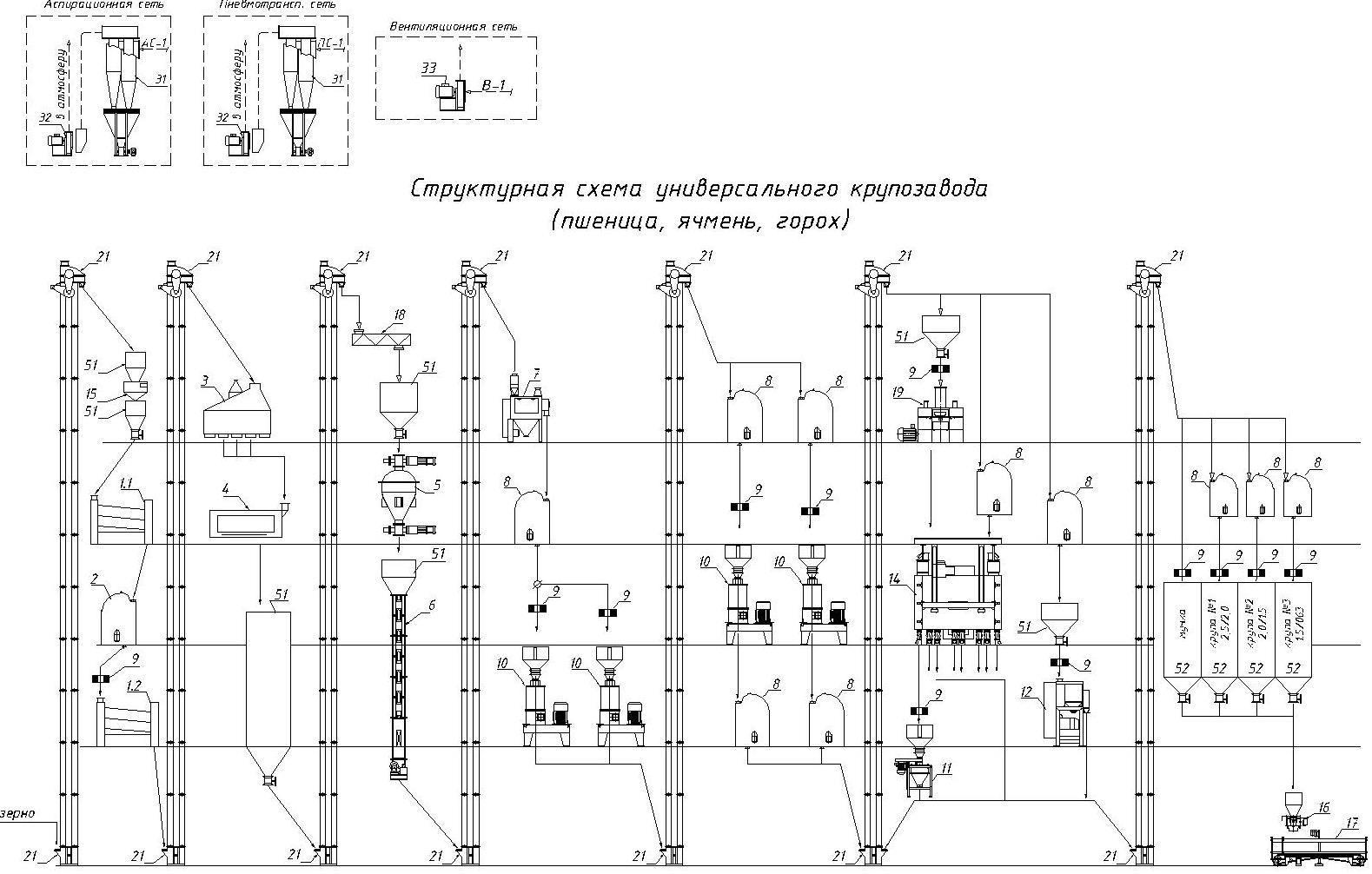

Uses. The process equipment set is designed for processing a number of grain crops: wheat, barley and pea. The specific feature of this buckwheat cereal process technology is its interchangeability of the process flow with the possibility to process millet grain into polished millet cereal.

The universal compatible process flow is flexible and allows for manufacturing products from the above crops on the same process equipment. Transferring from one crop to another requires replacement of sieves in sifting machines, gate valves, selection of the number of hulling systems and, respectively, adjustment of the operation mode for each piece of the process equipment. The specific feature of the interchangeable process flow is the use of the same grain cleaning compartment and the hydrothermal unit for the above grain crops, which enables to improve not only the grain process properties, useful qualities of the finished products, but also save energy costs for product hulling and polishing considerably.

Premises. The most economical way is to use existing premises and reconstruct them, adapting for the new production process. This will cut capital investments significantly. The equipment set is placed in a pre-fabricated or monolith concrete five storey building or a pre-fabricated metalwork building, faced with sandwich panels. This building must have reinforced concrete floors, size in layout 12 × 18 m, the height of floors 1-4 is 3,0 m; the height of floor 5 – 5,5 m.

Power resources supply. The installed power of the wheat/barley processing equipment is 214,0 kW; of pea processing equipment is 224,0 kW.

