Premises. The most economical way is to use existing premises and reconstruct them, adapting for the new production process. This will cut capital investments significantly. Otherwise, it is feasible to erect a hangar-type building which will protect the equipment from precipitation and cold. The equipment set is placed in a hangar, size 12×24m, height 10 m to the bottom framework (truss).

In this type of building the function of floors is performed by multilevel steelwork landings, installed on their foundations filled inside the hangar. All the required core and auxiliary rooms are also provided inside the building (power distribution station, ventilation chamber, control panel etc.) The estimated total metal quantity for the mezzanine floors, structural steel, processing bins and waste bins - 70-75 t.

Power resources supply. . The installed power of the wheat/barley processing equipment is 264,0 kW; of pea processing equipment is 245,0 kW.

To steam and dry it is required to provide saturated steam. The steam flow for processing one ton of grain is 500-700 kg. Steam pressure at the steam distribution comb in the production shop is 0,7…0,9 MPa. Therewith it is more reasonable to use the boilers, powered by hull, or to adapt the boilers, powered by solid fuel, to hull combustion.

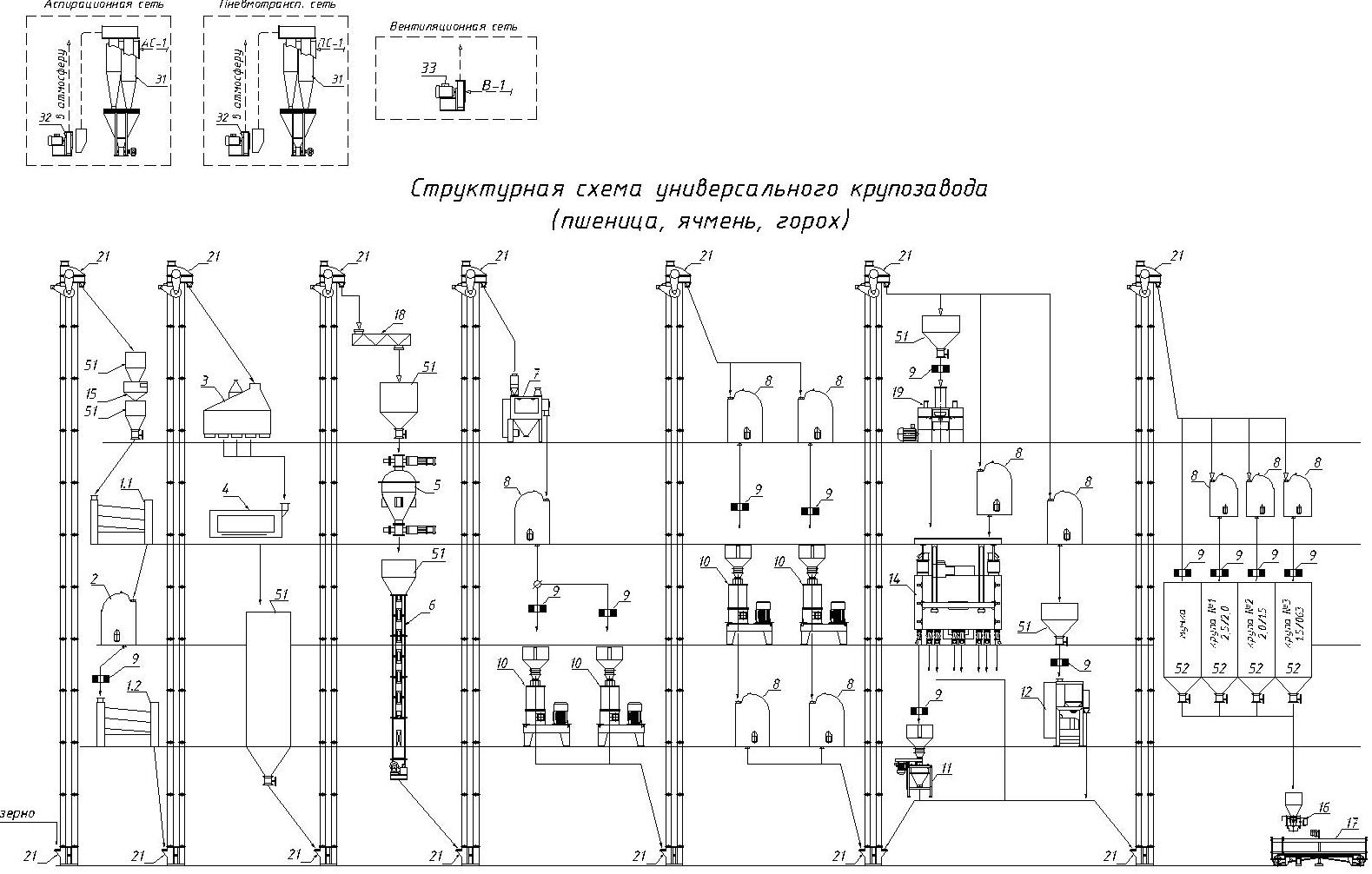

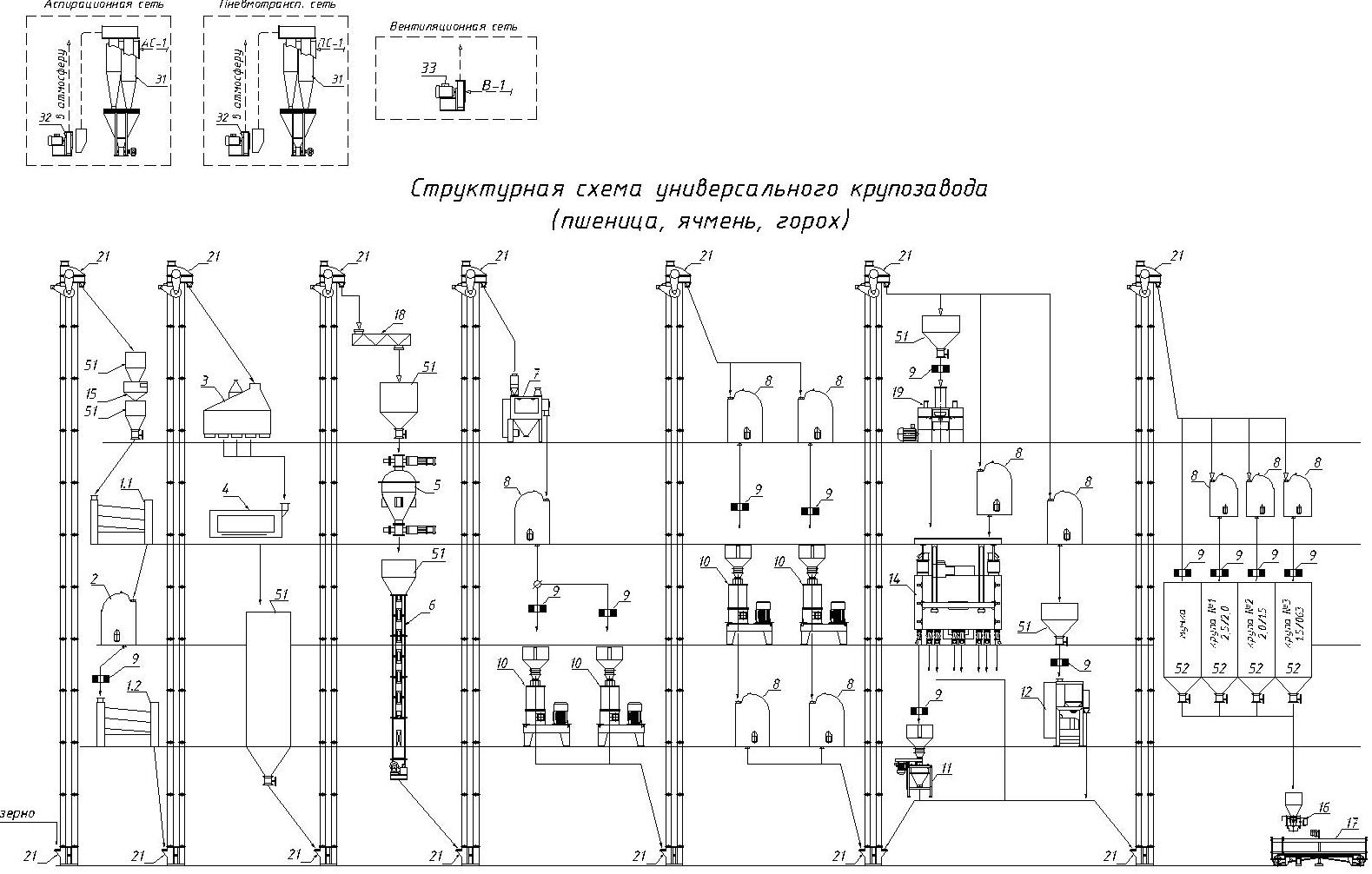

The list of essential equipment:

