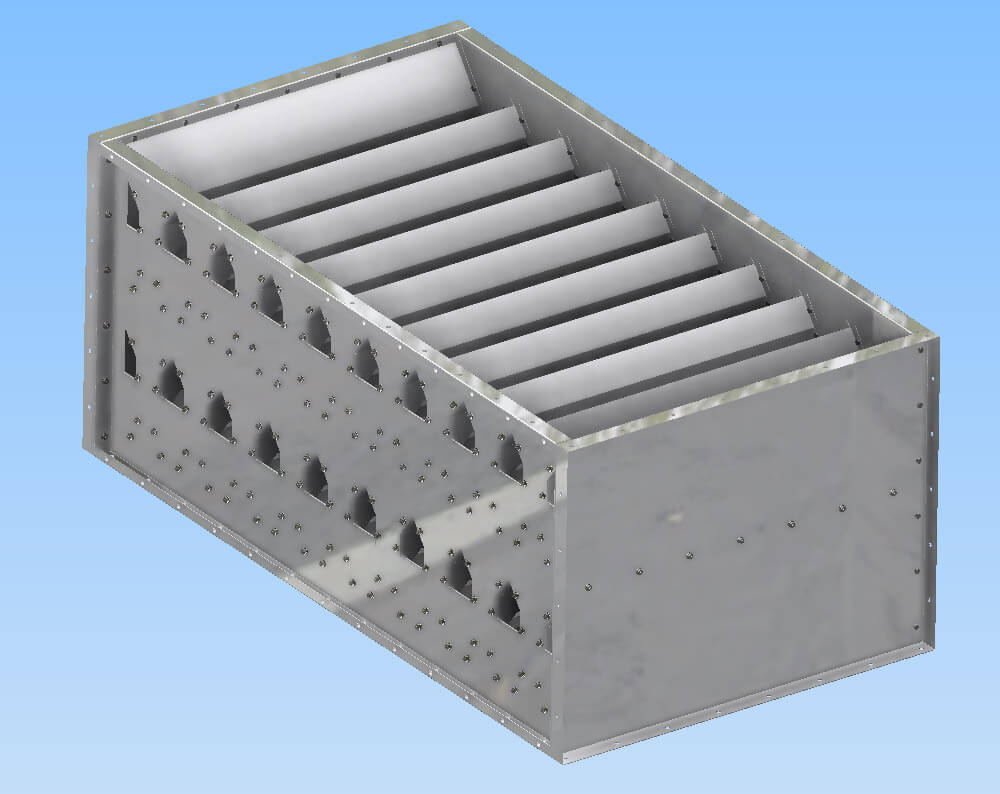

Design of the Shaft dryer СШ:

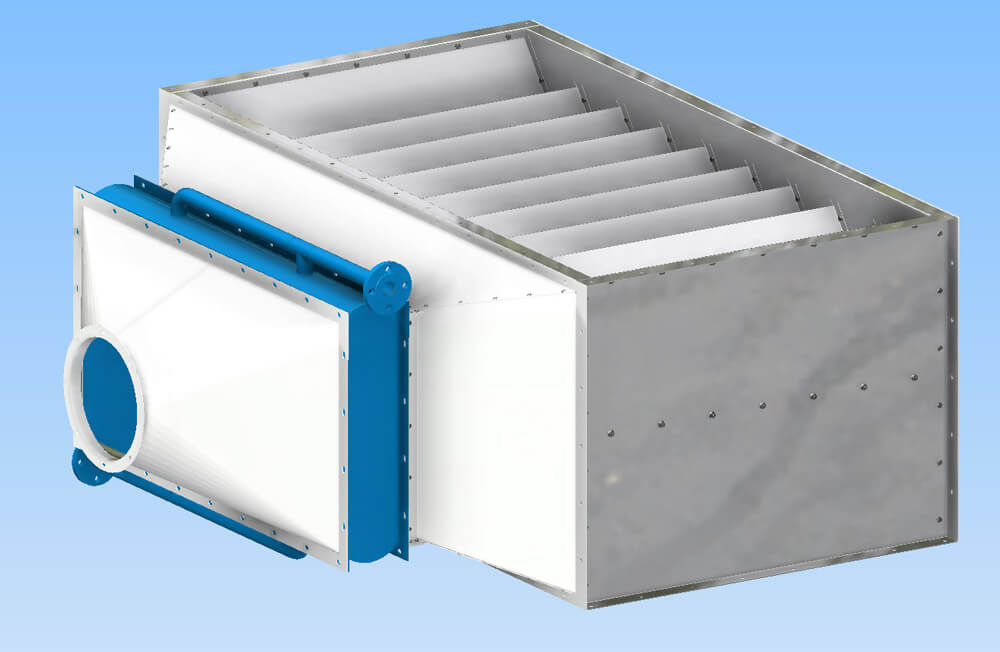

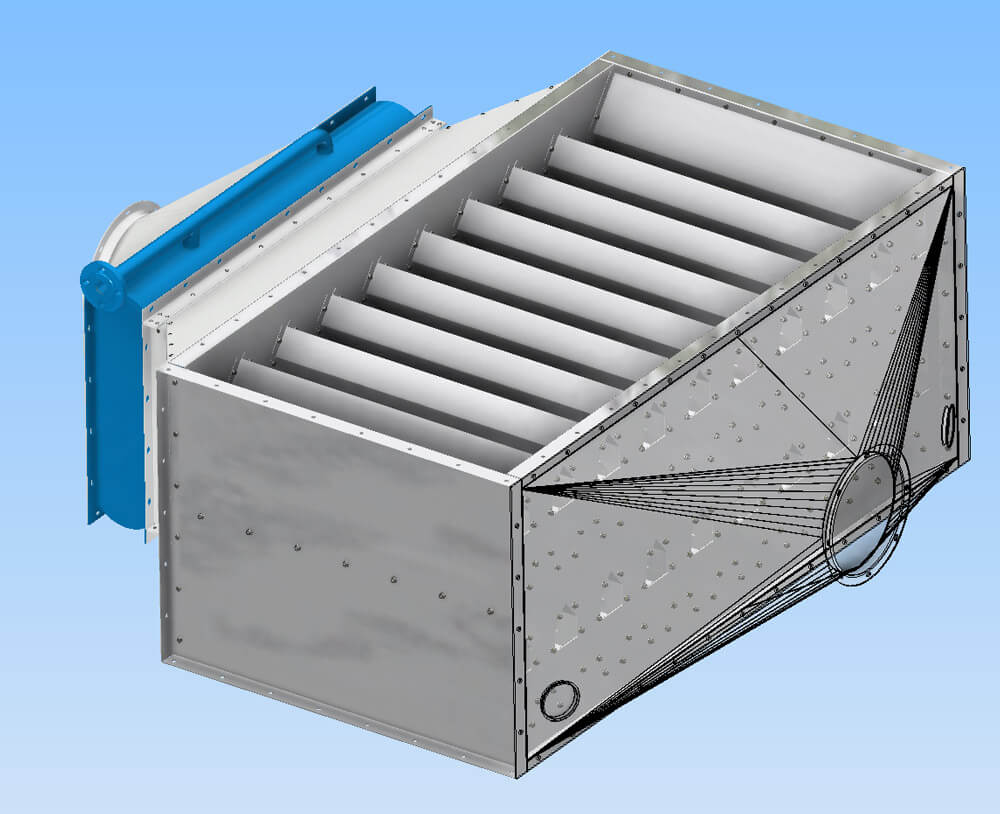

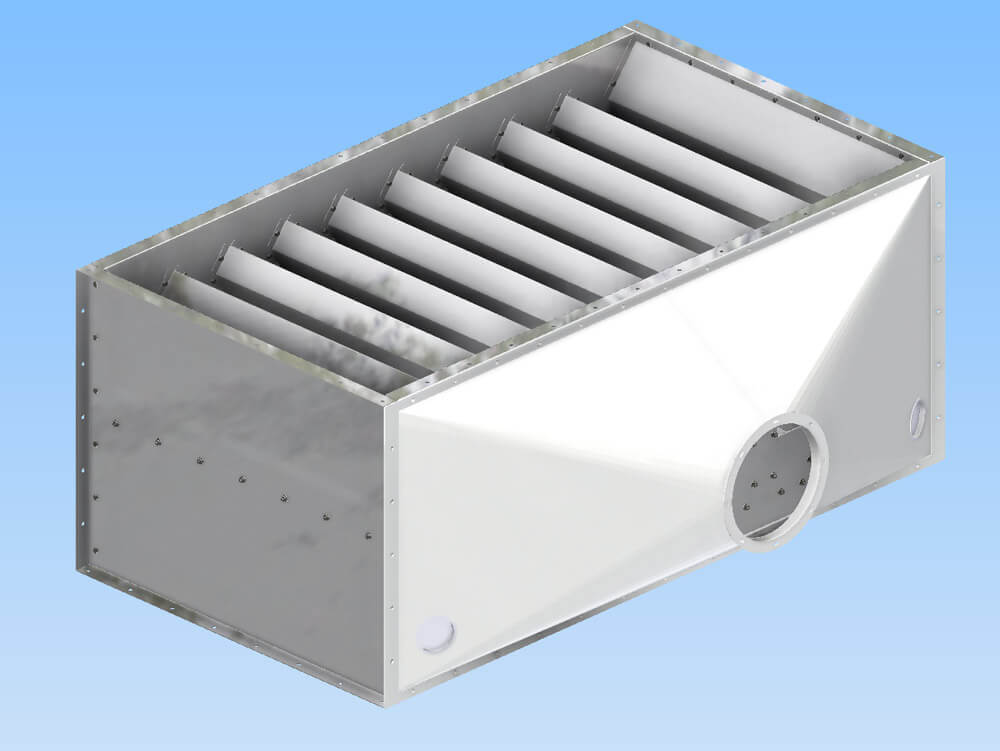

It consists of receiving distributing hopper, drying sections, cooling section, unloading device, heaters, frame and transition nozzles.

There is the section with box in the basic of the machine. The boxes are installed by checkerboard pattern for uniform distribution of the drying agent among the volume of grain filling the section.