To steam and dry it is required to provide saturated steam. The steam flow for processing one ton of buckwheat grain is 500 - 700 kg. Steam pressure at the steam distribution comb in the production shop is 0,6 … 0,8 MPa. Therewith it is more reasonable to use the boilers, powered by hull, or to adapt the boilers, powered by solid fuel, to hull combustion

Process flow control. The plant is controlled from a computerized workstation.

The required number of the service staff per shift is 8 people.

Operation mode is 24 hours a day: three shifts by 8 hours or 2 shifts by 12 hours each.

The actual output of cereal under processing the grain of basic conditions (high-silicon varieties):

- Pearl barley cereal (5 grades) – 73 - 75 %;

- Fine barley (3 grades) – 78 - 80 %;

- Wheat cereal – 75 - 78 %;

- Pea cereal – 82 - 83 %.

Process equipment set

| Position |

Name |

Code |

| Essential process equipment |

| 1.1, 1.2 |

Grain cleaning separator |

БСХ-3 |

| 2 |

Air separator |

АСХ-5 |

| 3 |

Gravity table separator |

ПСС |

| 4 |

Cylinder separator (cockle cylinder) |

БТХМ-2-02 |

| 5 |

Steamer (0,5 m³) |

ПЗ-2 |

| 6 |

Dryer (5 drying units + 1 cooler) |

ВС-10М |

| 7 |

Horizontal huller (abrasive cylinder) |

Р3-БГО-6 |

| 8.1… 8.10 |

Air separator |

АСХ-2,5 |

| 9.1… 9.12 |

Magnetic separator |

Б8-БМП |

| 10.1… 10.4 |

Hulling and polishing machine |

Р6-МШ |

| 11 |

Grinder |

ИС-1 |

| 12 |

Degerminator СИМО |

ДС-2 |

| 14 |

Self-balancing sifting machine |

РК-4 |

| 15 |

Bin scales |

Норма-ТМ |

| 16 |

Semiautomatic batch doser |

Норма-С |

| 17 |

Bag packer |

К4-БУВ |

| 18 |

Screw conveyor (steam) |

Ш-200 |

| 19 |

Rolling mill |

ВМ-2П |

| 20 |

Horizontal huller |

Р3-БГО-6 |

| Transport equipment |

| 21.1 … 21.15 |

Bucket conveyor |

Н-5 |

| 22.1 … 22.15 |

Explosion vent |

ВЗРВ |

| 23.1, 23.2 |

Screw conveyor |

Ш-160 |

| Ventilation, aspiration and pneumatic transport system equipment |

| 31.1 |

Battery cyclone unit with a gate valve |

ББЦп-550 |

| 31.2 |

ББЦп-350 |

| 31.3 |

ББЦп-450 |

| 31.4 |

ББЦп-450 |

| 31.5 |

ББЦп-275 |

| 31.6 |

ББЦп-450 |

| 31.7 |

ББЦп-350 |

| 32.1 |

Fan |

ВРП-6,3.5 |

| 32.2 |

Fan |

ВРП-4.1 |

| 32.3 |

Fan |

ВРП-4.4 |

| 32.4 |

Fan |

ВРП-4.4 |

| 32.5 |

Fan |

ВВД-5 |

| 32.6 |

Fan |

ВРП-4.4 |

| 32.7 |

Fan |

ВЦ 6-28 №6,3 |

| 33.1 |

Fan |

ВРП-6,3.1 |

| 33.2 |

Fan |

ВРП-4.4 |

| 33.3 |

Fan |

ВВД-5 |

| 33.4 |

Fan |

ВВД-5 |

| 34 |

Pneumatic receiving unit |

"T-tube" |

| Additional equipment |

| 41.1 … 41.5 |

Steam air heater |

ПНП-113-304-02 |

| 42.1, 42.2 |

Condensate pump |

ВК-1/16 |

| 43 |

Receiver |

V = 1 m³ |

| 44 |

Condensate tank |

№10 |

| 45 |

Screw compressor |

Zenit 7,5 НР |

| 46.1 … 46.4 |

Flow divider |

КДР-7 |

| 47.1 … 47.13 |

Gate valve |

КОР-12 |

| 48.1 … 48.11 |

Slide gate valve |

--- |

| 49.1 … 49.4 |

Rack and pinion gate |

ТЗР-200 |

| 70.1, 70.2 |

Rack and pinion gate |

ТЗР-300 |

| Bins |

| 51 |

Processing bin |

|

| 52 |

Storage bin |

|

| Total installed power of wheat/barley processing - 214 kW |

| Total installed power of pea processing - 224 kW |

The process equipment set for the universal groats mill may be delivered without a hydrothermal treatment unit. In this case the lines to be excluded from the specification are:

| Position |

Name |

Code |

| 5 |

Steamer (0,5 m³) |

ПЗ-2 |

| 6 |

Dryer (5 drying units + 1 cooler) |

ВС-10М |

| 21.1 … 21.15 |

Bucket conveyor |

Н-5 |

| 18 |

Screw conveyor (steam) |

Ш-200 |

| 33.1 |

Fan |

ВРП-6,3.1 |

| 33.2 |

Fan |

ВРП-4.4 |

| 51 |

Processing bin (before hydrothermal treatment) |

V = 0,6 m³ |

| 52 |

Over-the-drier hopper |

V = 1,6 m³ |

| 41.1 … 41.5 |

Steam air heater |

ПНП-113-304-02 |