| Position |

Name |

Code |

| Process equipment |

| 1 |

Bin scales |

"Норма-ТМ" |

| 2 |

Grain cleaning separator |

БСХ-12 |

| 3 |

Stone separator |

Р3-БКТ-100 |

| 4.1 … 4.13 |

Grain cleaning separator |

Б8-БМП |

| 5 |

Grain cleaning separator |

БСХМ-16 |

| 6.1, 6.2 |

Self-balancing sifting machine |

РК-2 |

| 7 |

Cylinder separator (oat cylinder) |

Р6-ТЦ-700 |

| 8 |

Screw conveyor (steam) |

Ш-200 |

| 9 |

Steamer |

ПЗ-2 |

| 10.1, 10.2 |

Dryer |

ВС-10М |

| 12.1…12.4 |

Air separator |

АСХ-10 |

| 13 |

Horizontal huller |

БГО-6 |

| 15.1 … 15.4 |

Hulling and polishing machine SIMO |

ШШМС-3 |

| 16.1, 16.2 |

Grinder |

ИС-1 |

| 17.1 … 17.6 |

Air separator |

АСХ-5 |

| 18 |

Degerminator SIMO |

ДС-2 |

| 19 |

Self-balancing sifting machine |

РК-4 |

| 20 |

Centrifugal sieve |

ЦС-1 |

| 21 |

Batch doser |

"Norma-С" |

| 22 |

Bag packer |

К4-БУВ |

| Transport equipment |

| 31.1 … 31.18 |

Bucket conveyor |

Н-5/16 |

| 32.1 … 32.18 |

Explosion vent |

ВЗРВ-200 |

| 33.1..33.4 |

Screw conveyor |

Ш-160 |

| Ventilation and aspiration system equipment |

| 41.1, 41.2 |

Fan |

ВРП-4.3 |

| 41.3 |

Fan |

ВРП-4.5 |

| 41.4 |

Fan |

ВРП-4.4 |

| 41.5, 41.6 |

Fan |

ВРП-3,15.1 |

| 41.7 |

Fan |

ВРП-4.4 |

| 41.8 |

Fan |

ВРП-4.2 |

| 42.1...42.4 |

Fan |

ВРП-6,3.1 |

| 42.5 |

Fan |

ВРП-3,15.1 |

| 43.1, 43.2 |

Battery cyclone unit with a gate valve |

ББЦп-300 |

| 43.3, 43.4 |

ББЦп-400 |

| 43.5 |

ББЦп-250 |

| 43.6 |

ББЦп-200 |

| 43.7 |

ББЦп-450 |

| 43.8 |

ББЦп-350 |

| 44 |

Cyclone with an air lock and a drive |

ЦОЛ-4,5 |

| Bins |

| 51 … 57 |

Bins |

|

| Additional equipment |

| 11.1 … 11.4 |

Gate valve |

КОР-12 |

| 14.1 … 14.4 |

Divider |

КДР-7 |

| 23.1 … 23.13 |

Rack and pinion gate |

ТЗР-200 |

| 24.1 … 24.4 |

Rack and pinion gate |

ТЗР-300 |

| 25.1 … 25.4 |

Steam air heater |

ПНП113-304-02 |

| 61 |

Receiver |

--- |

| 62.1, 62.2 |

Centrifugal horizontal pump |

2К-6а |

| 63 |

Condensate tank |

--- |

| 64.1, 64.2 |

Turbine pump |

VK-1/16 |

| Total installed power Ntotal = 311,27 kW |

The process equipment set for the universal groats mill may be delivered without a hydrothermal treatment unit. In this case the lines to be excluded from the specification are:

| Position |

Name |

Code |

| 8 |

Screw conveyor (steam) |

Ш-200 |

| 9 |

Steamer |

ПЗ-2 |

| 10.1, 10.2 |

Dryer |

ВС-10М |

| 31.3 |

Bucket |

Н-5/16 |

| 32.3 |

Explosion vent |

ВЗРВ-200 |

| 42.1...42.4 |

Fan |

ВРП-6,3.1 |

| 42.5 |

Fan |

ВРП-3,15.1 |

| 25.1 … 25.4 |

Steam air heater |

ПНП113-304-02 |

| 61 |

Receiver |

--- |

| 62.1, 62.2 |

Centrifugal horizontal pump |

2К-6а |

| 63 |

Condensate tank |

--- |

| 64.1, 64.2 |

Turbine pump |

VK-1/16 |