The drying section consists of section with boxes, heater with adapters and switch on aspiration adapter. Half of the boxes are “hot”, because the hot air goes from the heats through these boxes. Other boxes are output. Processed air, which contacted grain, goes out through those boxes.

The cooling section consists of section with boxes and switch on aspiration adapter. All boxes are “cool” in this section, because cold air flow goes out through these boxes.

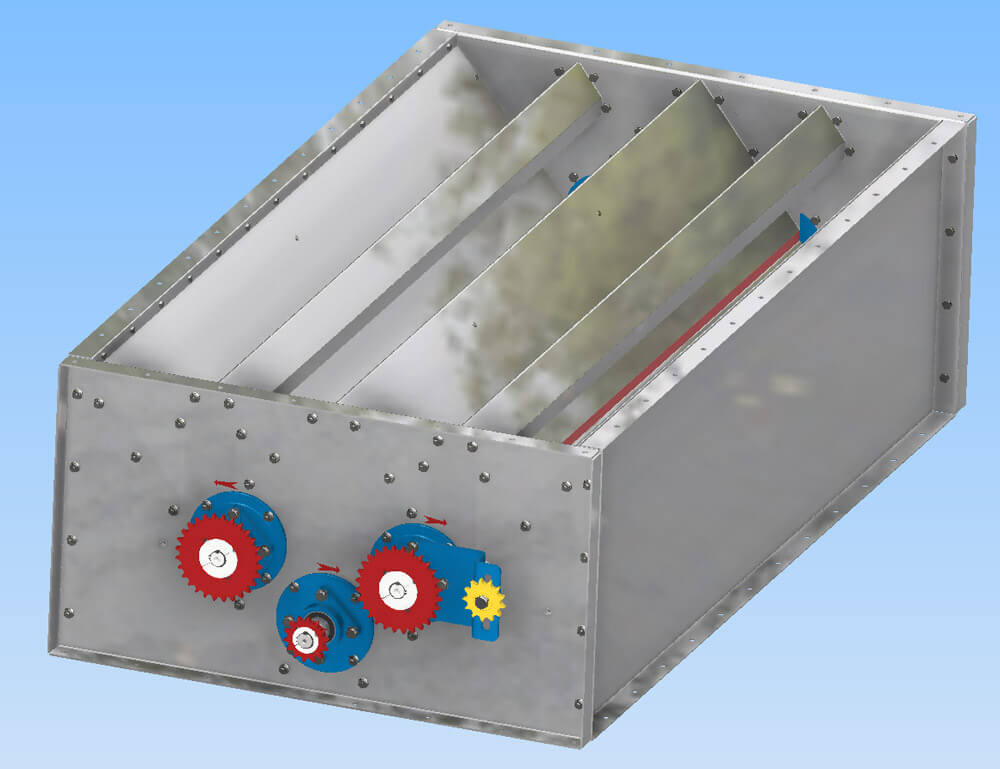

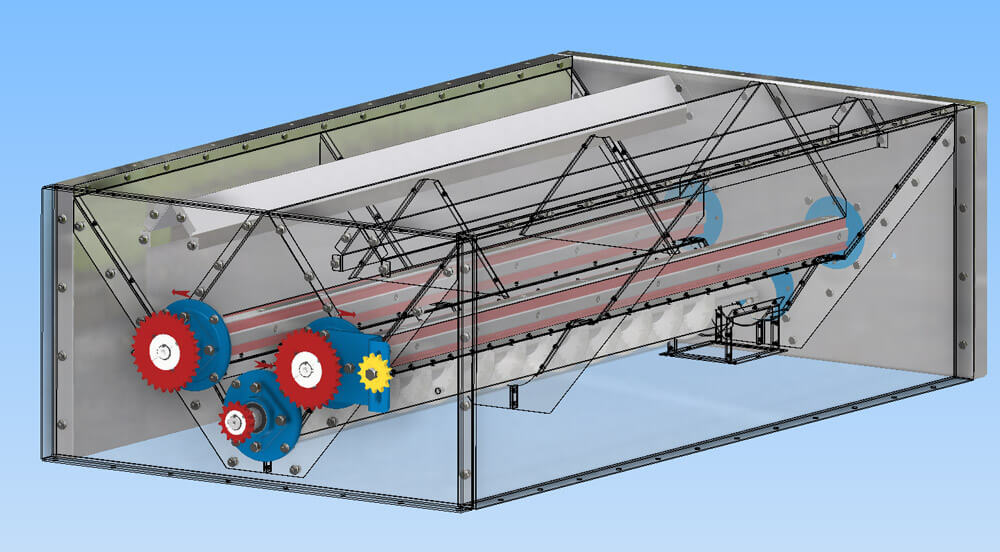

The Unloading section consists of two discharging shafts and screw, which installed in bodies of bearings. Construction of the unloading sections and screw reduce the chance of damage to grain or cereals.

We recommend to provide for frequency converter of unloading section drive. It's comfort to adjust of dryer productivity. If necessary, it is possible to easily change the speed of the unloading shafts and auger by replacing the drive sprockets, which are standard.